Test tube bar code pasting machine

A sticking machine and test tube technology, which is applied in the field of barcode sticking devices, can solve the problems of low feeding efficiency, inability to print and paste continuously automatically, etc., and achieve the effects of improved clamping efficiency, high sticking efficiency, and high clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

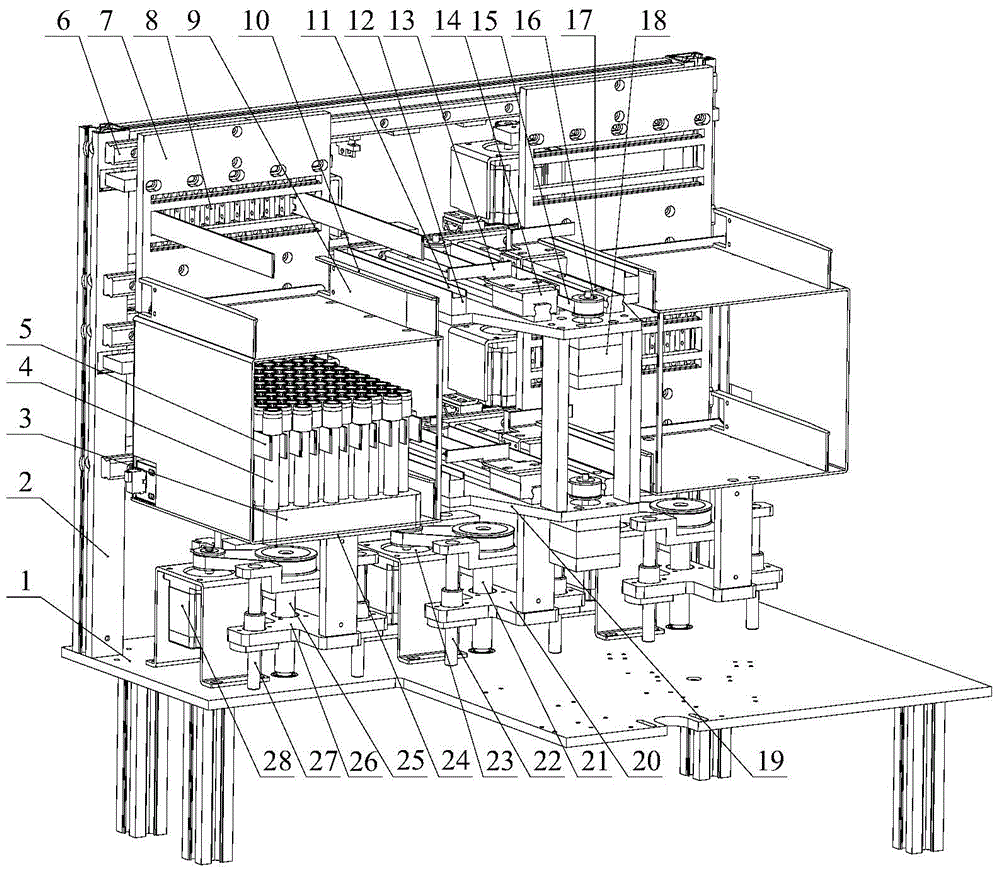

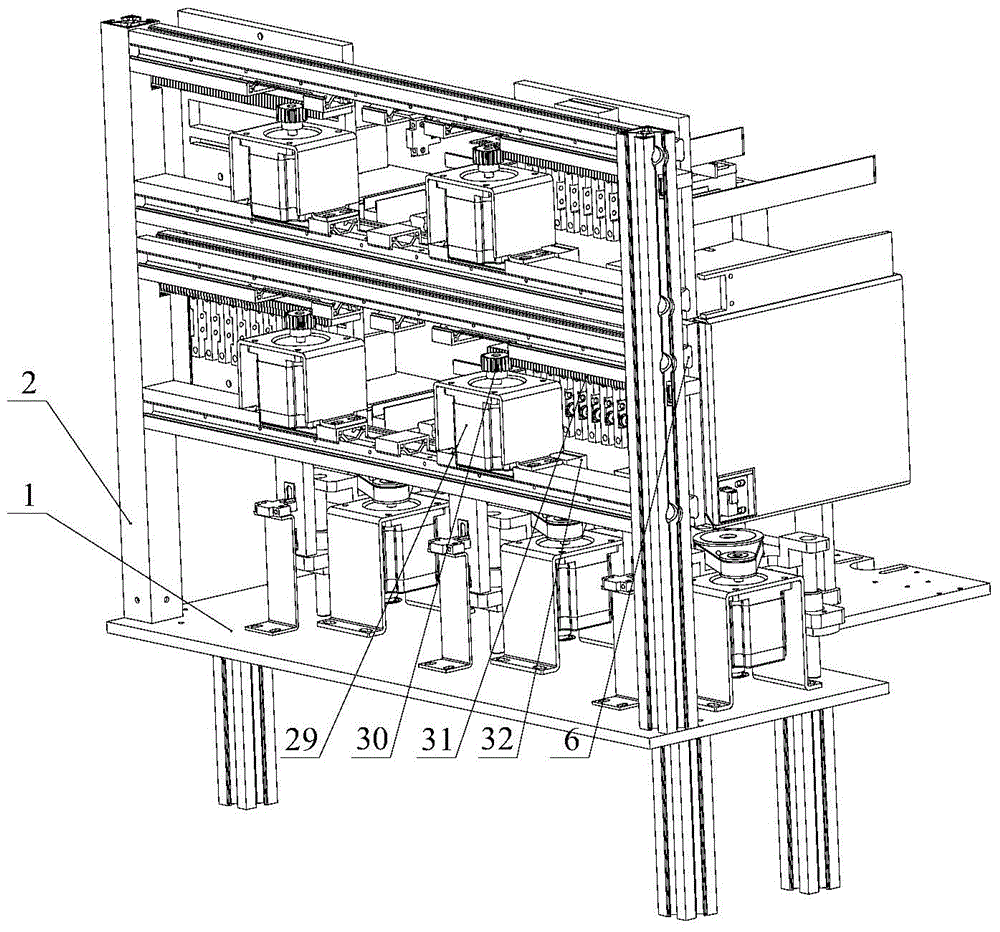

[0095] Below in conjunction with each accompanying drawing, the present invention is described in detail.

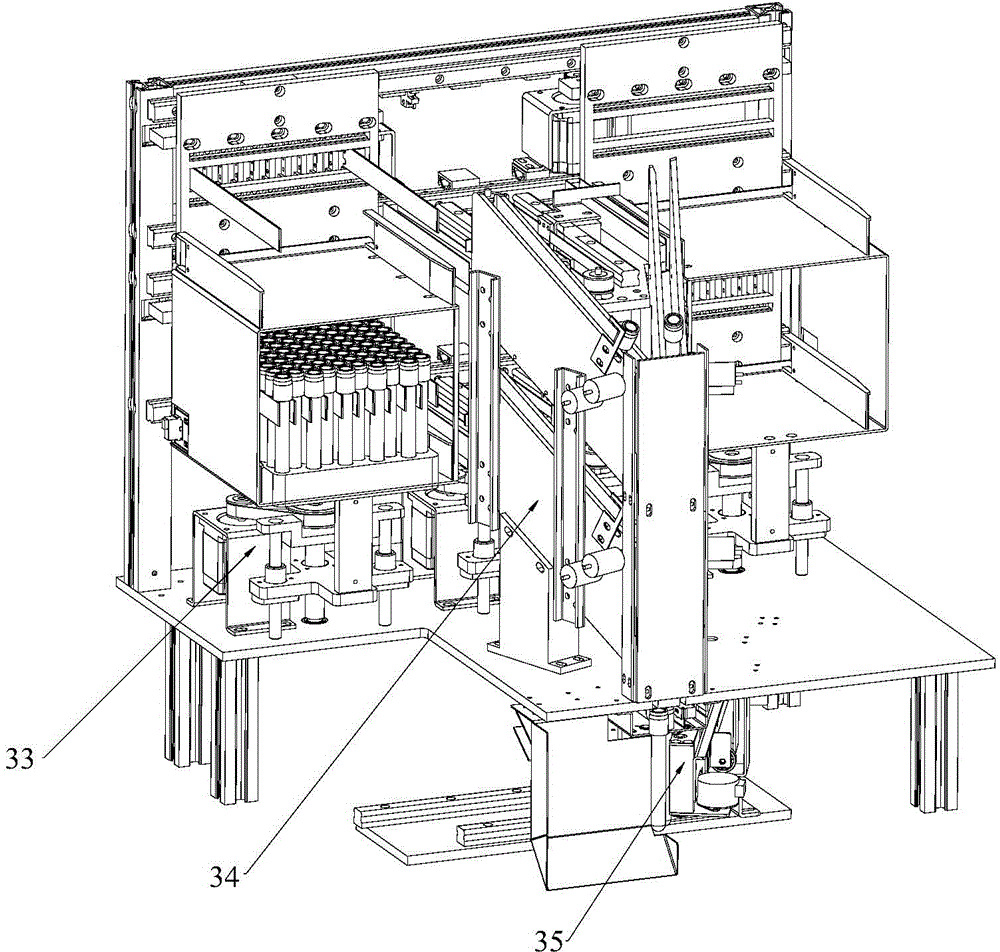

[0096] Such as figure 1 As shown, a test tube barcode pasting machine is used to paste the barcode on the test tube 4. The test tube barcode pasting machine includes a frame body, the frame body includes a bottom plate 1 and a bracket 2 erected on the bottom plate, and a feeding system is arranged on the frame body 33. The conveying mechanism 34 and the pasting system 35.

[0097] Feed system 33 includes:

[0098] Test tube clamping mechanism for clamping test tubes;

[0099] A disengagement mechanism, used to disengage the test tube 4 and the test tube foam seat 3 from each other;

[0100] The transmission mechanism is used to drive the test tube clamping mechanism to the designated position;

[0101] The jacking mechanism is used to jack up the test tube on the test tube clamping mechanism;

[0102] The pushing mechanism is used to push the test tube lifted by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com