High-precision electric servo double-faced grinding machine

A double-sided grinding and electric servo technology, which is applied to optical surface grinders, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of low processing efficiency, low production efficiency, failure to meet processing accuracy and surface quality requirements, etc. problems, to achieve the effect of high grinding precision and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

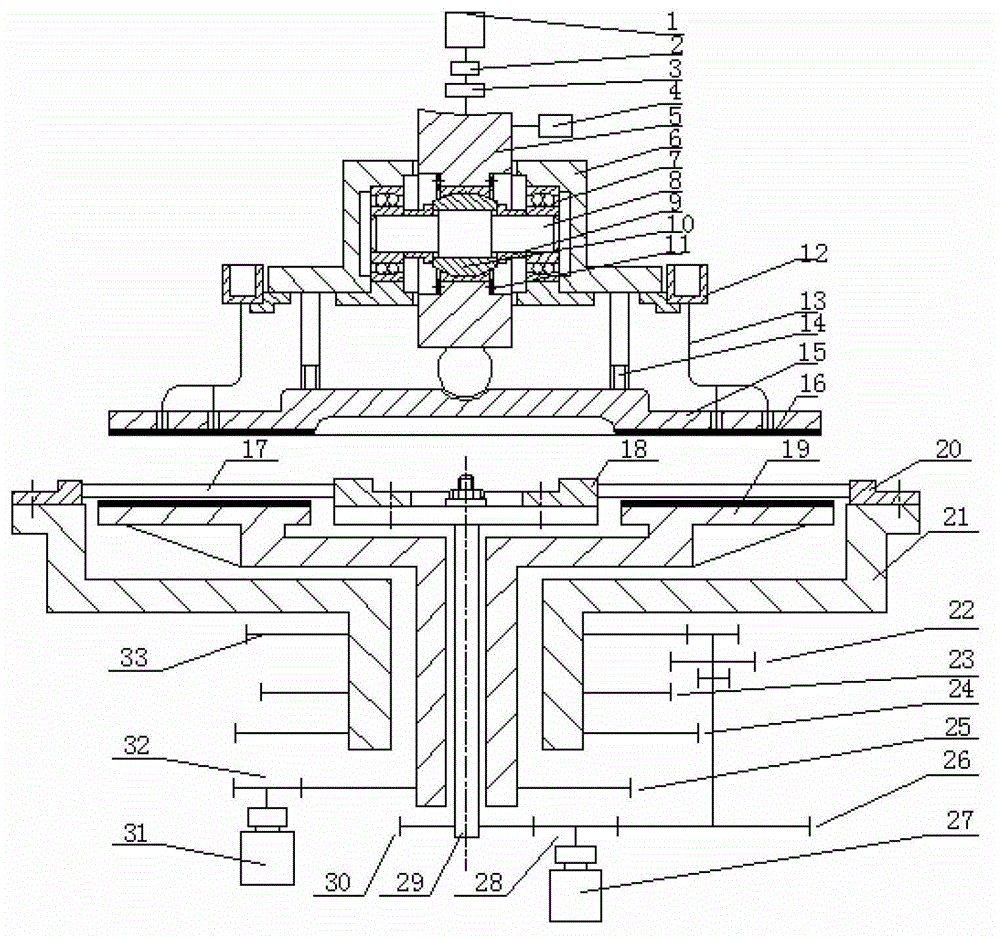

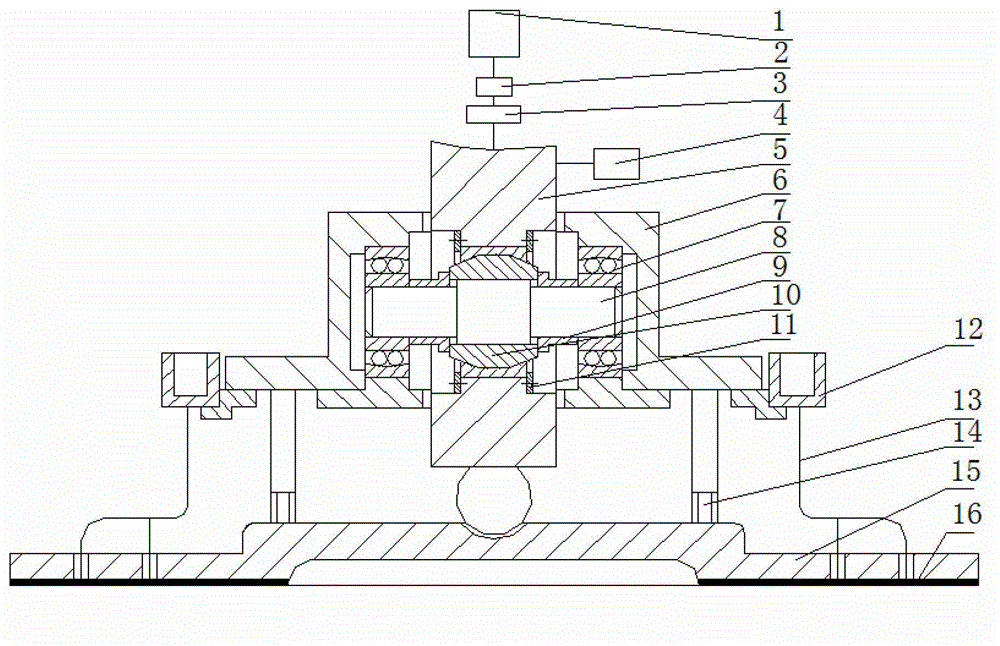

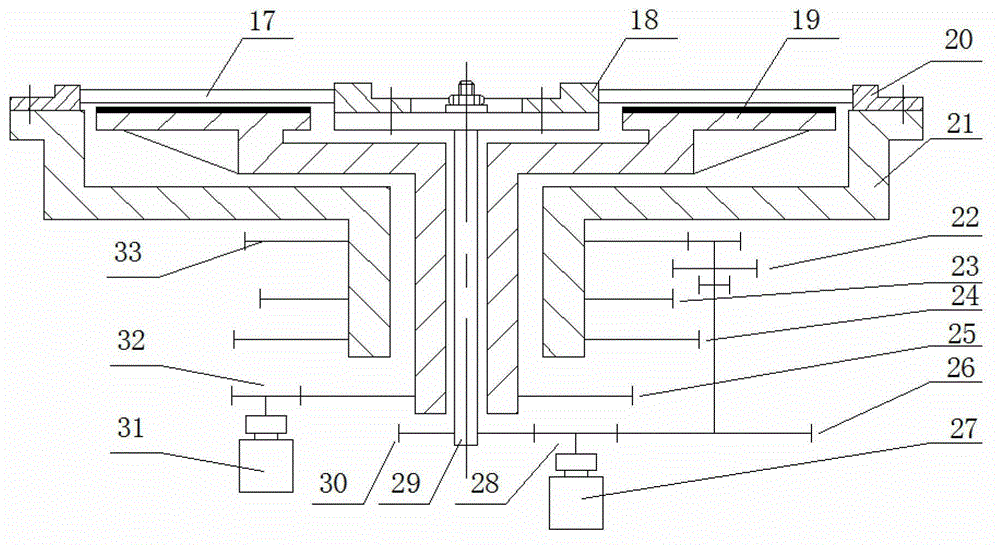

[0019] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, the present invention includes an upper grinding disc assembly and a lower grinding disc assembly, such as figure 2 As shown, the upper grinding disc assembly includes a servo electric cylinder 1, a segmented upper spindle 5, an upper grinding disc servo motor 4, an upper grinding disc seat 6, and an upper grinding disc 15. The segmented upper spindle consists of upper and lower segments The piston rod of the servo electric cylinder is connected to the upper end of the upper spindle through the cylinder pressure sensor 2 and the separator 3, and the longitudinal feed of the upper grinding disc is controlled by the servo electric cylinder to provide grinding power. The servo electric cylinder is externally connected to a PLC controller to realize precise control of the speed, displacement and pressure of the upper grinding disc. The upper grinding disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com