Method and system for pasting electronic tags at high speed

An electronic label, high-speed technology, applied in the direction of labels, labeling machines, transportation and packaging, etc., can solve the problems of forming packages, unable to paste electronic labels at high speed, and unable to paste target objects, etc., to improve processing speed, overcome rhythm and Discrete, small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

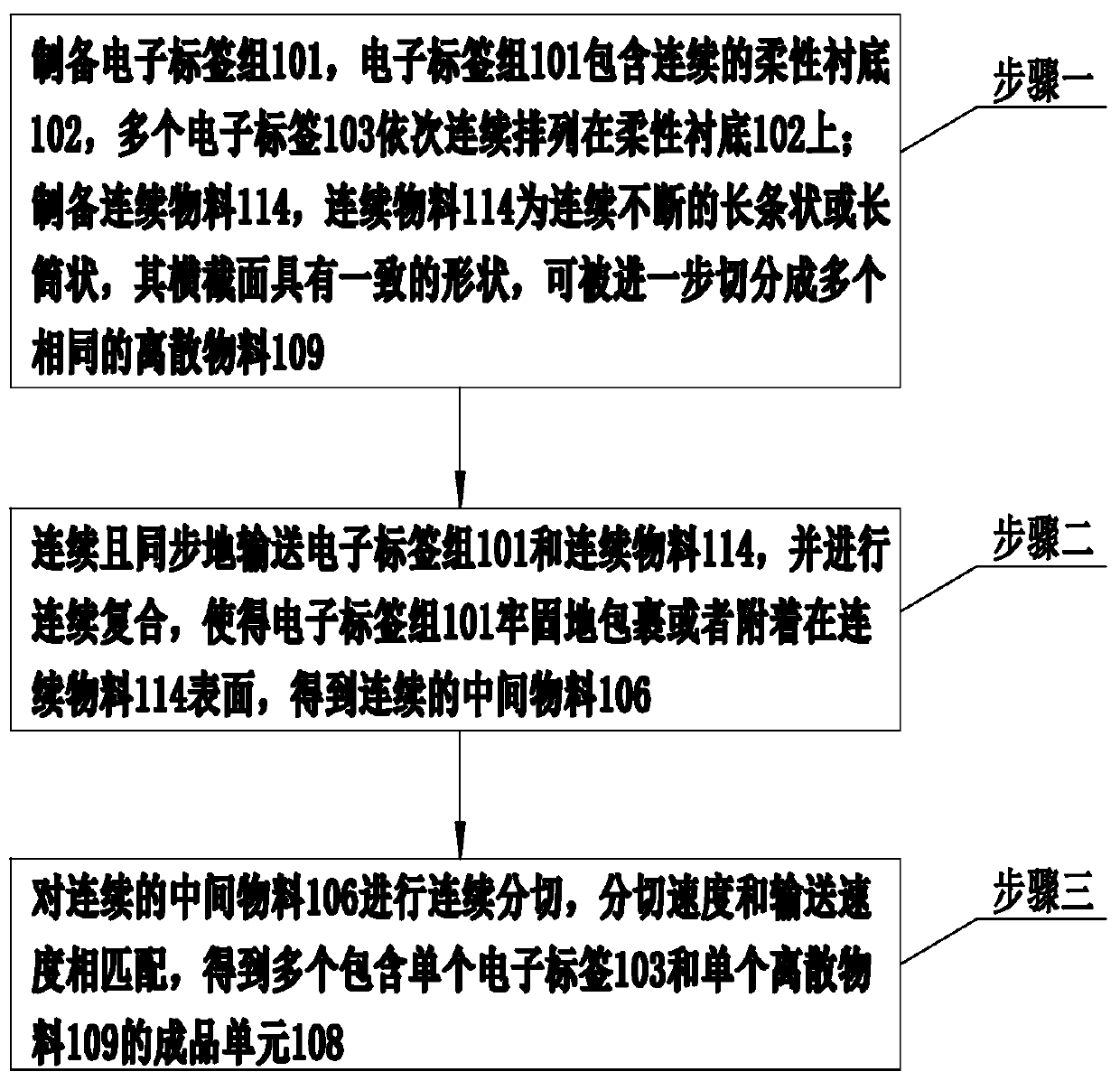

[0035] Specific implementation mode one: as Figure 1-Figure 7 As shown, this embodiment discloses a method for realizing high-speed pasting of electronic labels, including:

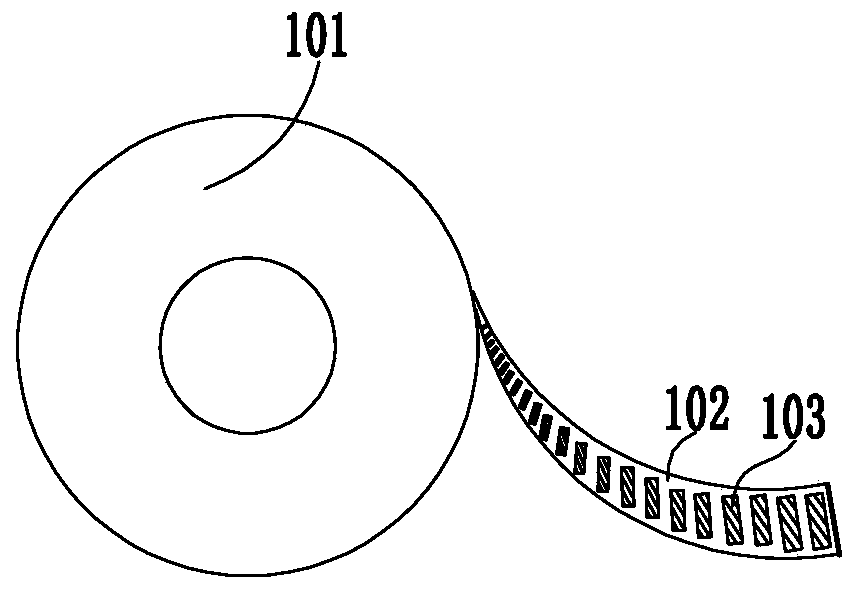

[0036] Step 1: Prepare an electronic tag group 101, the electronic tag group 101 includes a continuous flexible substrate 102, and a plurality of electronic tags 103 are sequentially and continuously arranged on the flexible substrate 102; prepare a continuous material 114, and the continuous material 114 is a continuous strip shape or long tube, its cross-section has a consistent shape, and can be further cut into a plurality of identical discrete materials 109;

[0037] Step 2: Continuously and synchronously conveying the electronic label group 101 and the continuous material 114, and performing continuous compounding, so that the electronic label group 101 is firmly wrapped or attached to the surface of the continuous material 114 to obtain a continuous intermediate material 106;

[0038] Step 3: Car...

specific Embodiment approach 2

[0043] Specific implementation mode two: as figure 2 , Figure 4 , Figure 7-Figure 9 , Figure 13 As shown, this embodiment discloses a system for realizing high-speed pasting of electronic labels, including:

[0044] An electronic tag group 101, the electronic tag group 101 includes a continuous flexible substrate 102, and a plurality of electronic tags 103 are sequentially and continuously arranged on the flexible substrate 102;

[0045] Continuous material 114, the continuous material 114 is a continuous long strip or long tube, its cross section has a consistent shape, and can be further divided into multiple identical discrete materials 109;

[0046] Continuous material conveying device one 201, used for conveying continuous material 114;

[0047] The electronic label group conveying device 202 is used to convey the electronic label group 101, and the continuous material conveying device one 201 and the electronic label group conveying device 202 have a consistent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com