Air-conditioner panel adhesion process and air conditioner

A technology for air-conditioning panels and processes, applied in the directions of lamination, layered products, heating and ventilation hoods/covers, etc., can solve the problems of primers containing harmful substances, low production efficiency, and many processes, so as to reduce production costs, The effect of improving work efficiency and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

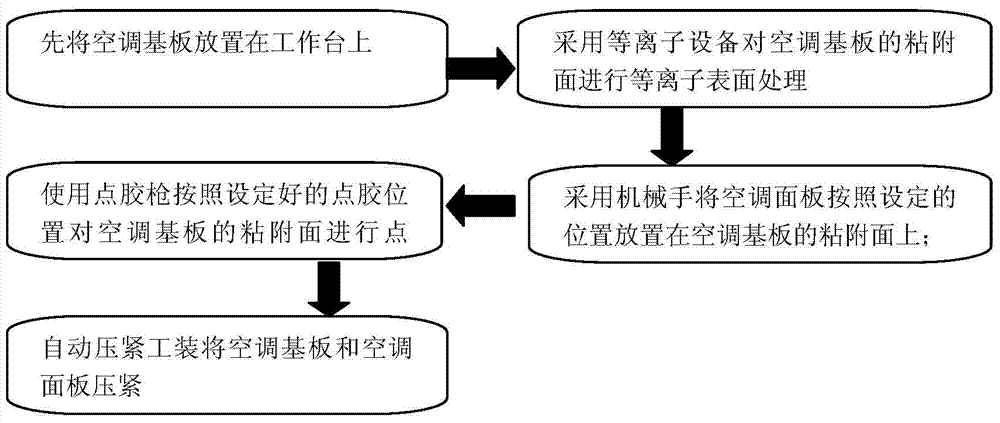

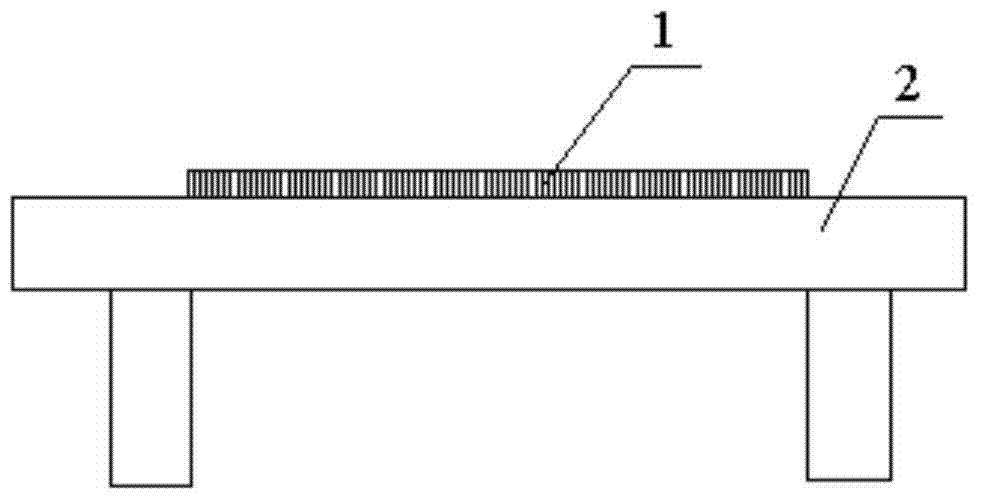

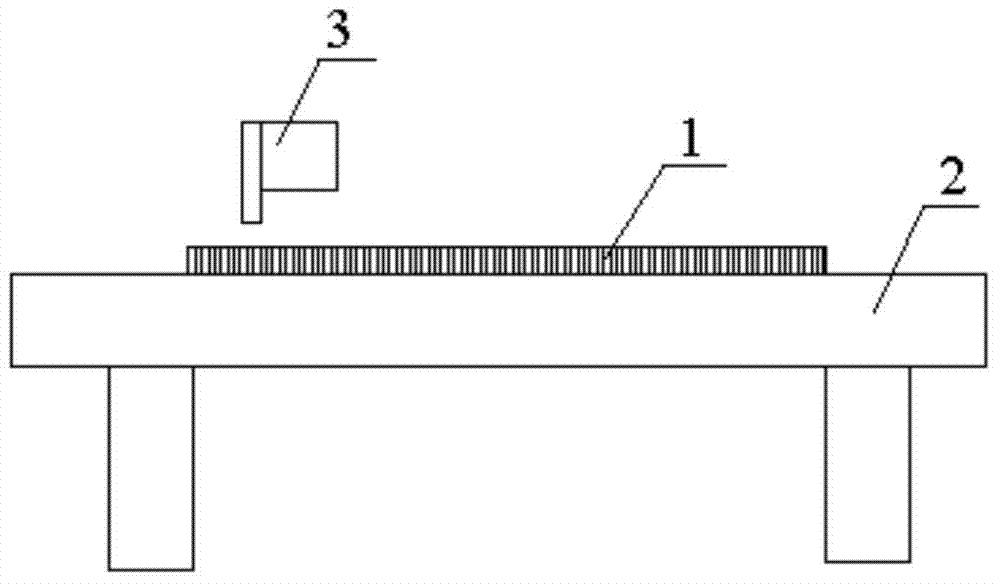

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0035] Most of the existing air-conditioning panels are made of ABS, PMMA, PBT, PA, HIPS, PC, PP, aluminum, tempered glass, etc. and their derivative materials. The surface is smooth and the adhesion is low. The way of sensitive glue is pasted, but still there will be the problem that the air-conditioning panel falls off from the air-conditioning substrate, which affects the aesthetics, reliability and service life of the air-conditioning.

[0036] Moreover, the amount of glue used in the paste method of primer + pressure-sensitive adhesive is relatively large, and has a certain impact on human health. At the same time, the paste method of primer + pressure-sensitive adhesive leads to the fact that the paste process of the air-conditioning panel must be done manually. Low efficiency, paste reliabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com