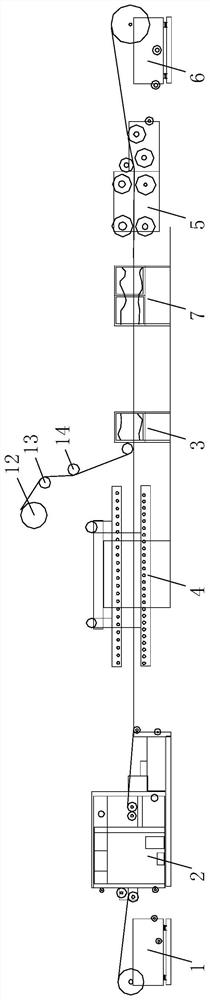

Hot paste composite slitting machine and hot paste composite slitting method thereof

A heat lamination and slitting machine technology, which is applied in metal processing and other directions, can solve the problems of low work efficiency, more equipment, and high production costs, and achieve the effects of reducing the occupied space of the factory building, accurate slitting size, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The present invention is a method for hot pasting compound cutting of a hot pasting compound slitting machine, including compounding and cutting; compounding includes the following steps:

[0068] S1. Pre-check;

[0069] S2. Set the tension setting value on the program panel according to the actual production roll diameter;

[0070] S3. When the temperature of the preheating and shaping oven rises to the set value, the operation starts;

[0071] S4. Install the prepared tube core with the corresponding width and thickness selected according to the production requirements on the rewinding inflatable shaft;

[0072] S5. Adjust the deviation correction position to keep the deviation correction position aligned with the edge of the tube core, and switch to the No. 1 or No. 2 winding position;

[0073] Slicing involves the following steps:

[0074] s1. Pre-check;

[0075] s2. Material preparation: According to the specifications required by the production plan, transfer ...

Embodiment 2

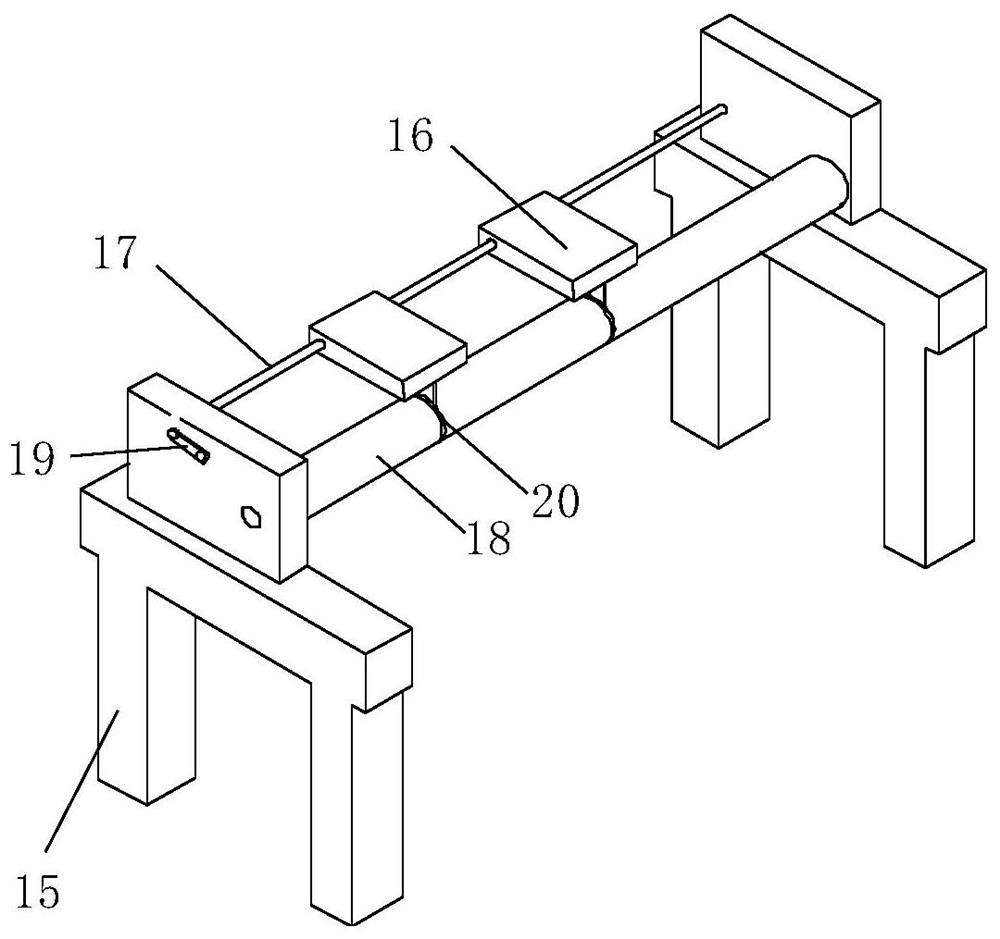

[0140] See Figure 4 , wherein, the slitting mechanism 5 includes a blade roller shaft 17 and a slitting guide roller 18 correspondingly arranged on the slitting frame 15 up and down; The cutting knife 16; the position corresponding to the cutting knife 16 on the slitting guide roller 18 is provided with a cutting knife groove 20 corresponding to the cutting knife 16 one by one;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com