Full-automatic mesh belt pass-type ultrasonic spraying cleaning machine

A spray cleaning and fully automatic technology, applied in cleaning methods and utensils, cleaning methods using liquids, metal material coating technology, etc., can solve problems such as non-conformity, fin bending and deformation, and achieve high cleaning efficiency, Improve the appearance quality, avoid the effect of handling and turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

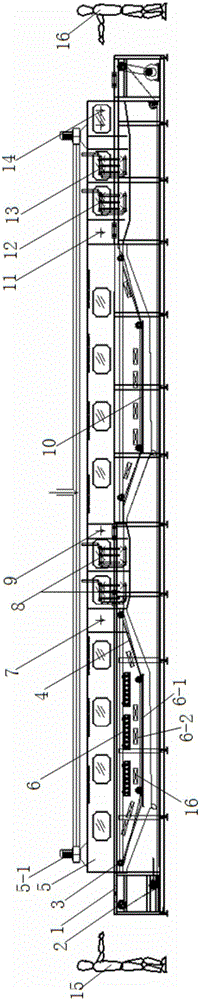

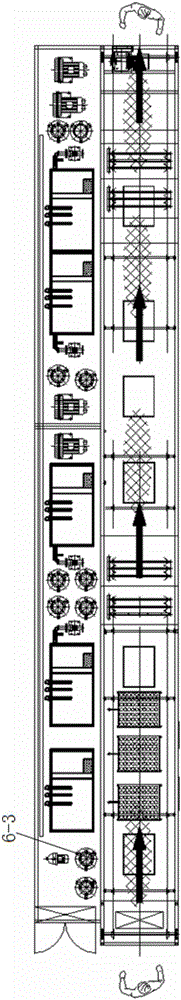

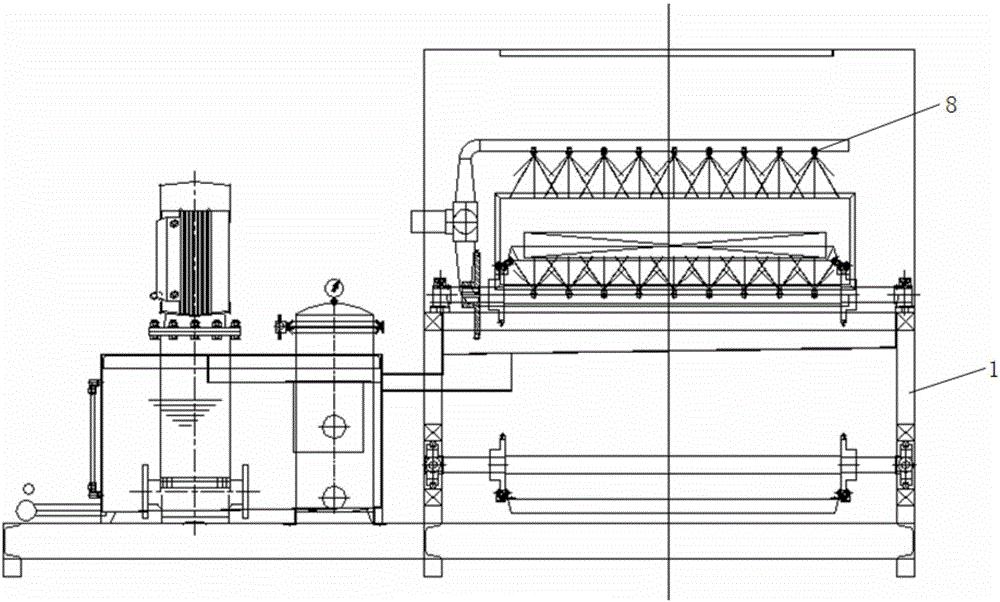

[0017] See attached Figure 1-3 Shown, a kind of full-automatic mesh belt through-type ultrasonic spray cleaning machine comprises frame 1 and motor 2 and roller shaft 3 that are located on described frame 1, and mesh belt 4 is installed on roller shaft 3 and on motor Driven by 2, it passes through the mist extraction system 5, the ultrasonic immersion device 6, the first water cutting nozzle 7, the first tap water spray rinsing nozzle 8, and the second water cutting nozzle arranged on the frame 1 from front to back. 9. Passivation tank 10, third water cutting nozzle 11, second tap water spraying and rinsing nozzle 12, pure water spraying and rinsing nozzle 13 and wind cutter 14.

[0018] Preferably, the motor 2 is a variable frequency motor.

[0019] Preferably, the width of the mesh belt 4 is not less than 900mm.

[0020] Preferably, the mist extraction system 5 includes at least one set of exhaust fan motors 5-1.

[0021] Preferably, the ultrasonic immersion device 6 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com