Adhesive tape pasting device

A sticking device and adhesive tape technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of easy detachment and insufficient firmness of the colloid, and achieve the effects of saving time, improving quality, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

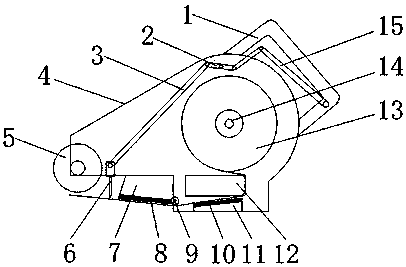

[0018] A tape sticking device, comprising a housing 4 and a handle 1, the left side of the housing 4 is provided with a compacting roller 5, the right side of the compacting roller 5 is provided with a blade 6, and the right side of the blade 6 is an adsorption block 7. The surface of the adsorption block 7 is an electrostatic adsorption layer 8, the right side of the adsorption block 7 is provided with a roller 9, the right side of the roller 9 is provided with a guide block 11, the surface of the guide block 11 is an isolation layer 10, and the top of the guide block 11 is a guide block 12, An adhesive tape fixing shaft 14 is arranged above the guide block 12, and an adhesive tape 13 is fixed on the adhesive tape fixing shaft 14. The handle 1 is arranged on the upper right side of the housing 4, and a pull rod 15 is arranged inside the handle 1, and the pull rod 5 passes through the connecting rod 2 and The connecting rod 3 and the hinge mechanism are connected with the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com