Plate sawing equipment

A technology for sawing and plate cutting, applied in the field of plate sawing equipment, can solve the problems of sawing size error and cutting precision reduction, etc., and achieve the effects of accurate cutting saw size, improved sawing precision, and improved sawing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

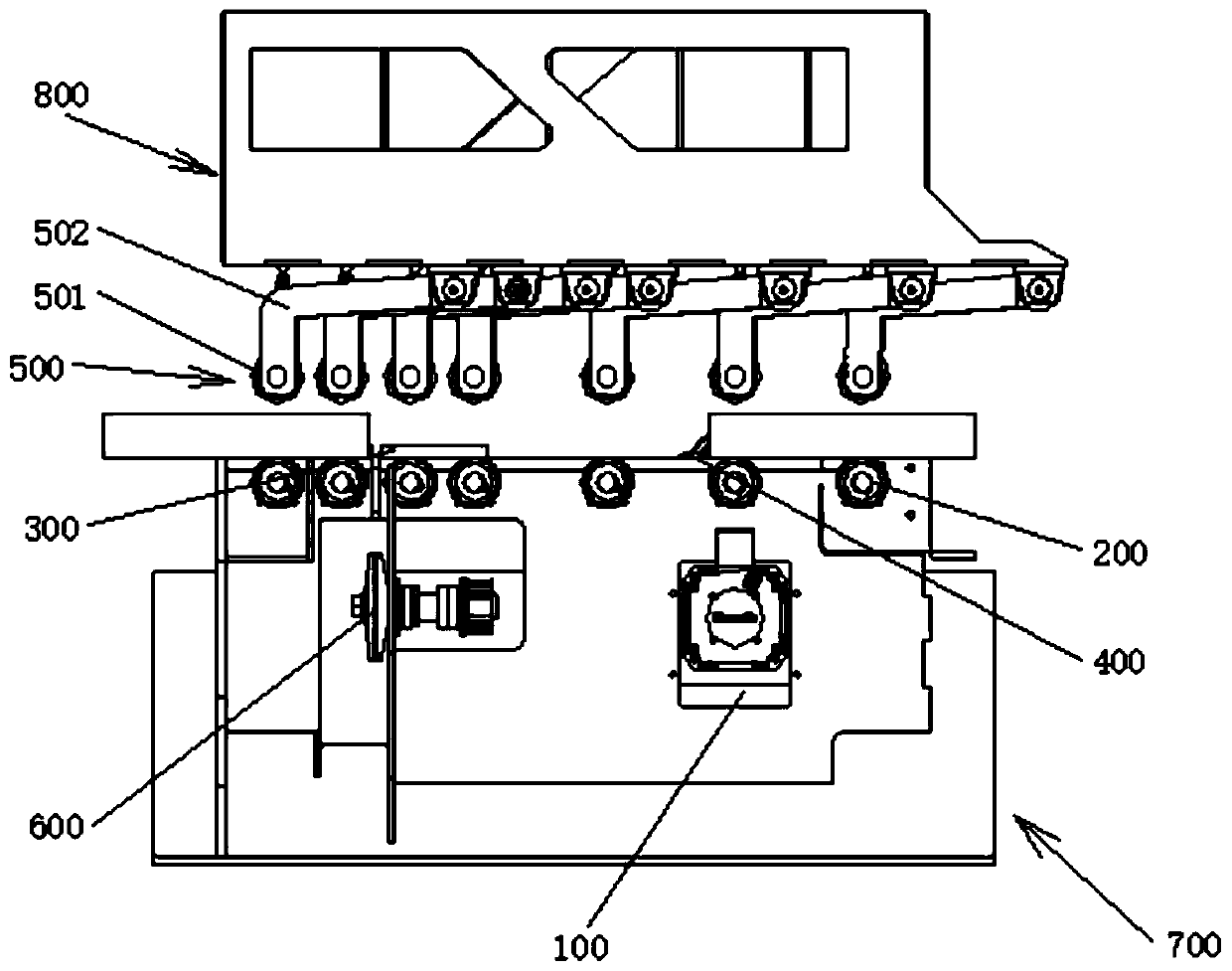

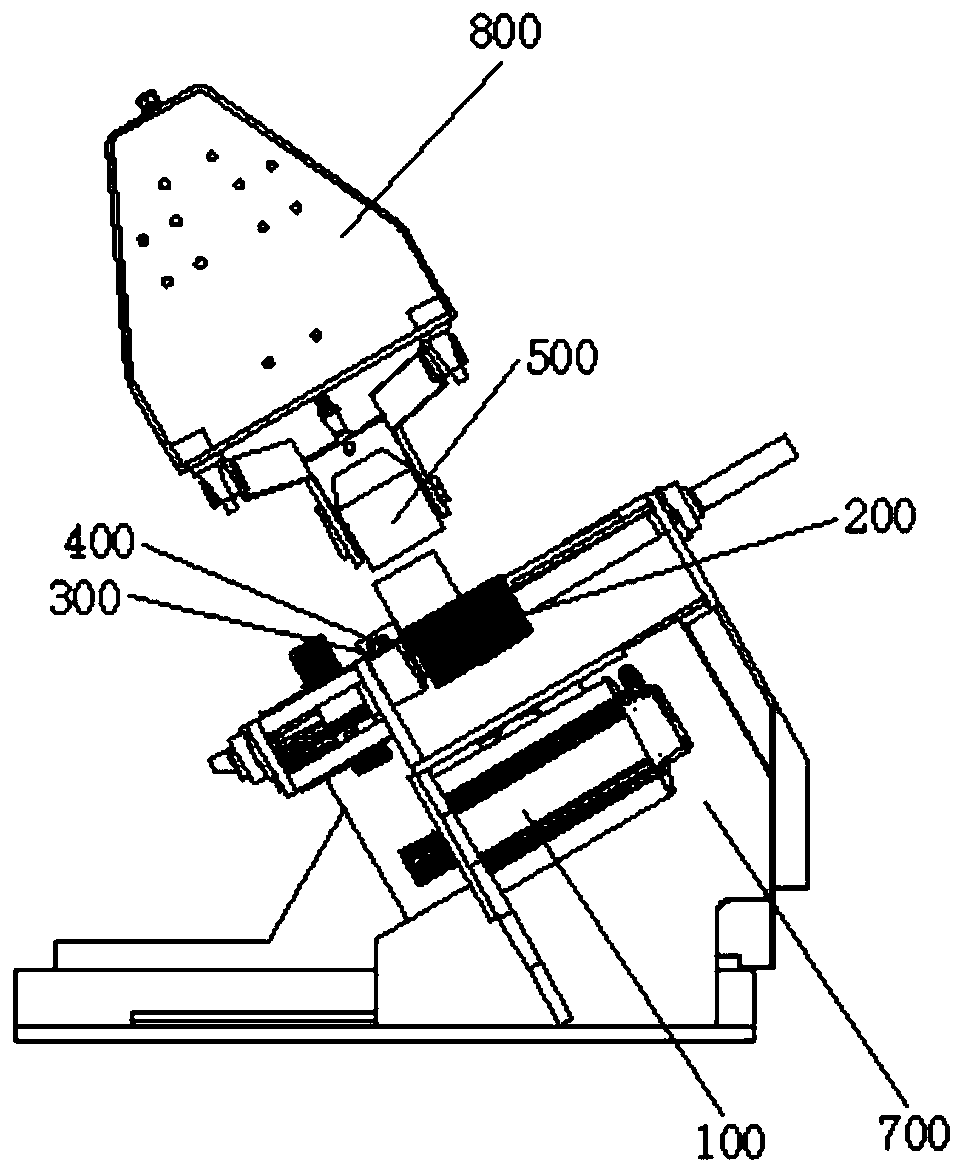

[0032] discussed below Figure 1 to Figure 2 , and the various embodiments used to describe the principles of the invention in this patent document are by way of illustration only and should not be construed as limiting the scope of the invention in any way. Those skilled in the art will appreciate that the principles of the present invention may be implemented in any suitable type of lumber sawing apparatus. The terminology used to describe various embodiments is exemplary. It should be understood that these are provided only to aid in the understanding of the description and that their use and definitions do not limit the scope of the invention in any way. The terms first, second, etc. are used to distinguish objects with the same set of terms and are not intended to imply temporal order in any way unless expressly stated otherwise. A group is defined as a non-empty group containing at least one element.

[0033] In order to make the purpose, technical solutions and advan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com