Supply device for delivering individualized separating fibres or fibre bundles to transport device

A technology of feeding device and conveying device, applied in the direction of fiber processing, fiber feeding, application, etc., to achieve the effect of improving regional resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

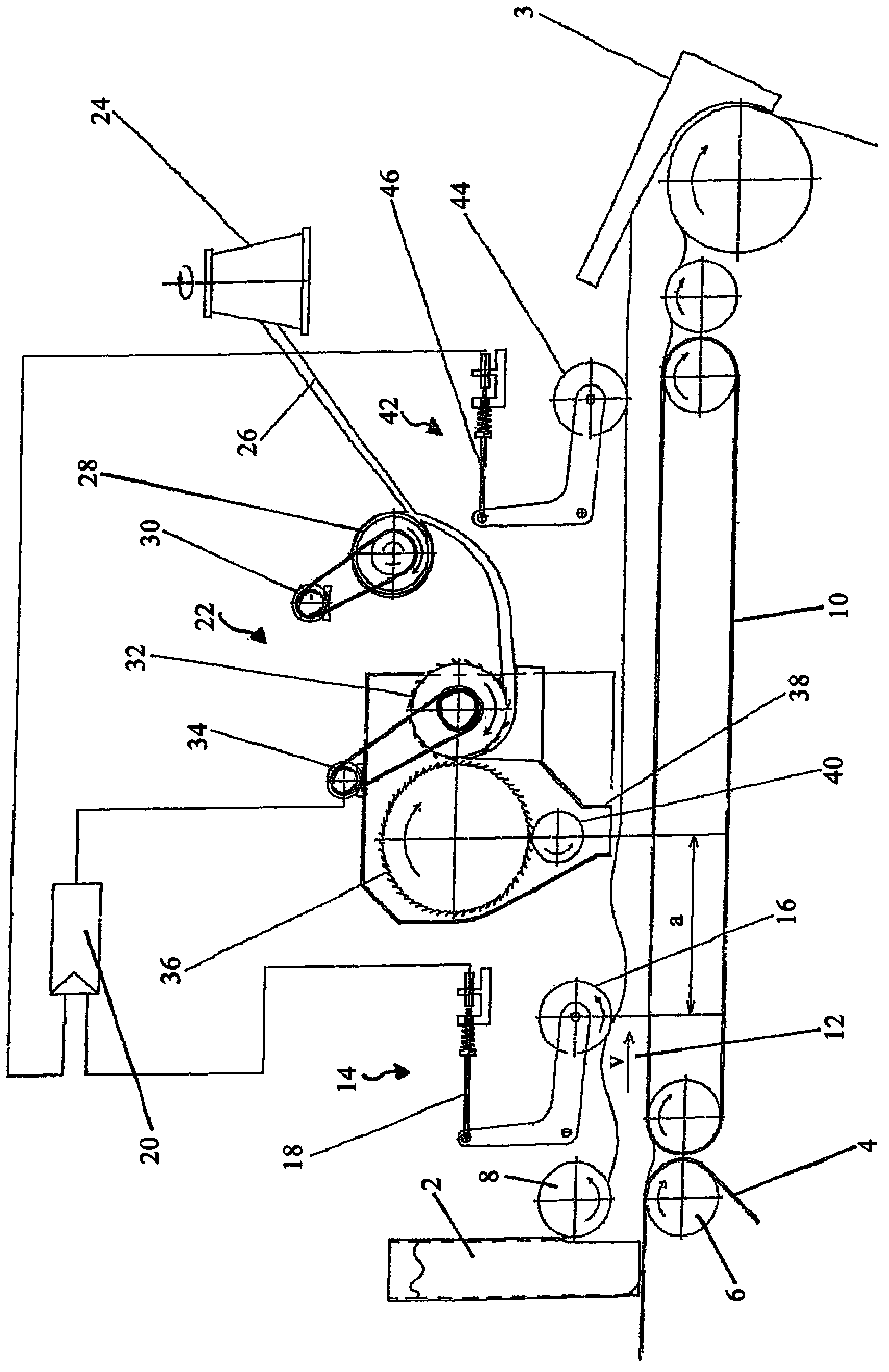

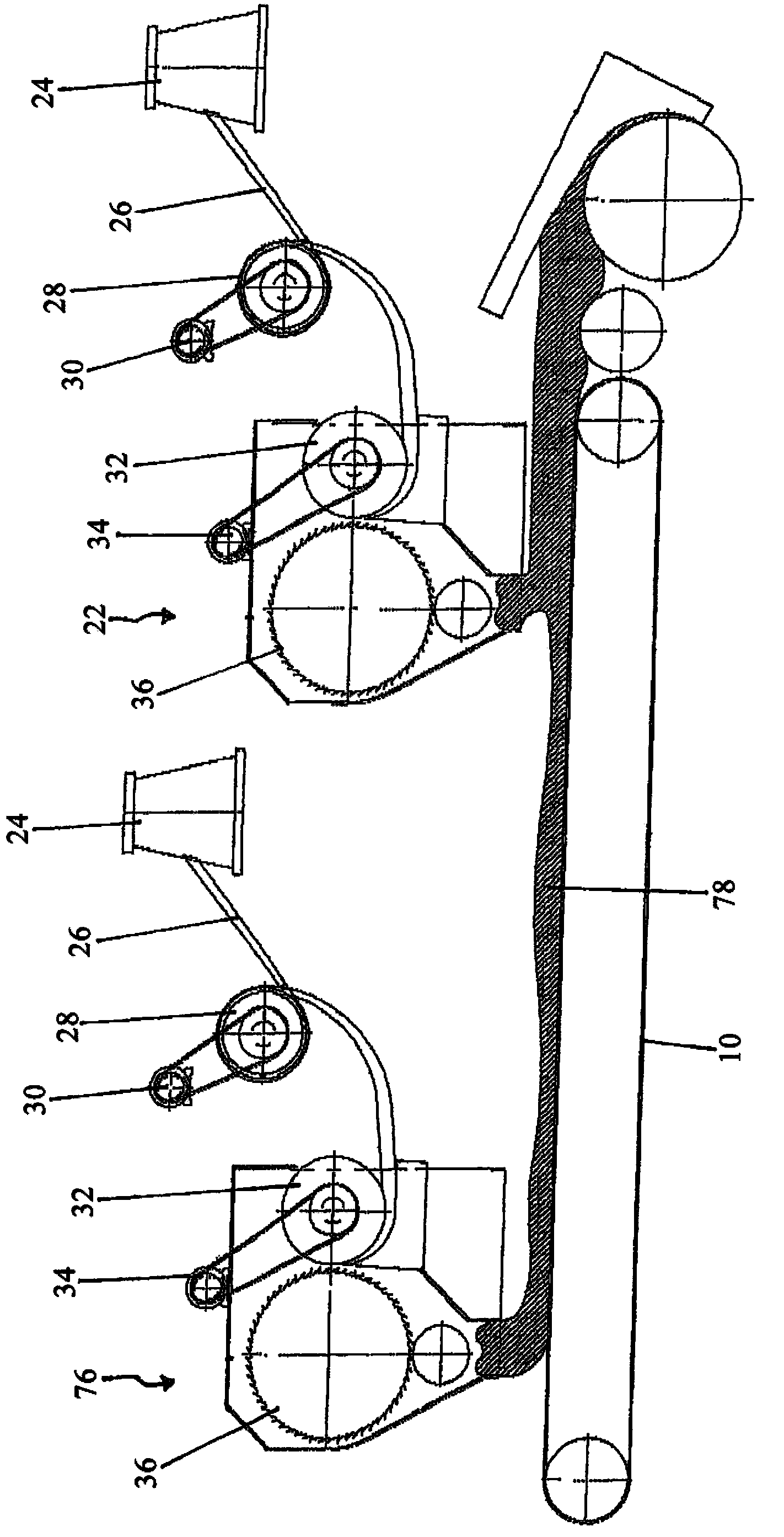

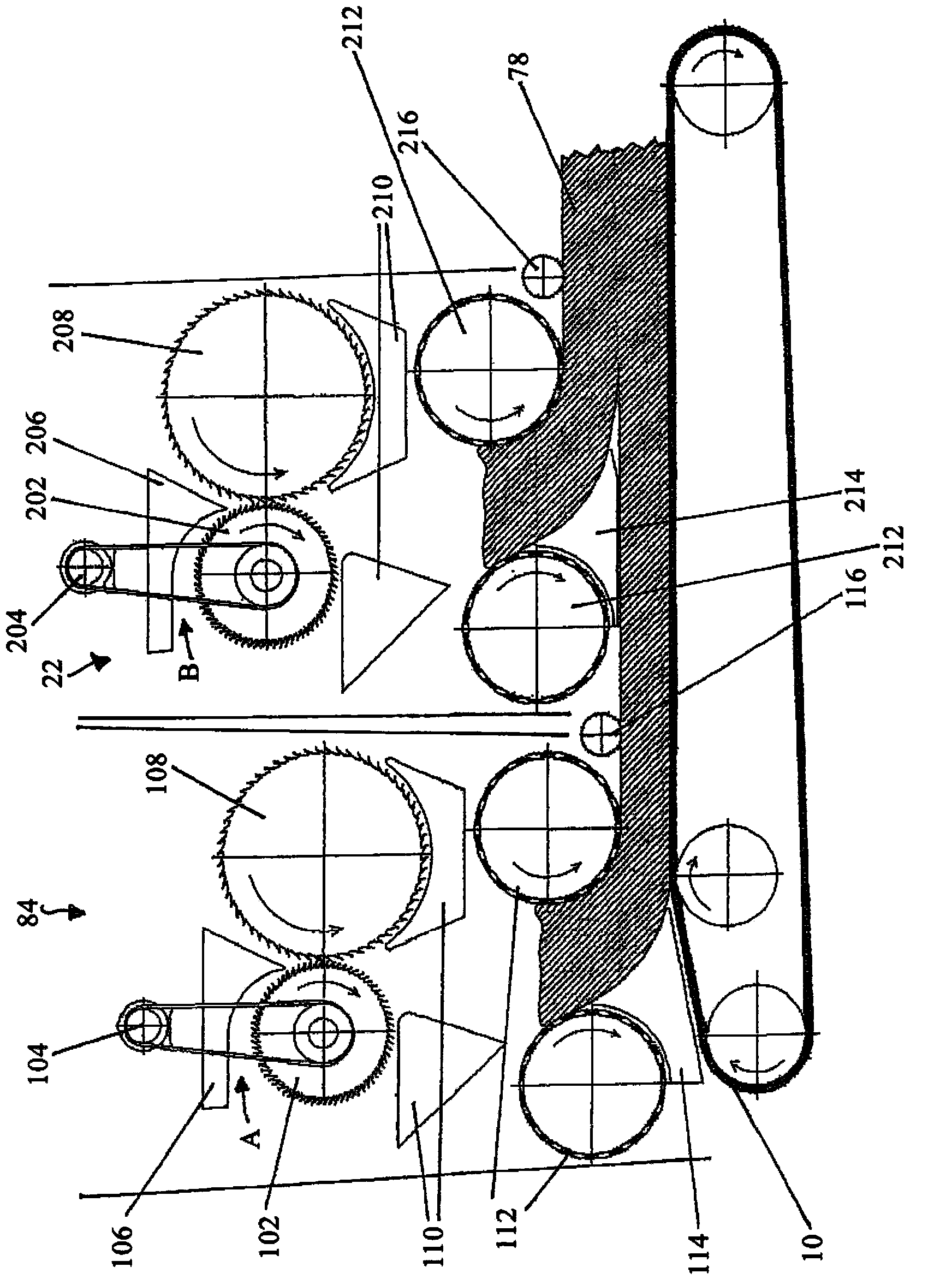

[0032] figure 1 Apparatus for forming mats of uniform or shaped fiber bundles is shown. The device includes a dosing device, which is designed here as a fiber tow feeder 2 . Downstream of this dosing device, the resulting fiber tow mat is conveyed to the infeed area of a web former 3, in particular a card. The resulting fiber tow mat 12 may also be conveyed directly to a pneumatic fleece former (not shown) or curing machine 50 (see figure 2 ).

[0033] The fiber bundle feeder 2 distributes the fiber bundles to the discharge conveyor belt 4, and the discharge conveyor belt 4 travels endlessly in circles and maintains tension through several deflection wheels 6, only one of which is shown in the accompanying drawings.

[0034] In order to increase the density of the tow material emerging from the tow feeder 2 , an upper drum 8 can also be arranged in the exit region of the tow feeder 2 . This upper roller 8 is driven in the opposite direction to the direction of the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com