Production technology of small weighing sensor

A weighing sensor and production process technology, applied in the direction of weighing equipment, instruments, weighing, etc. that use elastically deformable parts, can solve the problem of low sensor sensitivity, microscopic unevenness on the surface of the patch area, and difficulty in reusing cleaning agents, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

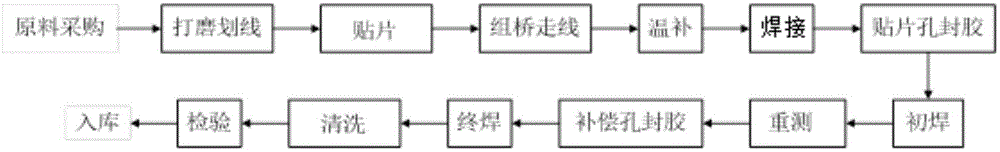

[0017] A production process of a small weighing sensor, including grinding and scribing, patching, bridge wiring, warming, welding, patch hole sealing, initial welding, retesting, compensation hole sealing, final welding, cleaning, Warehouse inspection, packaging and other processes, grinding off the processing lines and electroplating layer on the elastic body, activating the metal surface, marking the baseline when patching, pasting the sensitive element on the elastic element, connecting the strain gauge, and performing the temperature compensation process , solder the wires to the circuit board, seal the sensor patch hole and the compensation hole, isolate the outside world, form an independent internal climate environment, weld the wires to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com