Grabbing, correcting, positioning and shearing mechanism of automatic foot cutter

A foot cutting machine and automatic technology, which is applied in the field of cutting mechanism, correction, positioning and grasping, can solve the problems of low efficiency and inaccurate positioning, and achieve the effect of improving production efficiency, saving manpower and accurate cutting size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

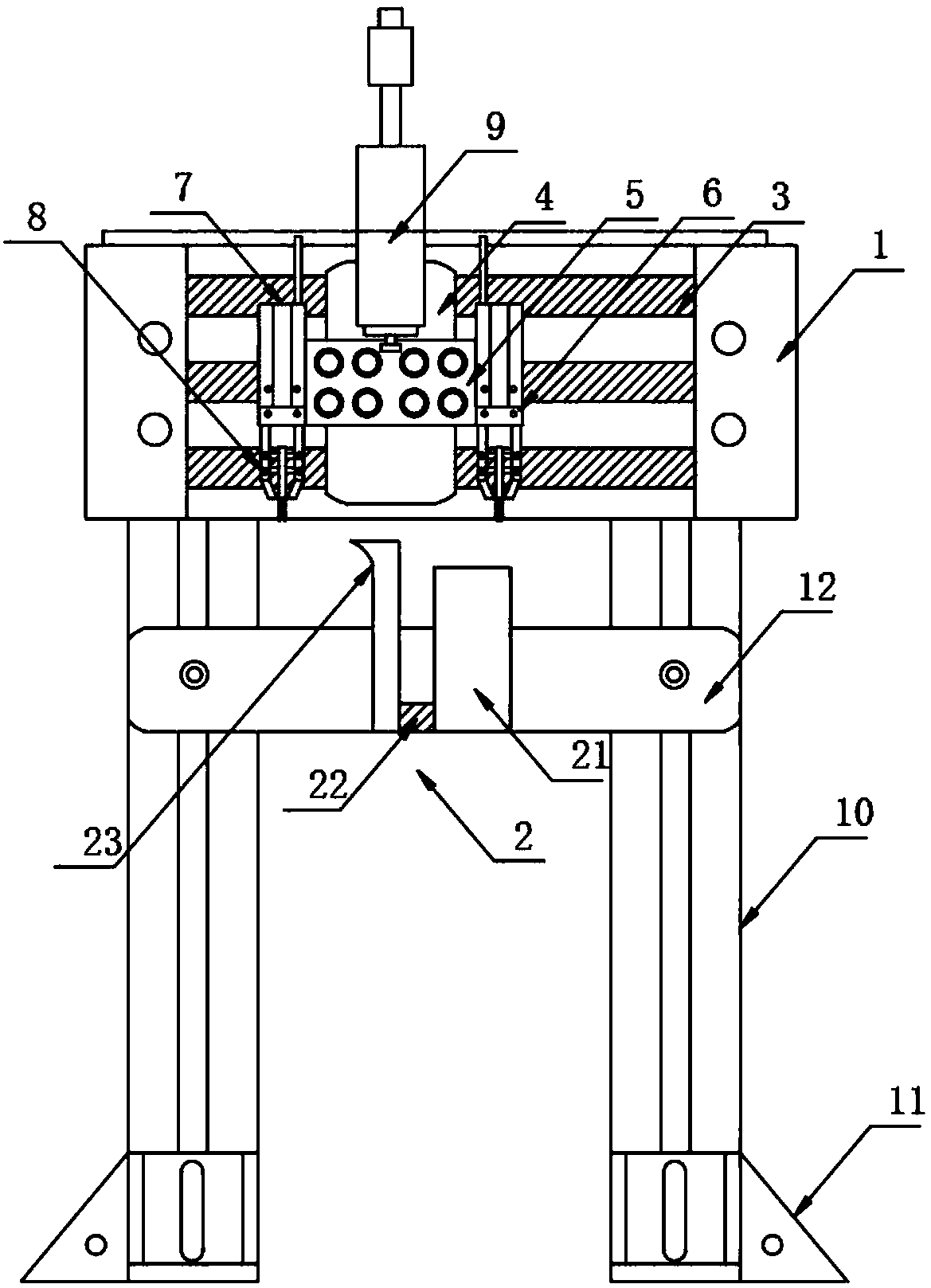

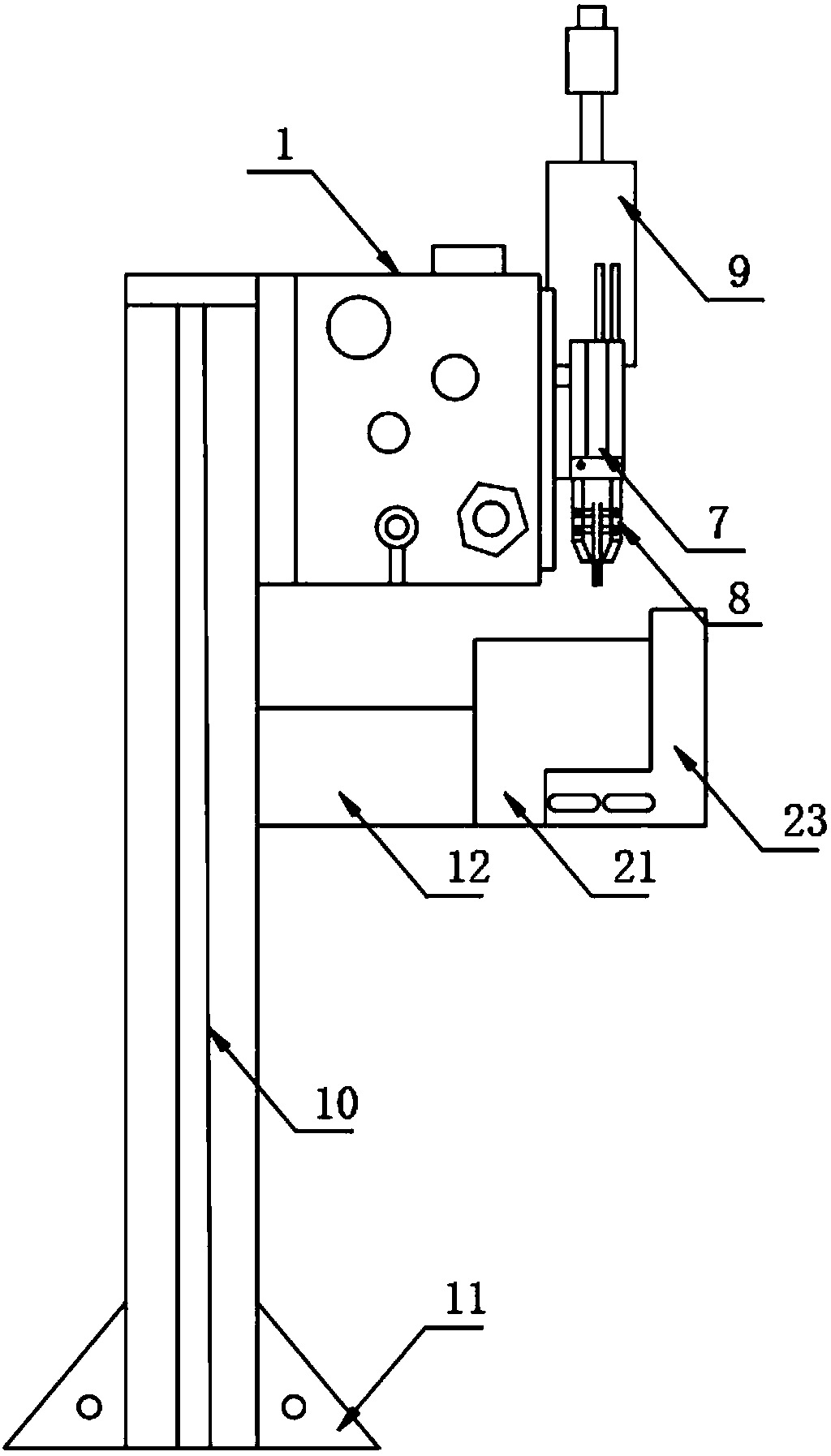

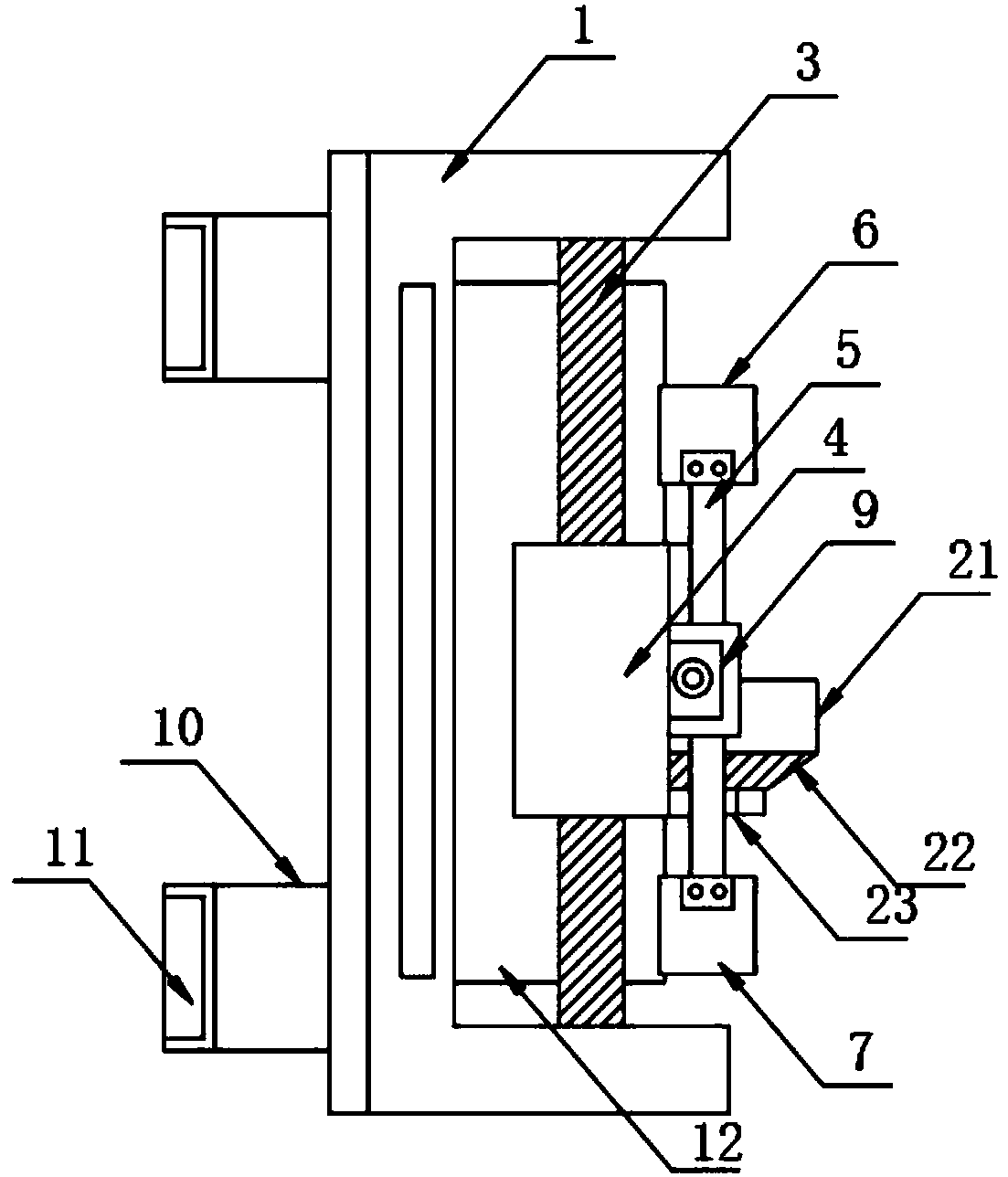

[0024] according to Figure 1-4 The grasping, correcting, positioning, and cutting mechanisms of a kind of automatic foot cutting machine shown include a rodless cylinder 1 and a cutting mechanism 2. The cutting mechanism 2 is arranged at the bottom end of the rodless cylinder 1, and the cutting mechanism 2 A cylinder rod 3 is provided, and a movable connecting plate 4 is arranged on the movable connecting plate 3. One end of the movable connecting plate 4 runs through the side wall of the rodless cylinder 1 and extends to one side of the outer wall of the rodless cylinder 1. The movable connecting plate 4 is movably connected on the rodless cylinder 1, a fixed frame 5 is arranged on one side of the outer wall of the movable connecting plate 4, and a first finger cylinder 6 and a second finger cylinder 6 and a second finger are fixedly arranged at both ends of the fixed frame 5 respectively. Cylinder 7, the bottom of the first finger cylinder 6 and the second finger cylinder 7...

Embodiment 2

[0028] The difference with embodiment 1 is:

[0029] The cutting mechanism 2 includes a baffle plate 21, a moving and cutting fixed plate 22 and a correction block 23, the moving and cutting fixed plate 22 is fixedly arranged on the bottom of one side of the baffle plate 21, and the correction block 23 is fixedly arranged on the moving and cutting shear The other end of the fixed plate 22, and the top of the correction block 23 is higher than the baffle plate 21. Through the correction block 23 in the cutting mechanism 2, the objects placed on the cutting mechanism 2 are corrected and limited, so as to avoid the , the object slides on the 2 cutting mechanism 2, thereby affecting the cutting size of the object;

[0030] One side of the movable connecting plate 4 is fixedly provided with a cutter cylinder 9, and the cutter cylinder 9 is arranged on one side of the top of the fixed frame 5, and the output end of the cutter cylinder 9 is provided with a cutter, which passes throug...

Embodiment 3

[0034] The difference with embodiment 1 and embodiment 2 is:

[0035] The top of the rodless cylinder 1 is provided with a controller, and the first finger cylinder 6, the second finger cylinder 7, the air claw 8 and the cutter cylinder 9 are all electrically connected to an external power supply through the controller, and the external power supply is set For 220V municipal power supply;

[0036] The controller is provided with a start button 12 and an emergency stop button 13 for connecting the external power supply, a rodless cylinder operation button 14 for controlling the operation of the rodless cylinder 1, and a button for controlling the first finger cylinder 6 up and down. The first finger cylinder movement button 15, is provided with the second finger cylinder button 16 that is used to control the second finger cylinder 7 up and down, is provided with the air claw operation button 17 that is used to control the air claw 8 to open and is provided with for controlling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com