Batch strain gauge pasting method

A strain gauge, batch technology, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of difficulty in pasting strain gages, inability to use test pieces, etc., achieving high repeatability, high pasting efficiency, and reducing mutual interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment -1

[0049] The method for pasting the above-mentioned strain gauges in batches includes the following steps:

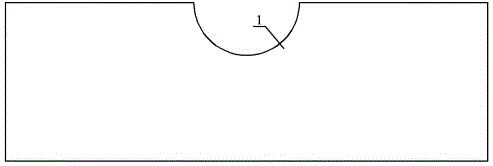

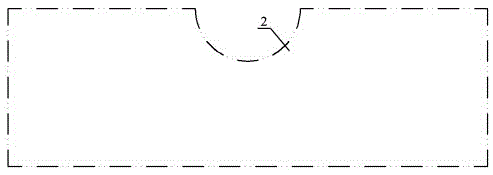

[0050] 1) Measure the external dimensions of the notched sample 1 and use CAD (for example, AutoCAD) software to draw the external profile of the notched sample according to the measured dimensions figure 2 .

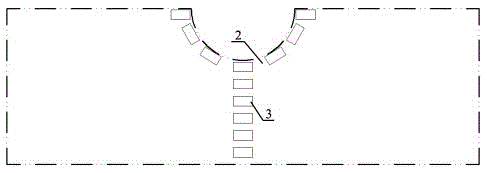

[0051] 2) According to the sticking requirements of the notched specimen strain gauge 6 of the notched specimen 1 (strain gauge position, spacing, angle, etc.), in the above CAD drawing ( figure 2 ) to mark the sticking position of the notched sample strain gauge 6 with the notched sample strain gauge position marking frame 3 having the same base size as the notched sample strain gauge 6 .

[0052] 3) Outline of the notched specimen figure 2 Draw the location mark point 5 on the outline of the notched sample, and draw the location mark point 4 on the surface of the notch sample 1 .

[0053] 4) Take the profile diagram of the notched sample obtained in step 3)...

specific Embodiment -2

[0061] The method for pasting the above-mentioned strain gauges in batches includes the following steps:

[0062] 1) Use CAD (for example, AutoCAD) software to draw the outline of the gear sample according to the design dimensions of the gear sample 7 Figure 8 .

[0063] 2) According to the sticking requirements of the gear sample strain gauge 12 of the gear sample 7 (strain gauge position, spacing, angle, etc.), in the above CAD drawing ( Figure 9 ) to mark the sticking position of the gear sample strain gauge 12 with the gear sample strain gauge position marking frame 9 having the same base size as the gear sample strain gauge 12 .

[0064] (3) Outline of the gear sample Figure 8 Draw the gear sample outline position positioning mark point 11 on the upper surface, and draw the gear sample position positioning mark point 10 on the gear sample 7 surface.

[0065] 4) Take the profile diagram of the gear sample obtained in step 3) ( Figure 12 ) at a ratio of 1:1 on trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com