Cutting device for demi-carcass pork

A cutting device and pork technology, applied in slaughtering devices, slaughtering accessories, metal processing, etc., can solve the problems of only one division at a time, prolong the time of carcass division, increase the probability of meat contamination, etc., and avoid multiple contact Pollution, high work efficiency, and the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

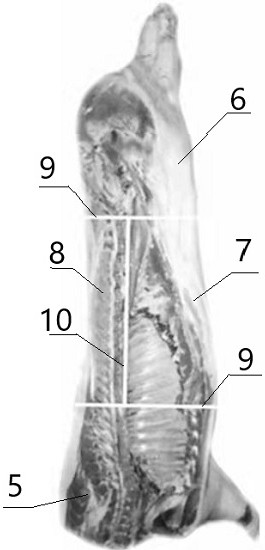

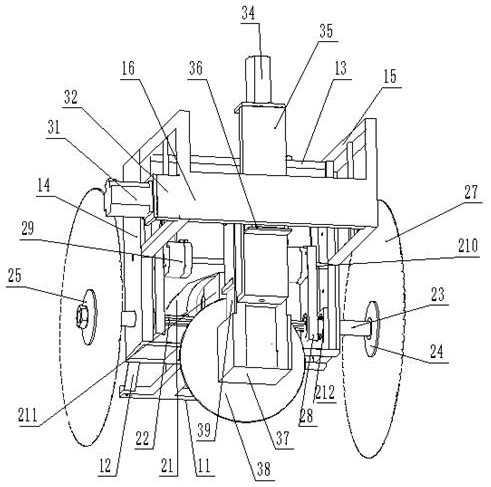

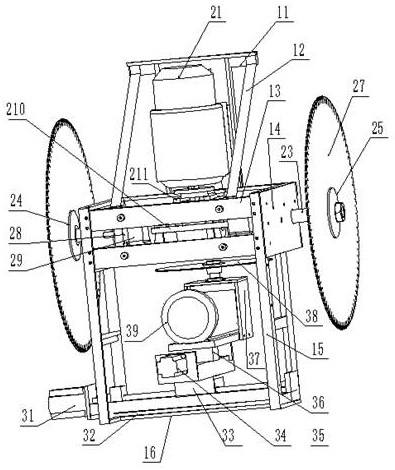

[0034] as Figure 1 、 2 ,3,4,5,6,7,8, the cutting apparatus of one piece of pork of the present invention, comprising an assembly frame 1, a double saw blade cutting mechanism 2 and a single saw blade cutting mechanism 3. The structure of the assembly rack 1 is as follows Figure 4As shown, comprising a base frame 11, two side frames 15, a lifting plate 13 and a rear mounting rack 16, the rear mounting rack 16 and the side frame 15 is a rectangular flat or rectangular flat frame, the two side frames 15 are respectively vertically fixed on both sides of the rear mounting rack 16, the lifting plate 13 and the base frame 11 are relatively fixed between the two side brackets 15 of the side edges. The double saw blade cutting mechanism 2 as Figure 5 、 6 Shown, comprising two cross-cutting saw blades 27, shaft 22, cross-cutting motor 21, reducer 211 and support frame 212. The support frame 212 is two, the support frame 212 is vertically fixed to the base frame 11 of the assembly frame 1 p...

Embodiment 2

[0038] The present embodiment is based on Example 1 of the double saw blade cutting mechanism 2 optimized scheme design, double saw blade cutting mechanism 2 preferably the following scheme: e.g., Figure 3 、 5 , 6 shown: the axis 22 is a spline shaft, the spline shaft 22 at both ends of the slide are provided with spline bushing 23. Double saw blade cutting mechanism 2 when assembled with the assembly frame 1, the spline bushing 23 is mounted in the bearing on the two support frames 212, the two transverse cutting blades 27 are fixed at both ends of the spline bushing 23; the spline shaft 22 slides through the connection of two skateboards 28, the skateboard 28 and the spline bushing 23 fixed connection; the gap between the two pieces of the skateboard 28 runs through the screw 210, the thread at both ends of the screw 210 is a positive and negative wire, The opposite side of the two skateboards 28 is fixed with a sliding motor 29, the sliding motor 29 is a through motor, the slid...

Embodiment 3

[0042]The present embodiment is based on Example 2 of the single saw blade cutting mechanism 3 optimized scheme design, e.g., Figure 3 、 Figure 7 、 Figure 8 Shown: The rear mounting frame 16 of the assembly frame 16 is fixed with a left and right translation guide 32, both ends of the left and right translation guide 32 are fixed by the end plate 322 is connected to the left and right translation lead screw 321, the left and right translation lead screw 321 is set on the end plate 322 driven by the left and right translation motor 31; the left and right translation lead screw 321 screwed with a translation guide connection block 33, the back of the translation rail connection block 33 is fixed with an up and down moving rail 35, The up and down moving rail 35 is perpendicular to the left and right translation guide 32; the upper and lower moving guide 35 is fixed between the end plates of the upper and lower moving rail 35 is fixed to the upper and lower moving screw 351, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com