Laser printer developing device sealing sheet adhesion device

A technology of laser printer and developing device, which is applied to optics, electric recording process applying charge pattern, equipment applying electric recording process of electric charge pattern, etc. problems such as stability, product quality instability, and low efficiency, to achieve the effect of improving paste efficiency, improving labor safety, and sticking firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

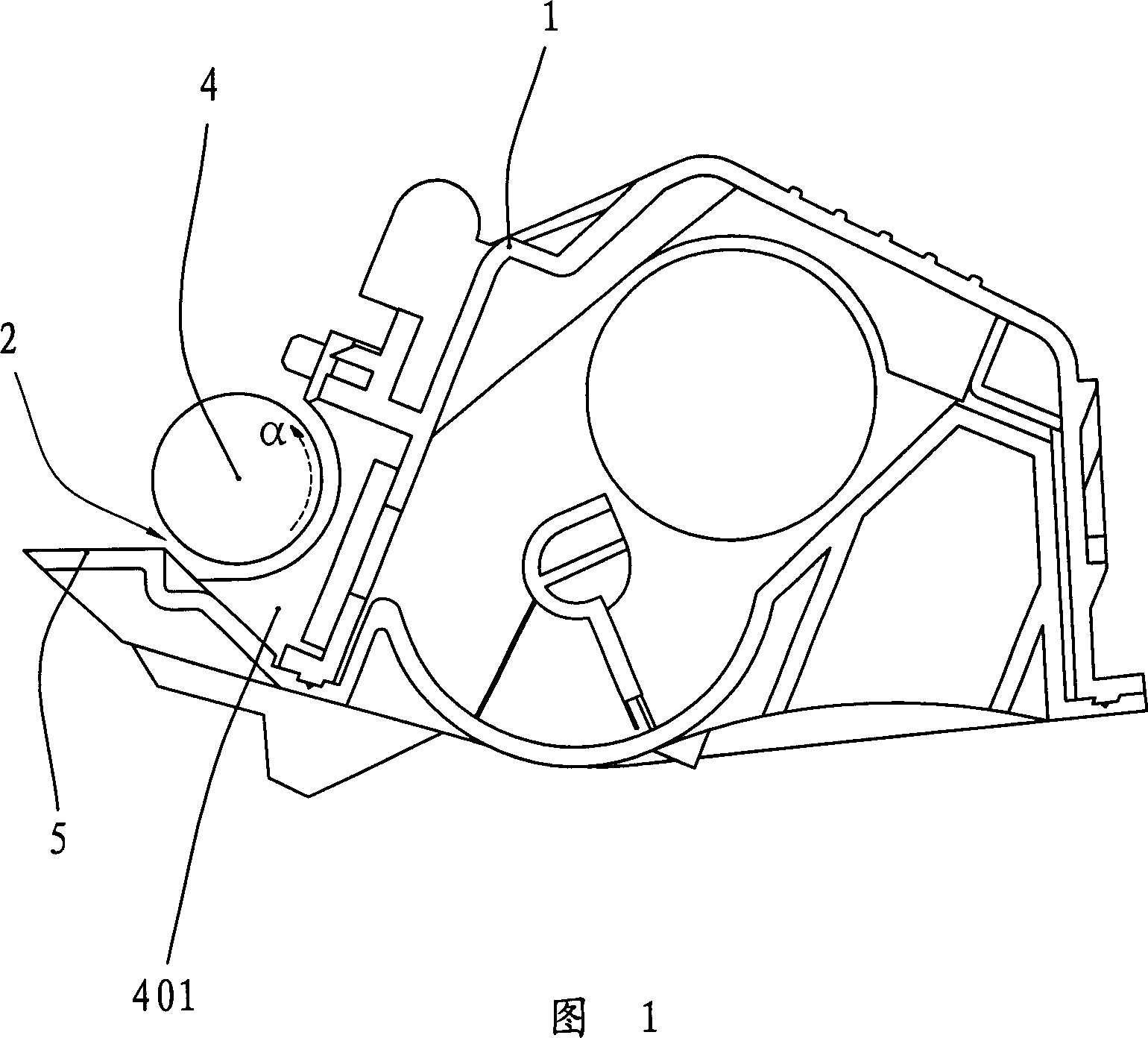

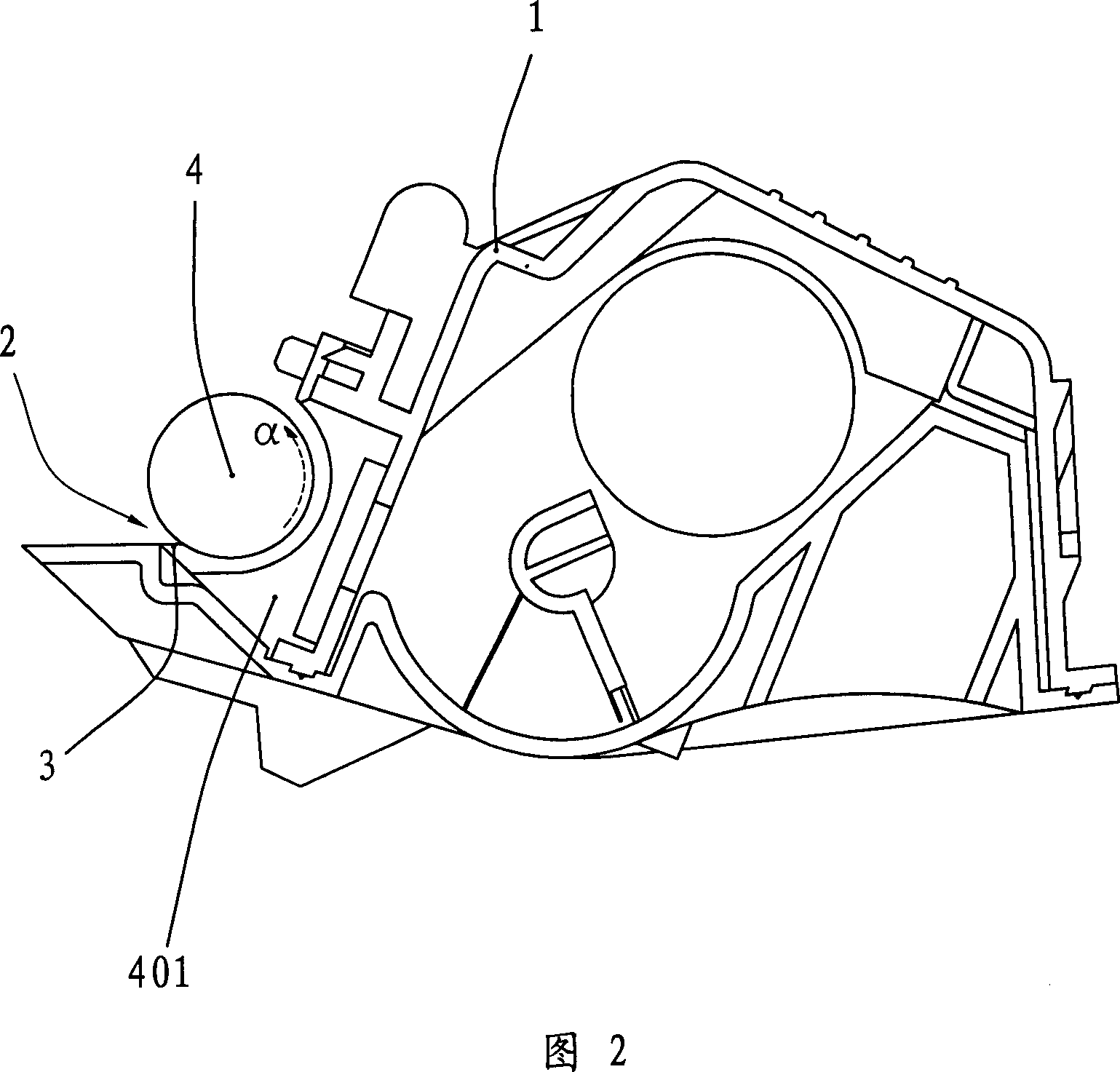

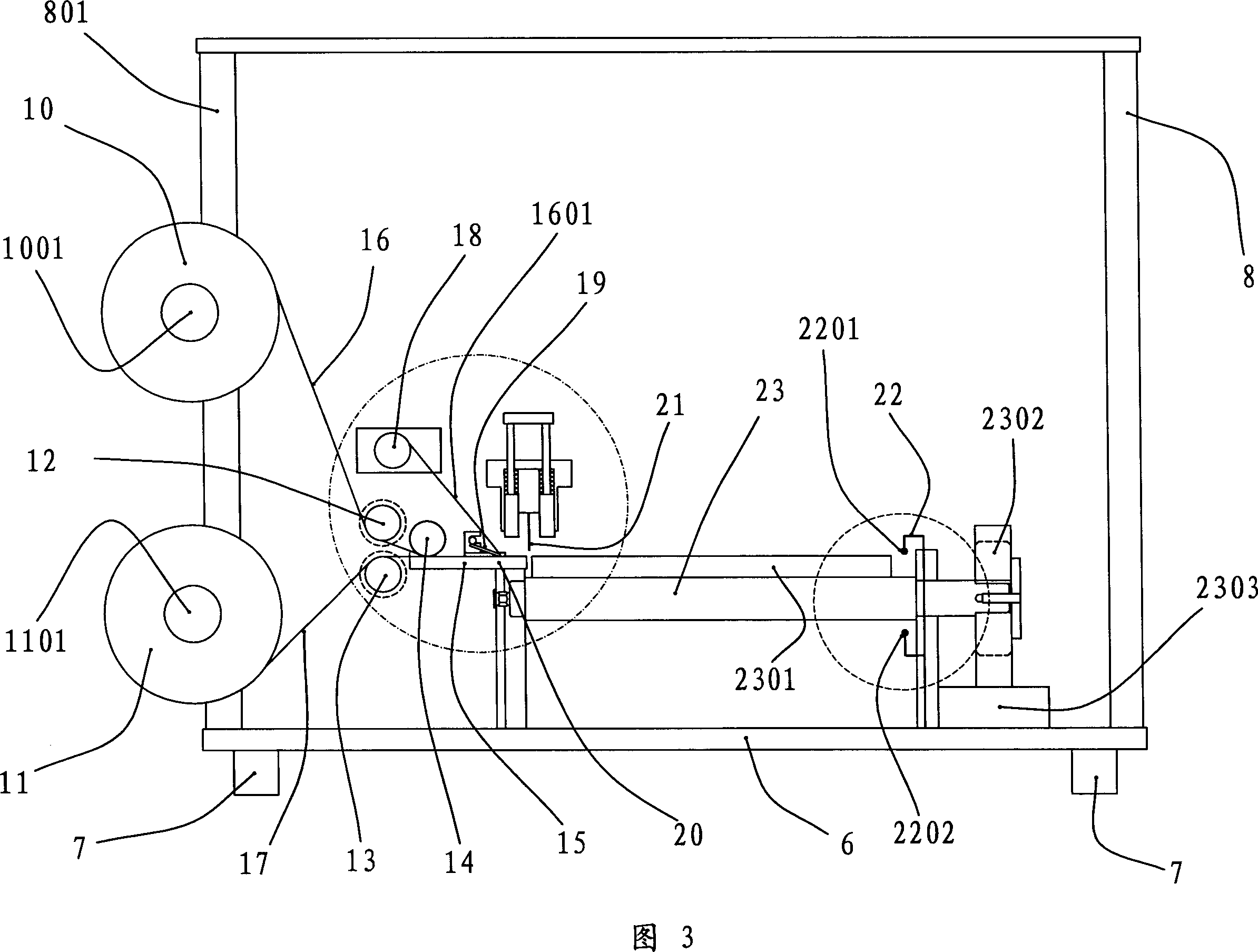

[0039] Referring to Figures 3, 4, and 5, the schematic diagrams of the corresponding planar structures of the bonding device for the sealing sheet used in the developing device of the laser printer. In the figure, the placement state of the sticking device is the same as that in actual application.

[0040] The pasting device includes five basic components: a base A, a sealing sheet bonding mechanism B, a paper glue separating mechanism C, a sealing sheet cutting mechanism D, a sealing sheet pasting mechanism E and a programmable controller f.

[0041] See Figures 3 and 4, the base A structurally includes a seat plate 6, an angle frame 7 and a chassis 8. Its seat plate 6 is supported on the corner frame 7 in a manner parallel to the horizontal plane. The bottom of the cabinet 8 is fixedly supported around the upper surface of the seat plate 6 . An installation platform 9 for accommodating or placing the developing device 1 is provided on the upper surface of the seat plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com