Method and device for pasting book labels, and label band used thereby

A label sticking and labeling technology, which is applied in the directions of labeling, labeling, transportation and packaging, etc., can solve the problems of difficult label tape production process, failure of the sticking process, and large peeling force, so as to save label transfer mechanism and steps, The effect of improving the paste efficiency and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

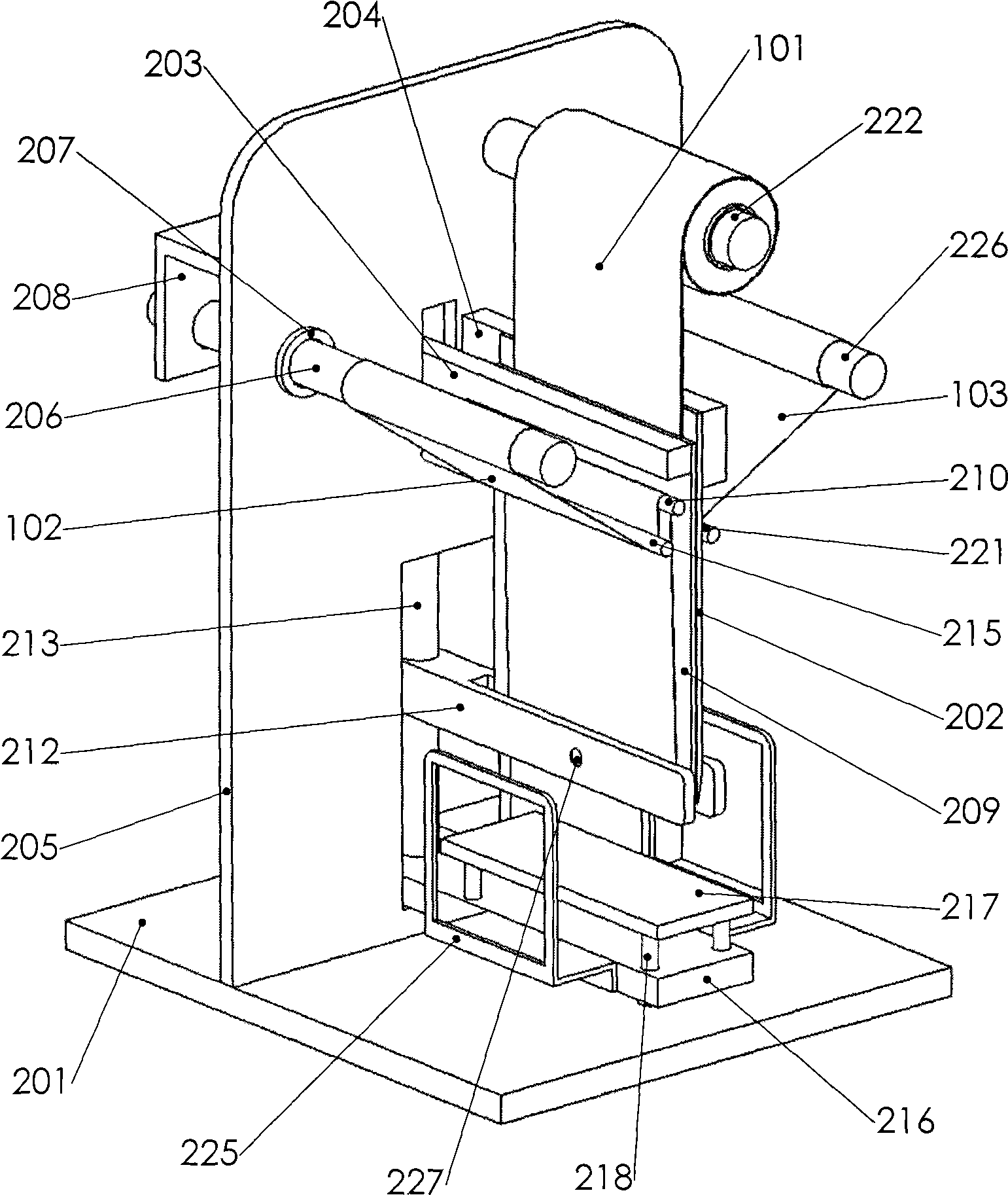

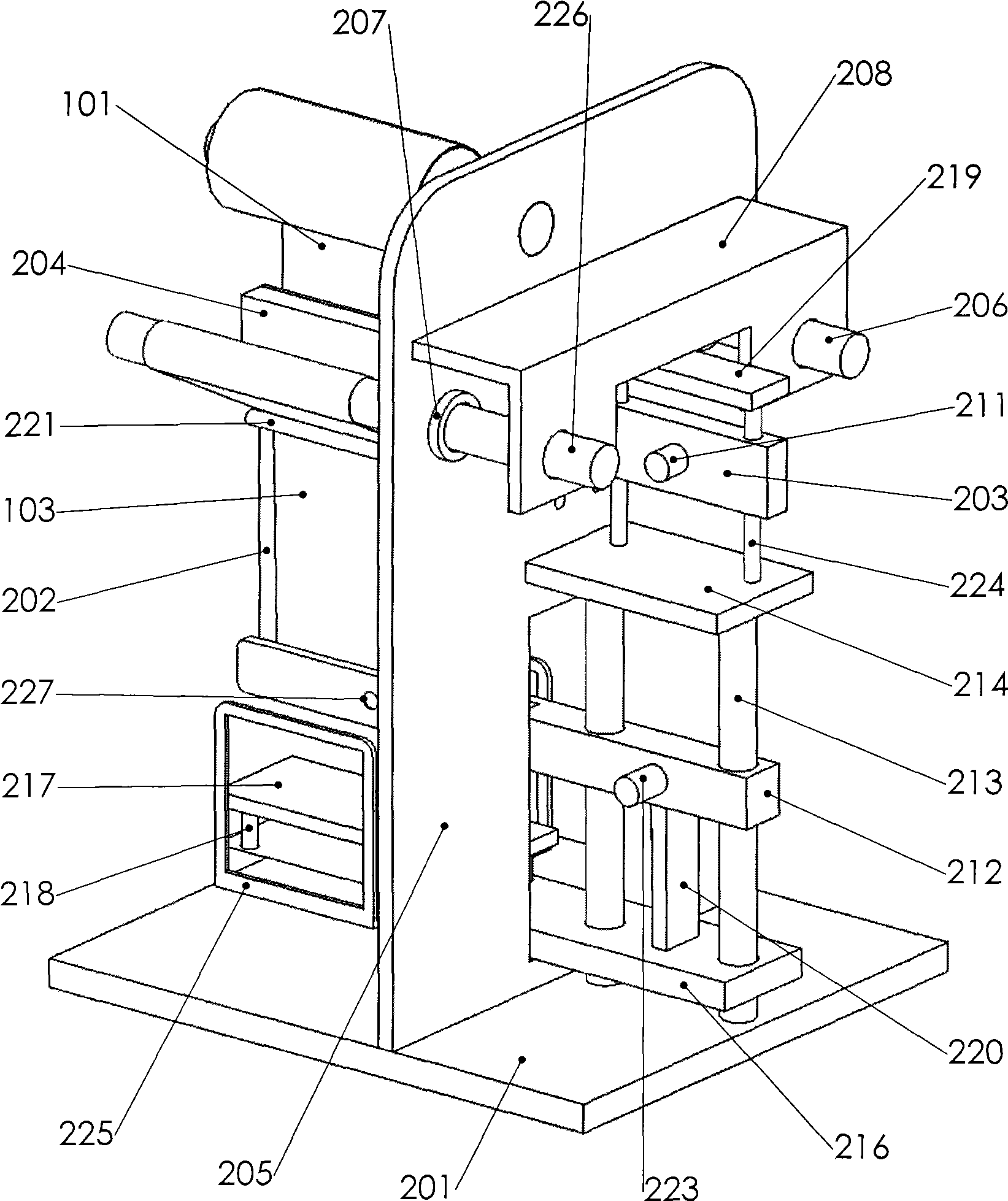

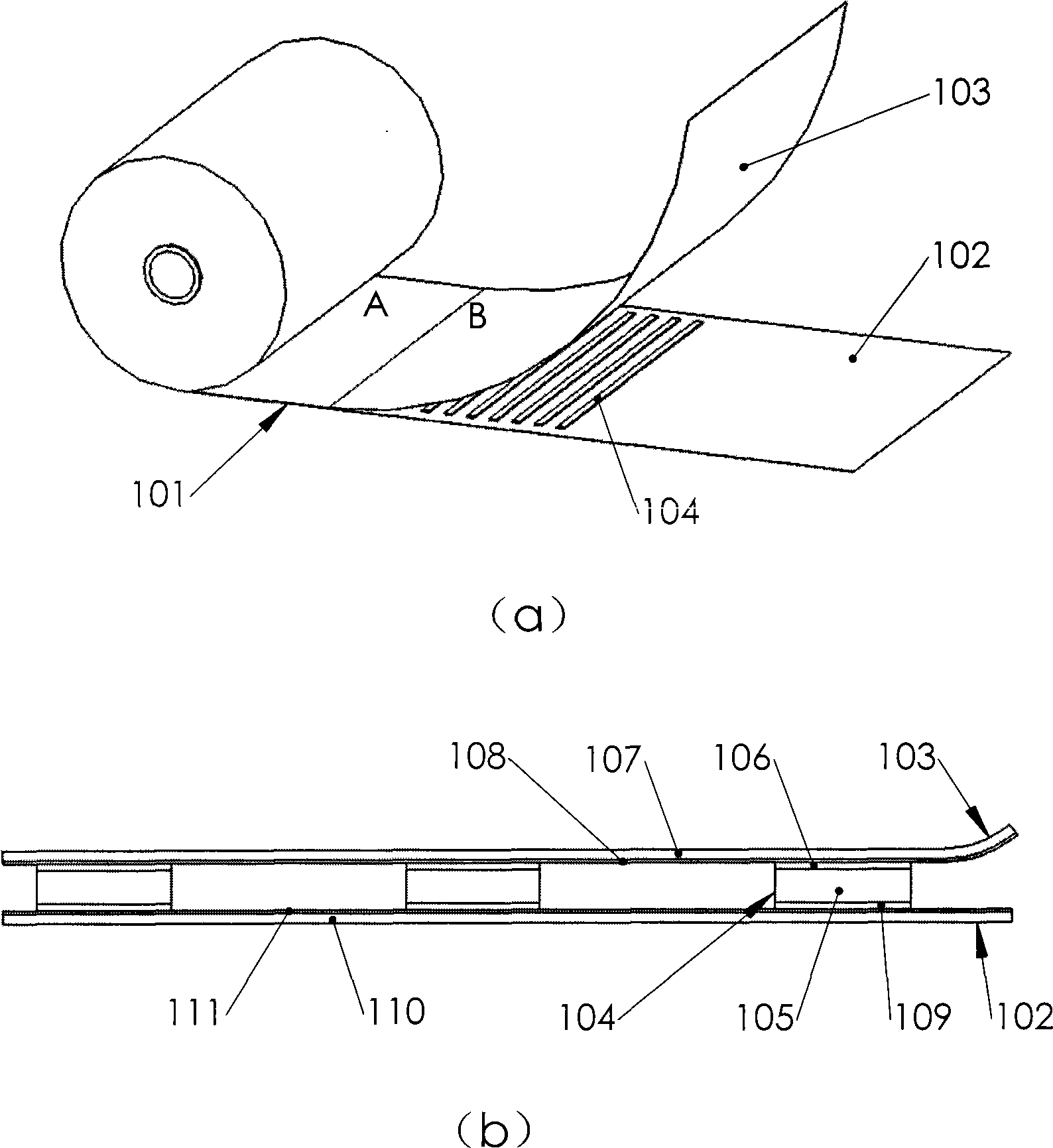

[0040] Embodiment 1: The label sticking device is described, figure 1 and figure 2 It is the front and back perspective view of the embodiment of the label sticking device, showing the specific internal structure and the relationship between the various components. It mainly consists of the following mechanisms: sticking jig, label strip pulling mechanism, jig moving plate toggle mechanism, jig moving plate 1 Side lining with pull and release mechanism and insert push mechanism. The pasting fixture includes a fixed plate and a moving plate. The surfaces of the two plates face each other, and there is a gap between the two plates for the passage of the label strip; the label strip pulling mechanism includes two reels, which are respectively wound and pulled from the pasting fixture. The two-layer backing tape of the label strip drawn from the exit of the gap; the toggle mechanism of the moving plate of the pasting fixture, pushes the moving plate of the pasting fixture to ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com