Clamping type feeding device of pre-pricking machine

A feeding device and clamping technology, which is applied in the field of clamping feeding devices of pre-punching machines, can solve the problems of long fiber web conveying distance, large traction rate, and large conveying resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

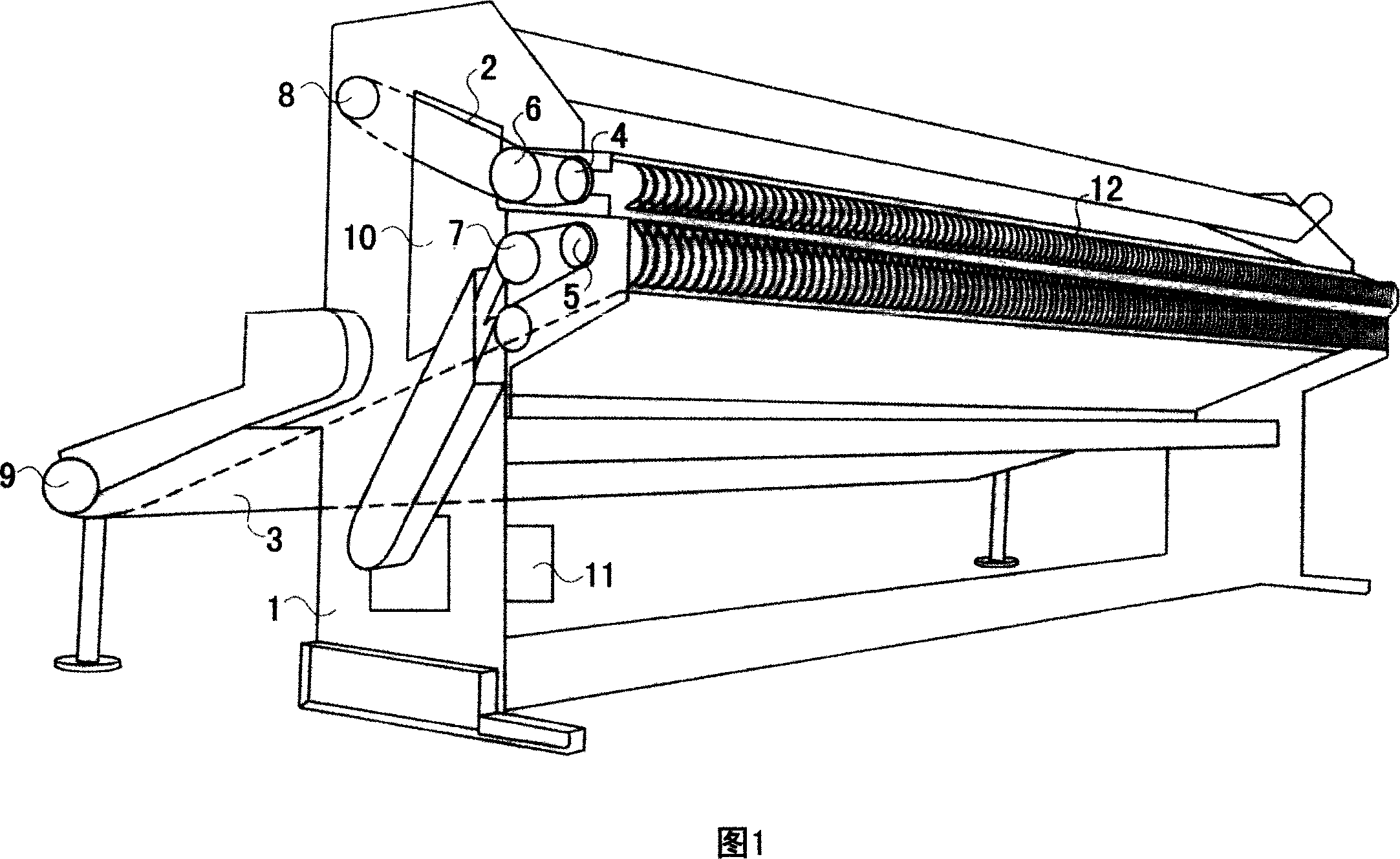

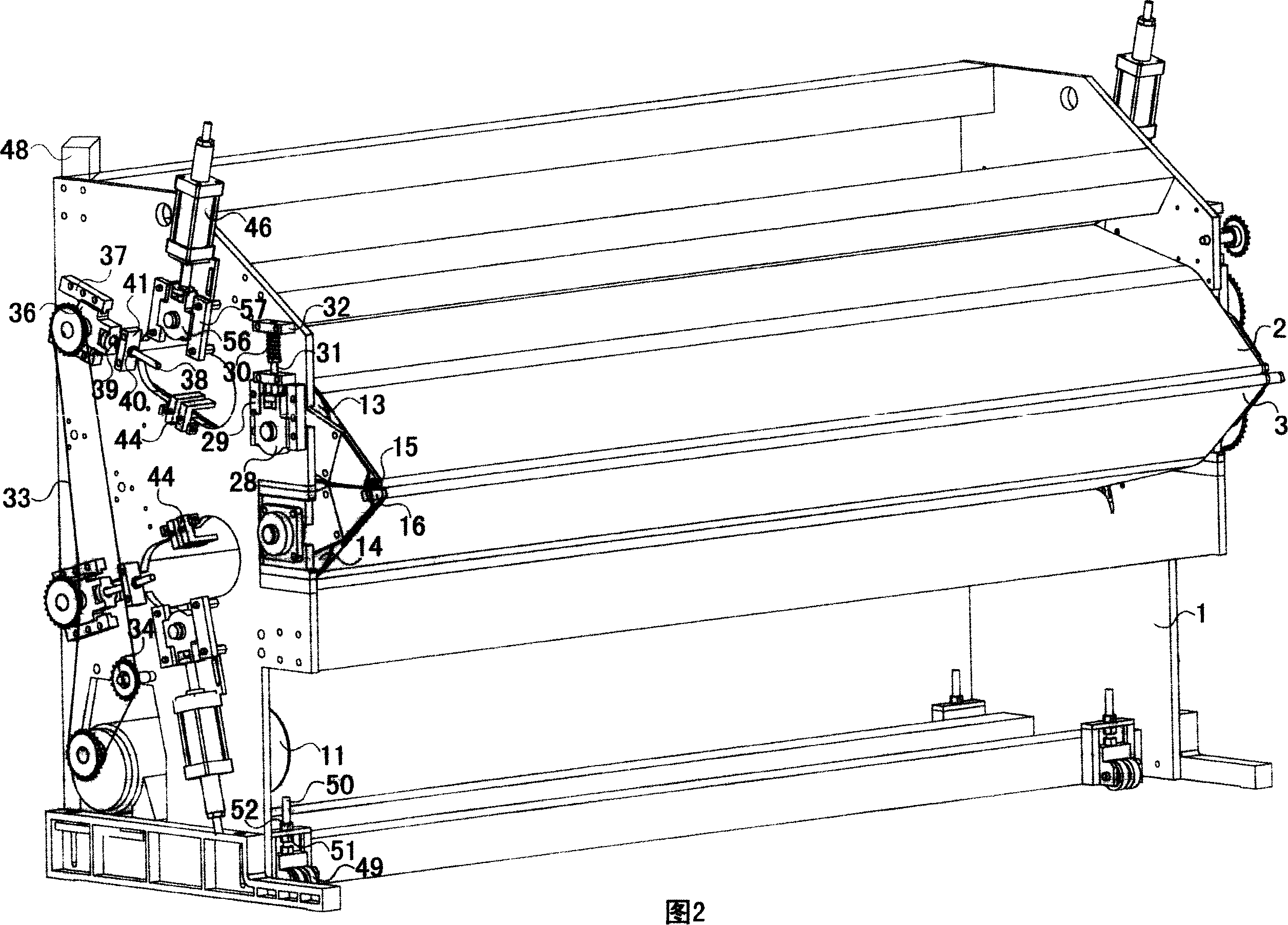

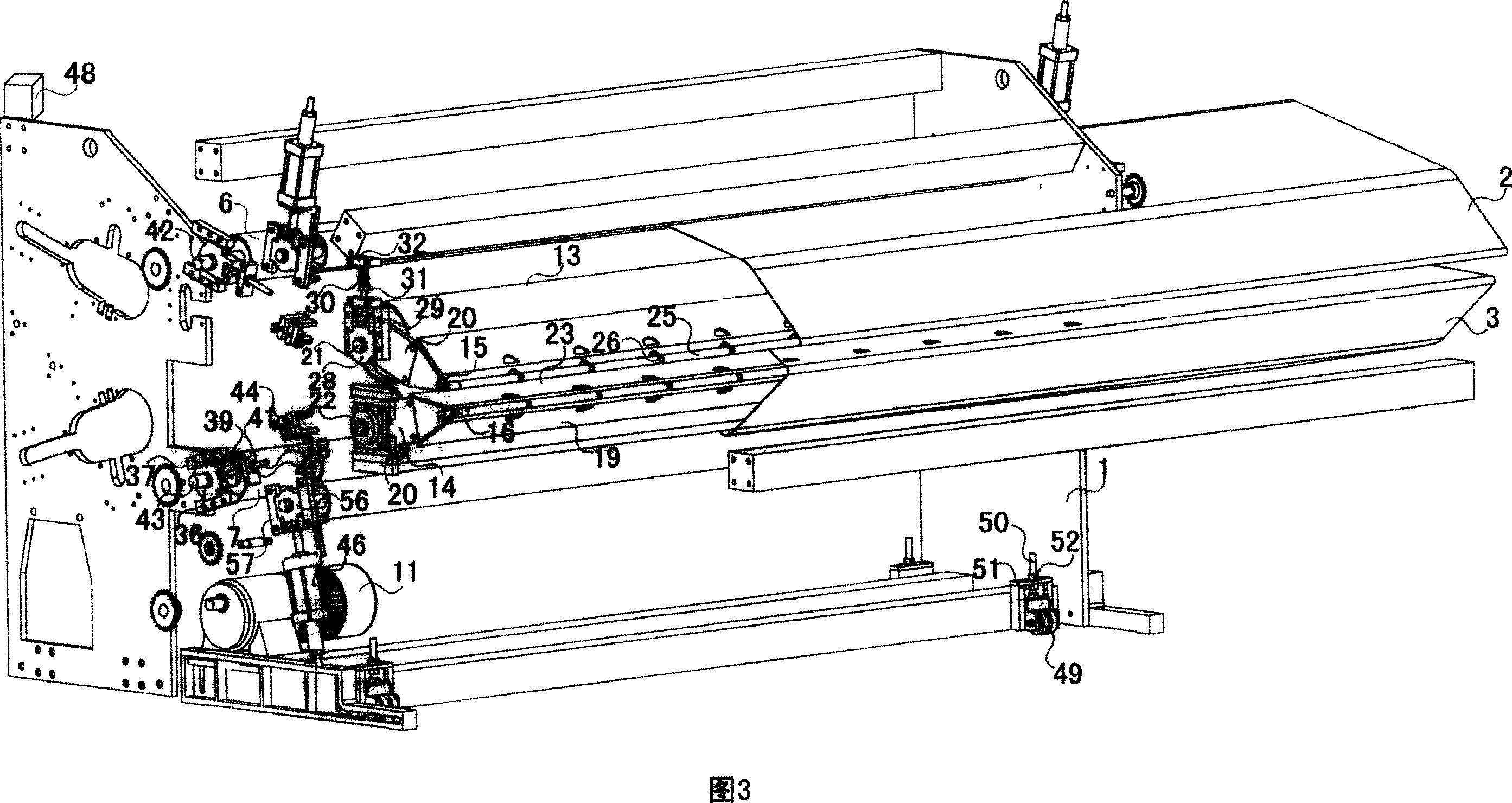

[0029] As shown in Fig. 2, Fig. 3 and Fig. 4, a clamping feeding device of a pre-punching machine includes a frame 1, a fiber web conveying mechanism and a power mechanism, and the above fiber mesh conveying mechanism and power mechanism are all installed on the machine On the frame 1, the power mechanism is connected with the transmission mechanism of the fiber web; Feeding small roller 15 and following feeding small roller 16, the two ends of upper and lower drive rollers 6,7 can be rotatably installed on the frame 1, and the two ends of upper and lower pressure rollers 13,14 can be rotatably Be installed on the frame 1; Upper and lower feeding small rollers 15,16 are respectively installed on the rotating shafts 13,14 of the upper and lower pressure rollers through the roller sleeve frame 17, and the upper and lower feeding small rollers 15,16 stretch out on the Outside the frame 1; the upper transmission curtain 2 is tensioned on the upper driving roller 6, the upper press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com