Automatic tubular product packaging equipment

An automatic packaging and pipe technology, applied in the field of mechanical processing and manufacturing, can solve the problems of long production time, cumbersome packaging methods, unqualified pipe cutting size and sticking position, etc., achieve accurate cutting size and sticking position, and improve packaging efficiency. and yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, component structure, achieved purpose and effect of the present invention in detail, it will be described in detail below in conjunction with the accompanying drawings.

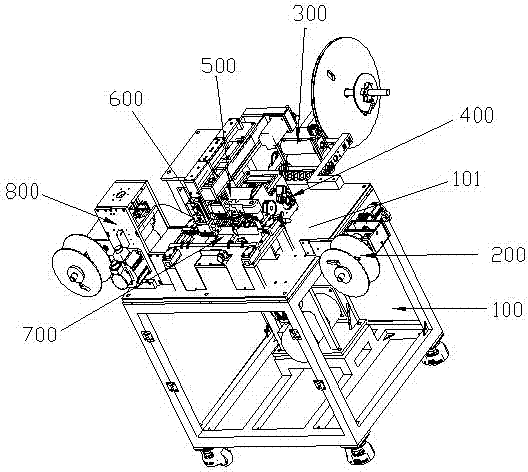

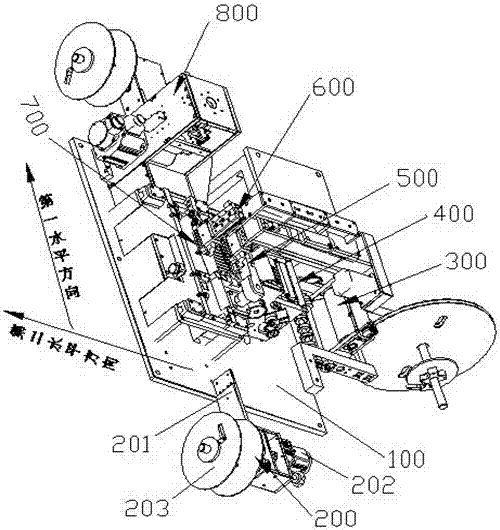

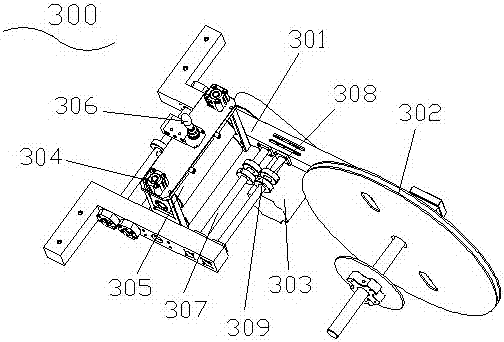

[0023] see Figure 1 to Figure 2 , an automatic packaging device for pipes in the present invention, comprising a frame 100, a tape mechanism 200, a pipe release mechanism 300, a pipe delivery mechanism 400, a cutter mechanism 500, a straw mechanism 600, a pipe sticking mechanism 700 and a winding mechanism 800, the The frame 100 has a horizontal fixing plate 101, the film tape mechanism 200, the tube sticking mechanism 700 and the winding mechanism 800 are fixed on the fixing plate along the first horizontal direction in turn, the tube releasing mechanism 300, the tube feeding mechanism 400 , the cutter mechanism 500, the straw mechanism 600 and the tube sticking mechanism 700 are sequentially fixed on the fixed plate along the second horizontal direction pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com