7-cun general full-automatic high-speed carrier band winding equipment

A fully automatic and tape-carrying technology, which is applied in the direction of winding strips, sending objects, packaging, etc., can solve the problems of inability to adapt to various products, poor versatility of carrier tapes, and slow winding speed, so as to reduce damage to carrier tapes, Improve efficiency and reduce abnormal equipment alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

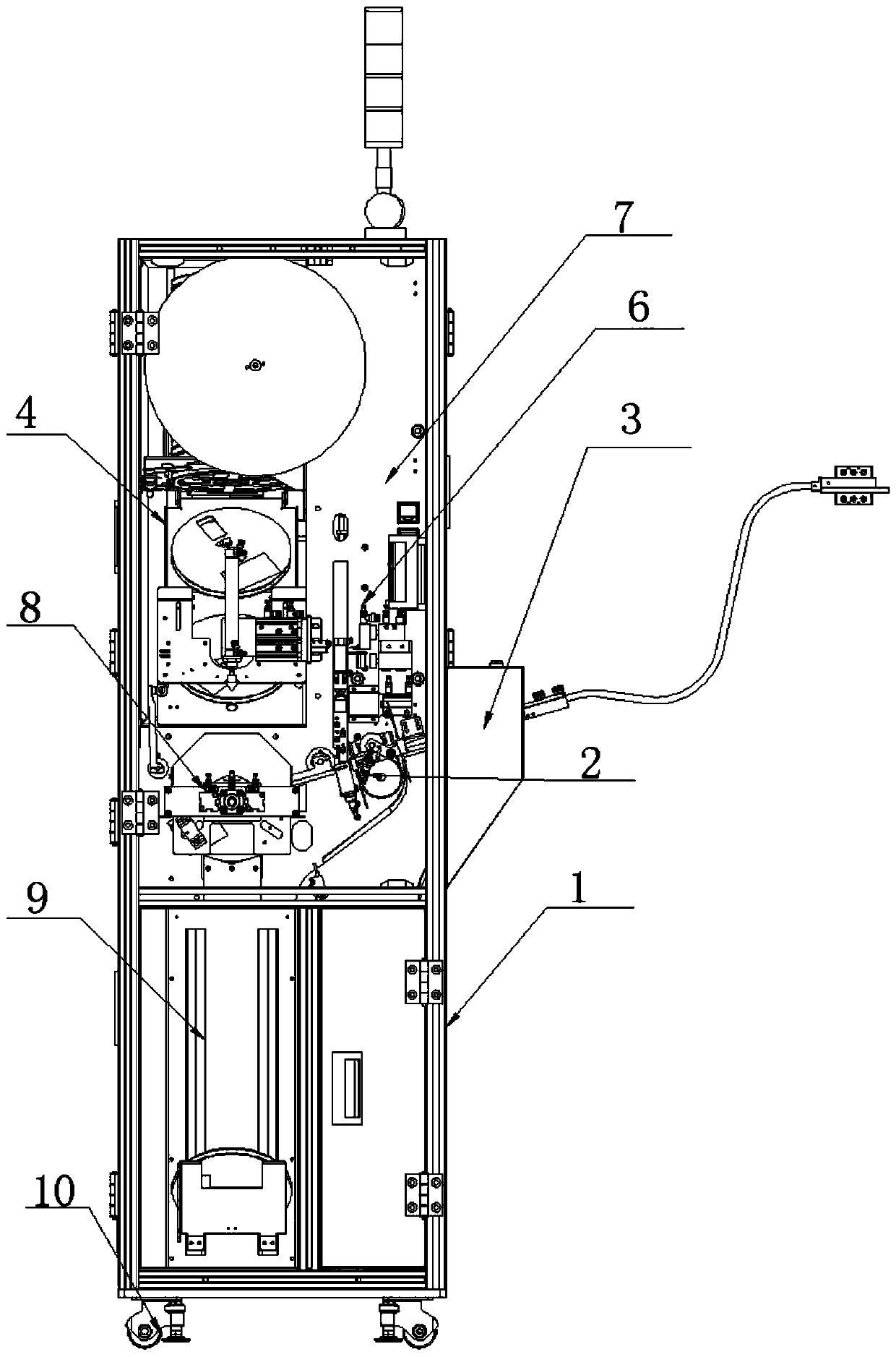

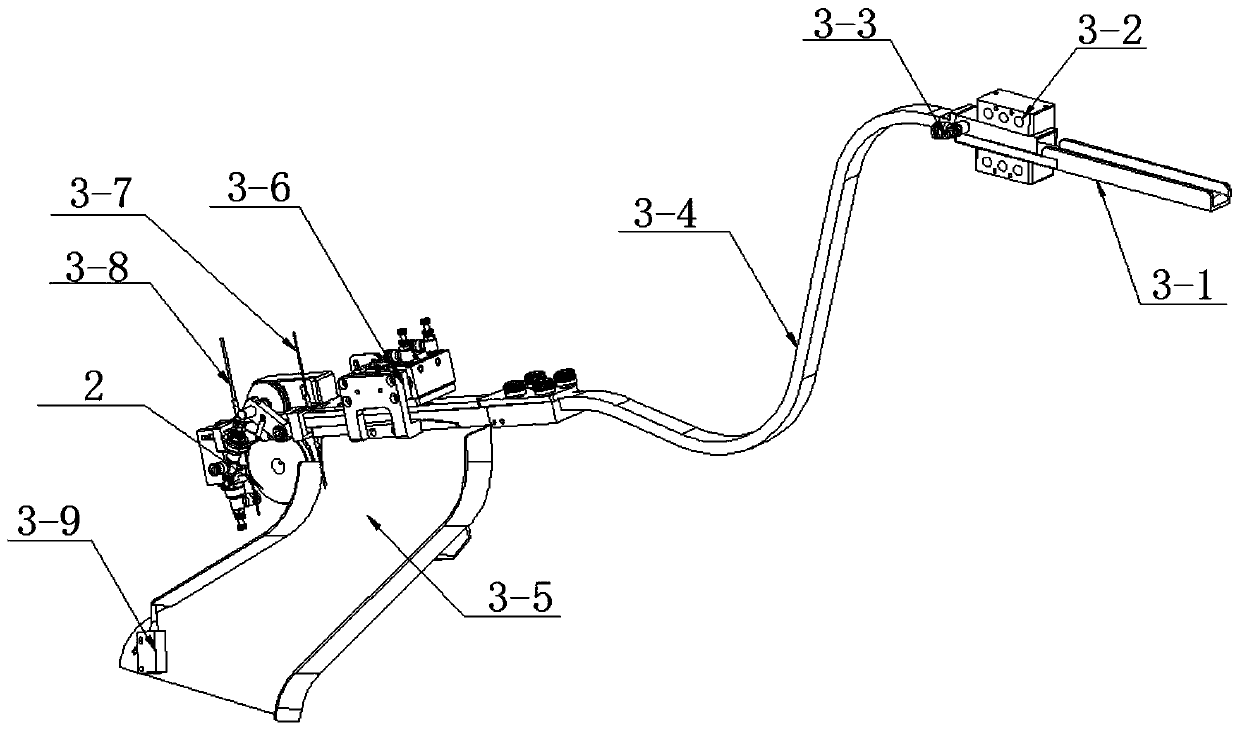

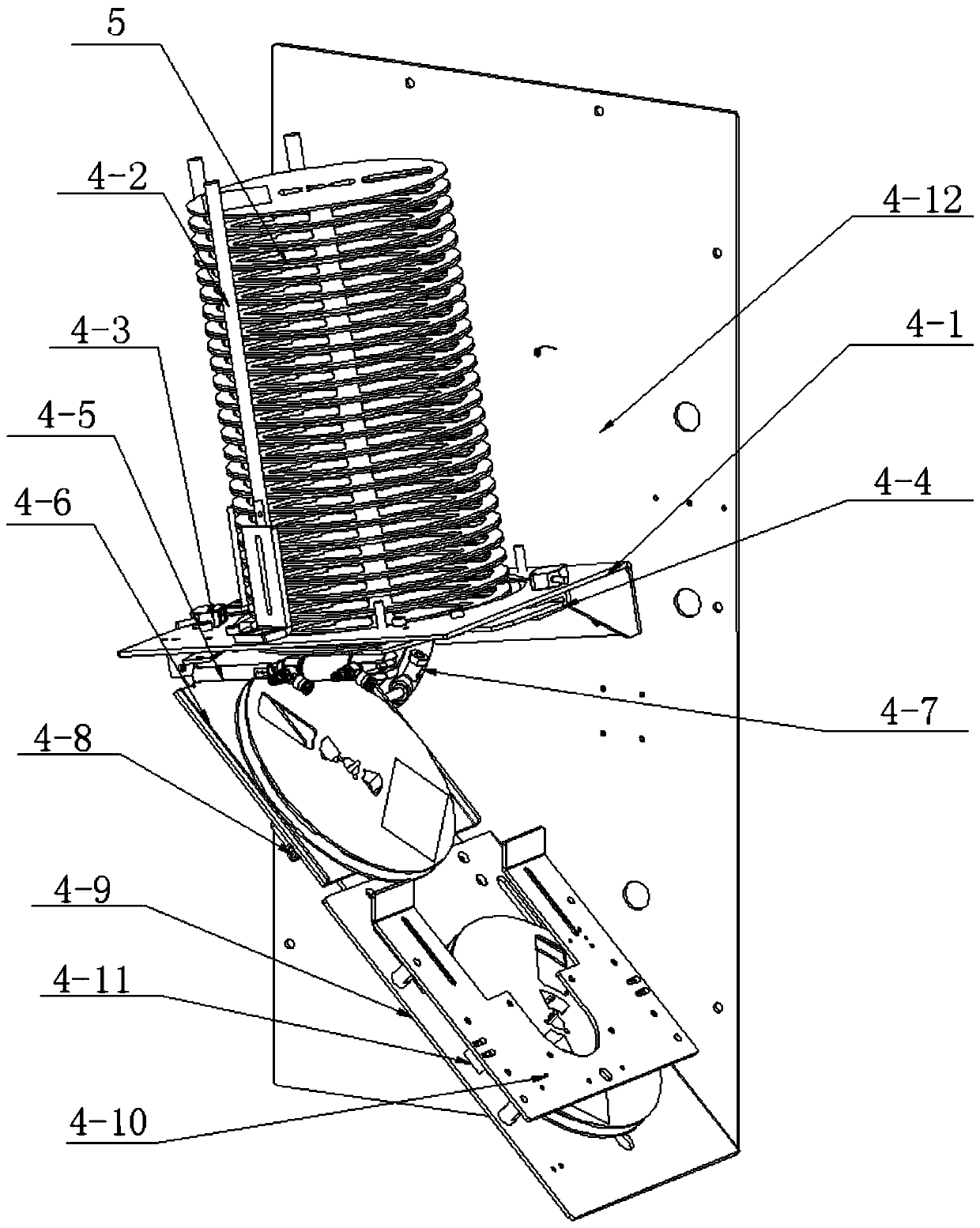

[0032] see as Figure 1-Figure 7 As shown, the technical solution adopted in this specific embodiment is: it includes a frame 1, a material storage mechanism 3, a tail glue mechanism 6, a material storage mechanism 4, a clamping mechanism 8 and a buffer mechanism 9; The side is provided with a material storage mechanism 4, and the frame 1 on the right side of the material storage mechanism 4 is provided with a tail glue mechanism 6, and the right side wall of the frame 1 is fixedly provided with a material storage mechanism 3, and the output of the material storage mechanism 3 The end is fixedly connected with a pin wheel guide mechanism 2, and the inside of the frame 1 on the left side of the pin wheel guide mechanism 2 is fixedly provided with a clamping mechanism 8, and the feeding end of the clamping mechanism 8 is connected to the discharge end of the storage mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com