Adhesive tape pasting device

A tape and tape wheel technology, applied in the directions of sending objects, thin material handling, transportation and packaging, can solve the problems that affect the bonding effect of tape, the tape is not smooth, and the adhesive tape is unequal, so as to improve the efficiency and utilization of the adhesive tape, Simple and fast operation, sticky surface cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following, the present invention will be described in detail and completely through specific embodiments in conjunction with the accompanying drawings.

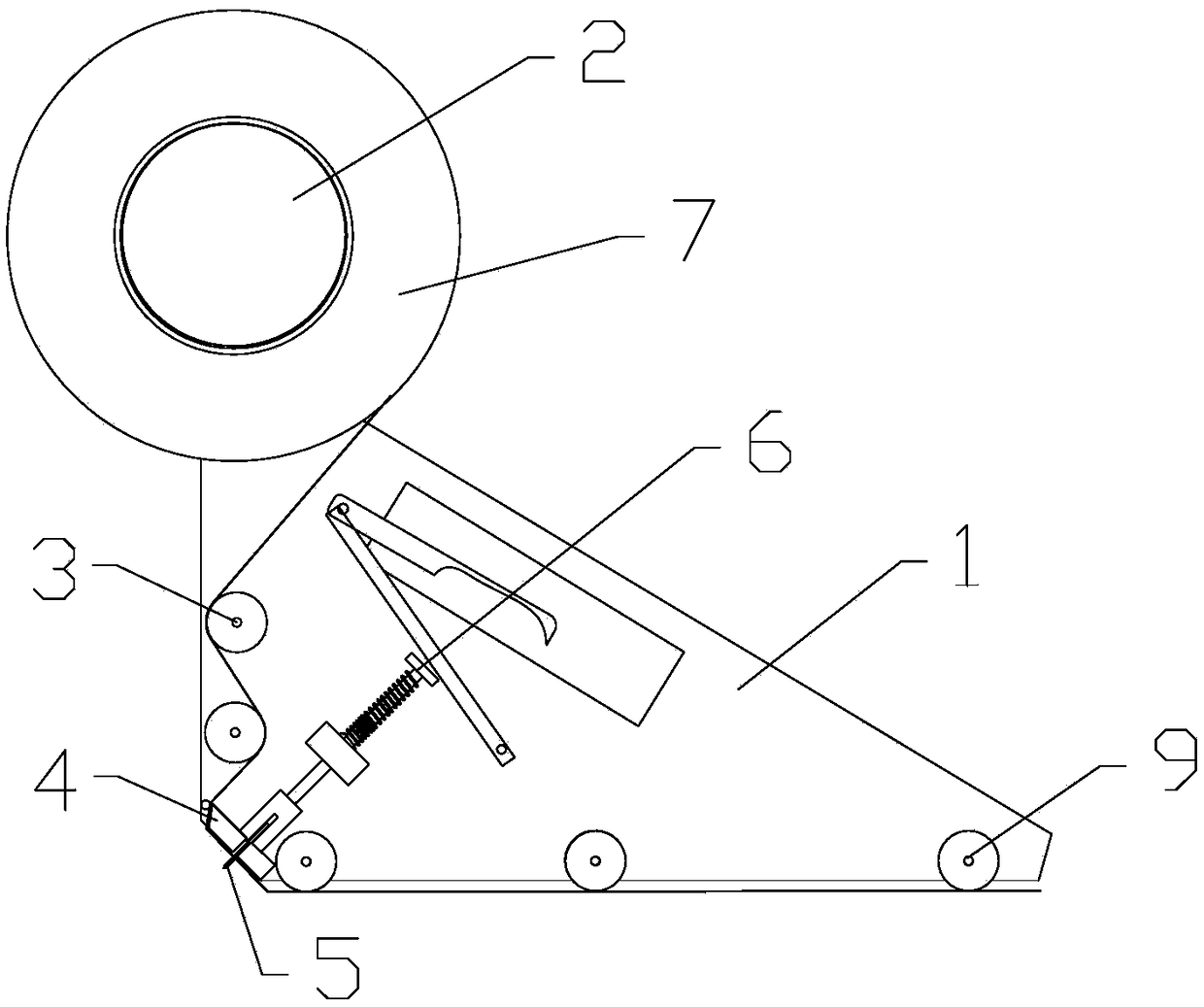

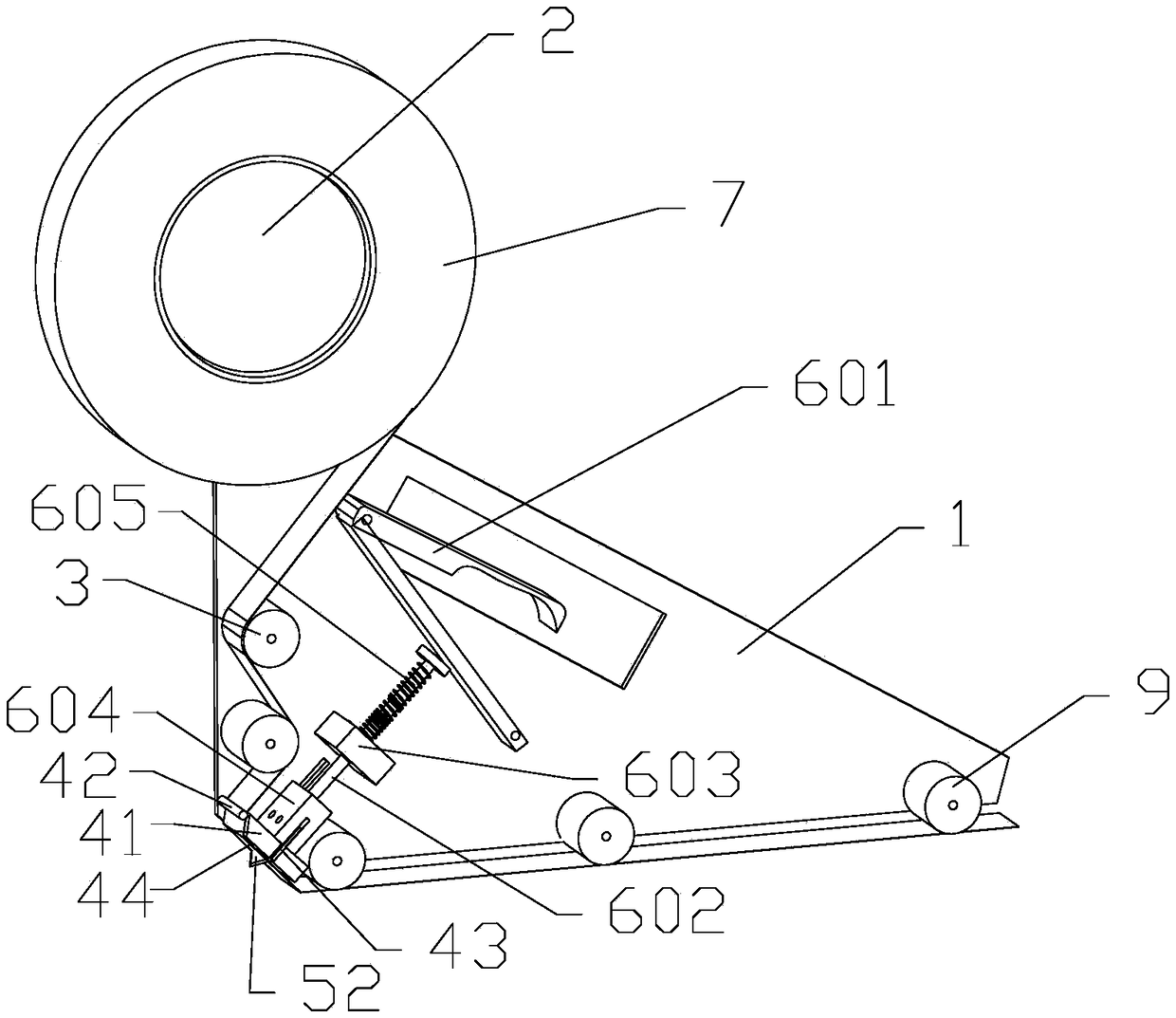

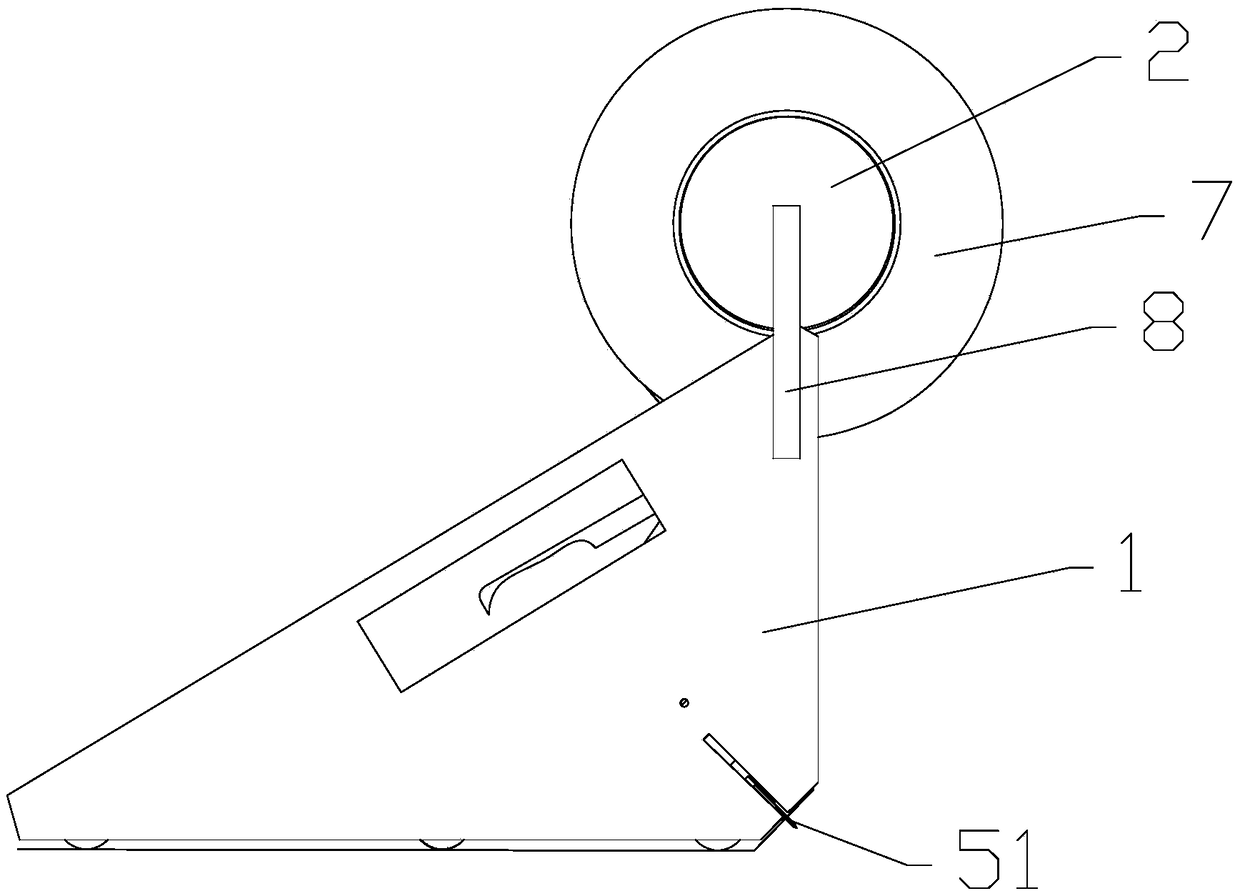

[0030] Please refer to Figure 1-3 As shown, the present invention provides a tape applicator, comprising a bracket 1, a tape wheel 2, several transmission wheels 3, a cutting platform 4, a cutting mechanism 5 and a control mechanism 6, and the tape wheel 2 is arranged on the support 1 for placing Adhesive tape 7; transmission wheel 3 is rotatably arranged on the bracket 1, and is used to transfer the adhesive tape 7 on the tape wheel 2 to the cutting platform 4; the cutting platform 4 includes a belt pressing table 41 and a traction roller 42, and the belt pressing table 41 is located on the support 1 is used to press the free end of the adhesive tape 7 for pasting, and the traction roller 42 is arranged on one side of the belt pressing table 41 and cooperates with the belt pressing table 41 to guide the free e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com