Experimental device for researching drill column dynamic characteristic

A technology of dynamic characteristics and experimental equipment, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as difficult to truly reflect the vibration of the bottom hole drilling tool and the attenuation of lateral vibration of the drill string. To achieve the effect of accurate and feasible research experiment data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

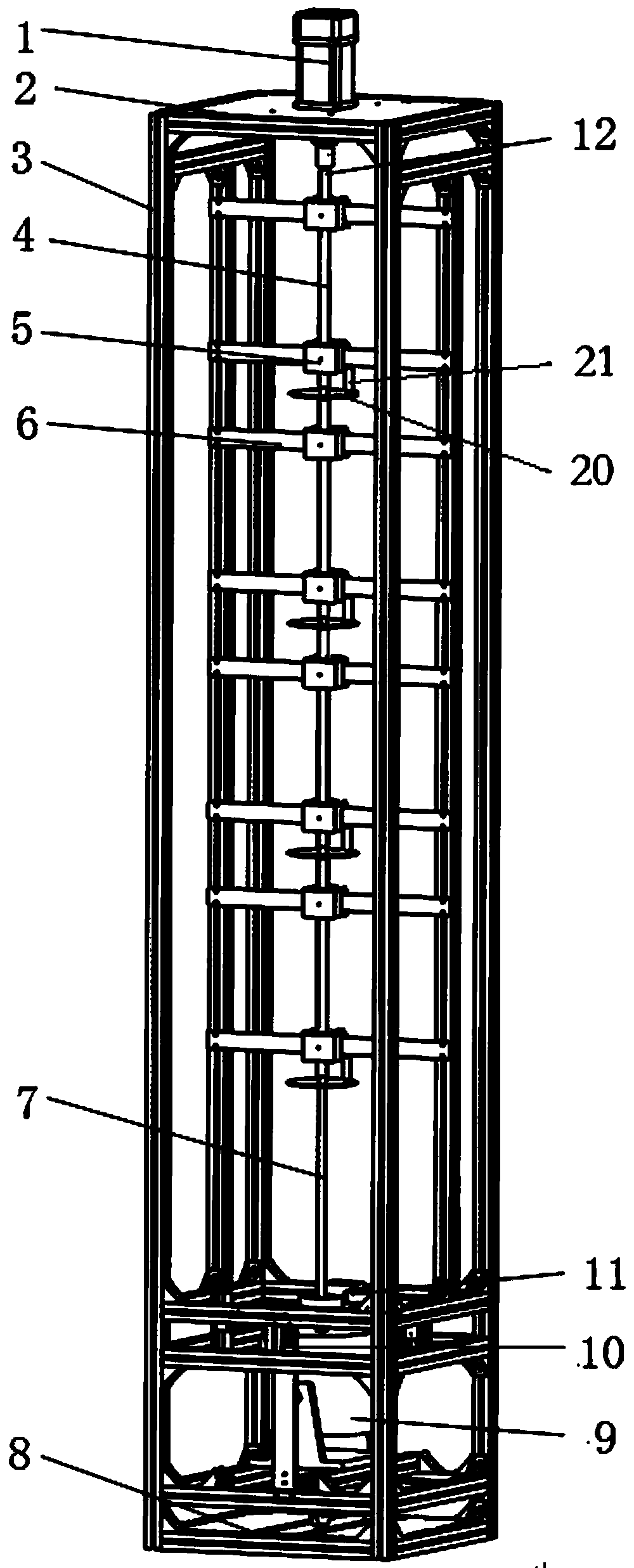

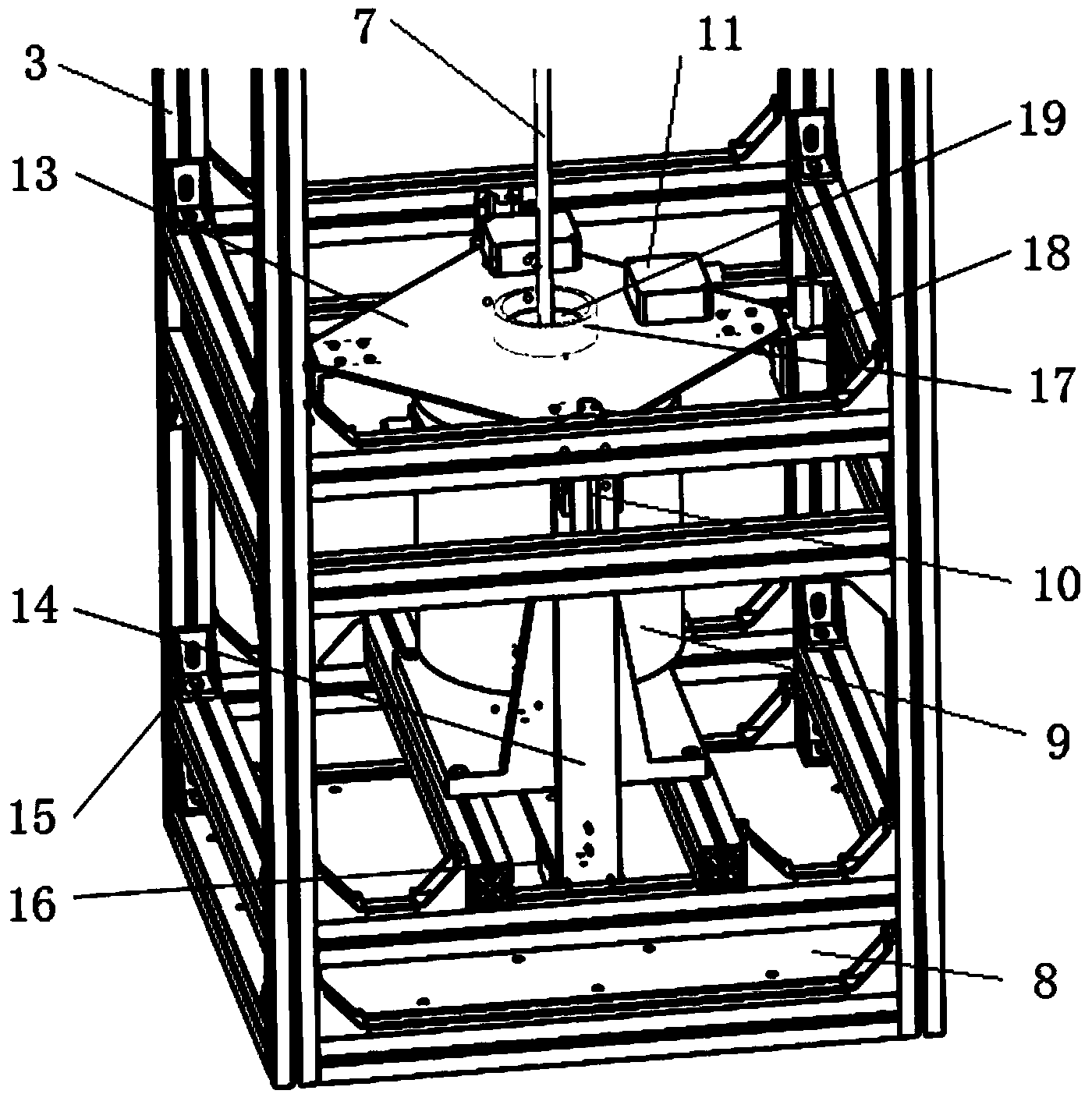

[0035] Embodiment 1: The present invention provides an experimental device for studying the dynamic characteristics of a drill string, including a main frame, a simulated borehole wall assembly, a rotary assembly, a disk assembly, an excitation assembly, a weighing assembly and a detection device ;

[0036] The main frame is composed of a main frame 3, angle links and connecting bolts and nuts 15;

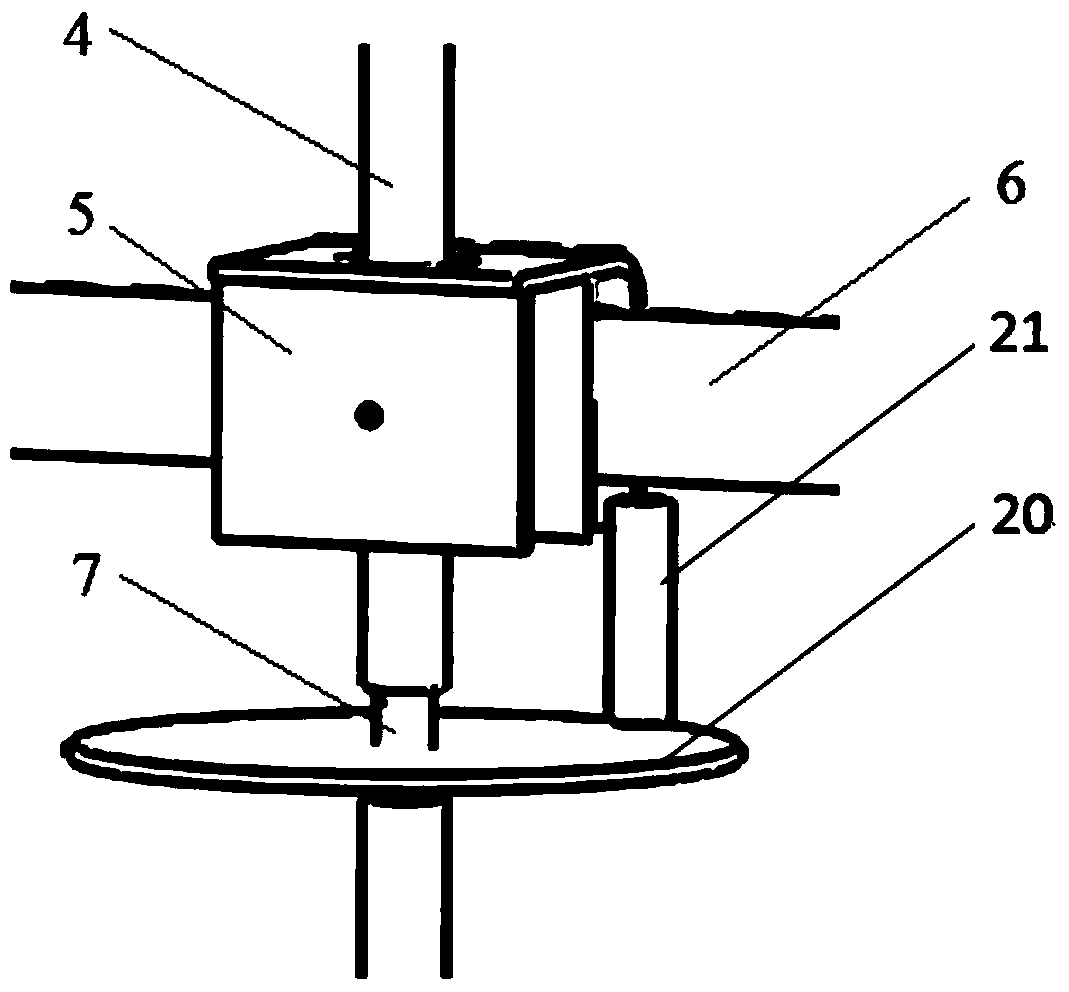

[0037] The simulated well wall assembly includes a plexiglass tube 4, a fixing fixture 5, and a fixture mounting plate 6. The plexiglass tube 4 passes through the fixing fixture 5 and is fixed in the fixing fixture 5, and the fixing fixture 5 is fixed on the fixture mounting plate 6 Above, the fixture mounting plate 6 is installed on the main frame 3 through bolts and nuts, and the thin steel column 7 passes through the plexiglass tube 4. During the experiment, the thin steel column 7 is in contact with the plexiglass tube 4 to simulate the relationship between the drill string and...

Embodiment 2

[0046] Embodiment 2: the present invention provides a kind of experimental equipment of research drill string dynamic characteristic, and the structure of experimental equipment is as figure 1 , used to study the drill string used in a certain drilling section, the type is: the outer diameter is 89mm, the inner diameter is 78mm; the outer diameter of the core bit is 95mm, the inner diameter is 63mm. Now it is necessary to conduct dynamic research on this type of drill string with a length of 20m, a weight on bit of 15kN, and a rotational speed of 450-600rpm. The method of simulation experiment is:

[0047] Step 1: Using the finite element method, the continuous drill string is discretized into a finite number of lumped masses in the borehole, and three adjacent lumped masses are taken: m k-1 ,m k ,m k+1 to analyze, such as Figure 4 shown.

[0048] Figure 4 middle: m k-1 ,m k ,m k+1 - Three consecutive lumped masses k-1, k, k+1 in the drill string discrete unit;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com