Insulation film pre-separation device

An insulating film and pre-separation technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of low efficiency and low paste quality, and achieve the effect of convenient extraction, easy direct grasping, and improved paste speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

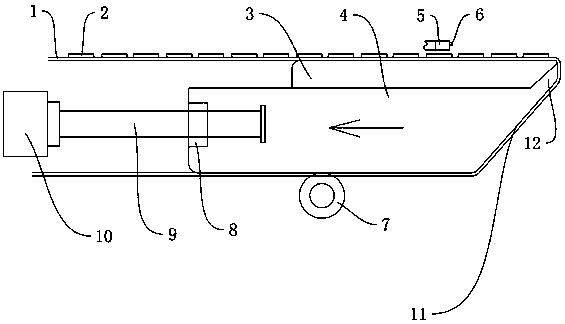

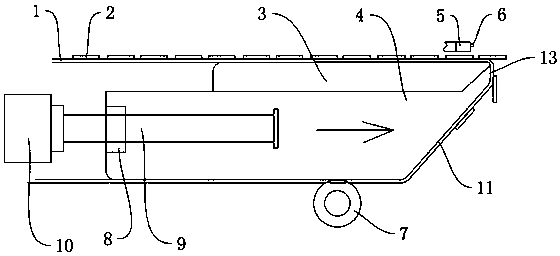

[0023] Embodiment: a kind of insulating film pre-separation device (see figure 1 ), including a frame and a moving assembly slidably arranged on the frame. The supporting surface of the film base tape 1 is above the moving assembly, and insulating films 2 are bonded to the film base tape at equal intervals. The moving assembly has an arc-shaped peeling angle, and the film base tape Go over the stripped corner from the support surface and make the turn.

[0024] The moving assembly includes a moving body 4 and a driving device that drives the moving body to move. The upper surface of the moving body is fixed with a moving slide 3. The upper surface of the moving sliding plate is the moving support surface of the film base tape. The driving device adopts a screw structure, and the moving body is hollow. Shape, the hollow end of the mobile body is fixed with a screw nut 8, the end of the screw mandrel 9 extends into the hollow of the mobile body, and the tail end of the screw man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com