High-speed cutting all-in-one machine for producing steel

An all-in-one machine and cutting machine technology, which is applied in the direction of grinding racks, grinding machine parts, grinding machines, etc., can solve problems such as inability to achieve intelligence, achieve rapid cutting, reduce production time, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

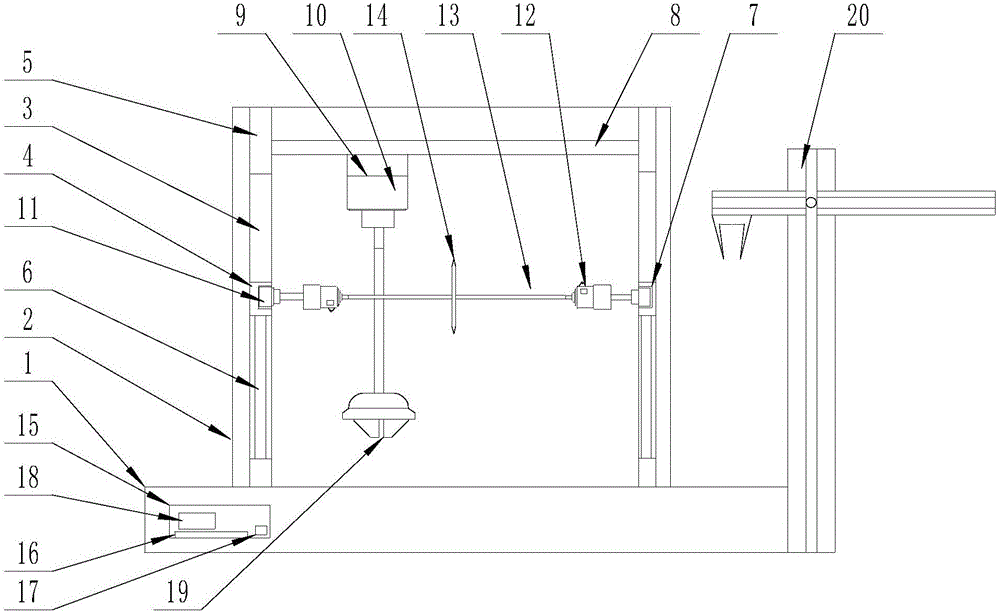

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a high-speed cutting integrated machine for steel production includes a base (1), a cutting mechanism is provided on the base (1), and the cutting machine mechanism is composed of a gantry fixedly installed on the base (1). Frame (2), a vertical opening (3) opened on the opposite side surface of the gantry frame (2) and along the length direction, a group of rectangular sliders (4) fixedly installed in the two vertical openings (3), fixedly installed Two sets of limit blocks (5) at the upper and lower ends of the two vertical openings (3), a set of electric push rods (6) fixedly installed on the inner lower surfaces of the two vertical openings (3), and a set of rectangular sliders (4) The circular groove (7) on the opposite outer surface, the slide rail (8) arranged on the gantry (2), the electric slider (9) fixedly installed in the slide rail, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com