Mixing output mechanism adapted for multi-column cotton mixer

A technology of mixed output and multi-silo cotton blending, applied in fiber mixing, textile and papermaking, fiber processing, etc., can solve problems such as damage, uneven mixing, and neps, and achieve the effect of solving damaged fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

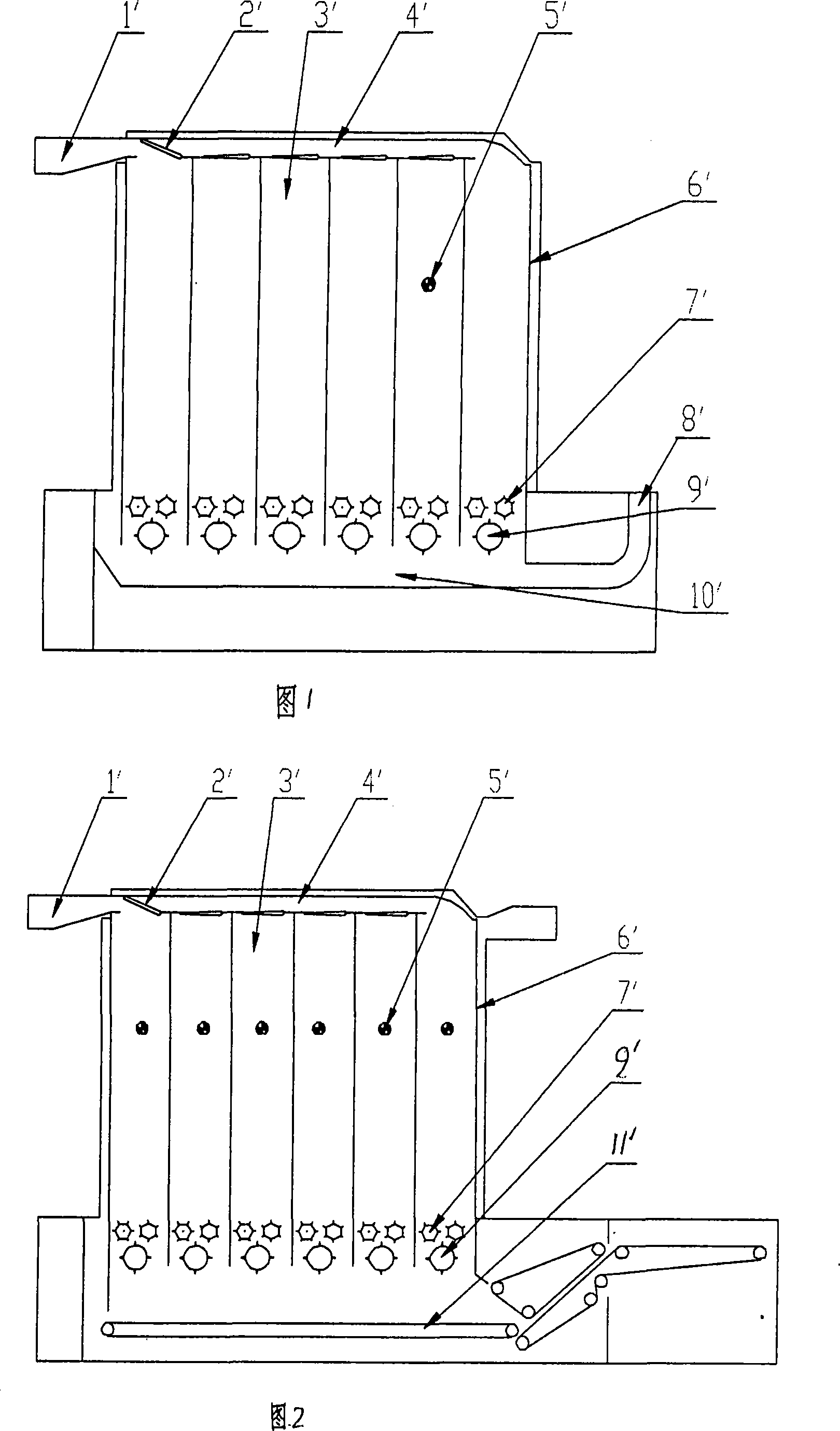

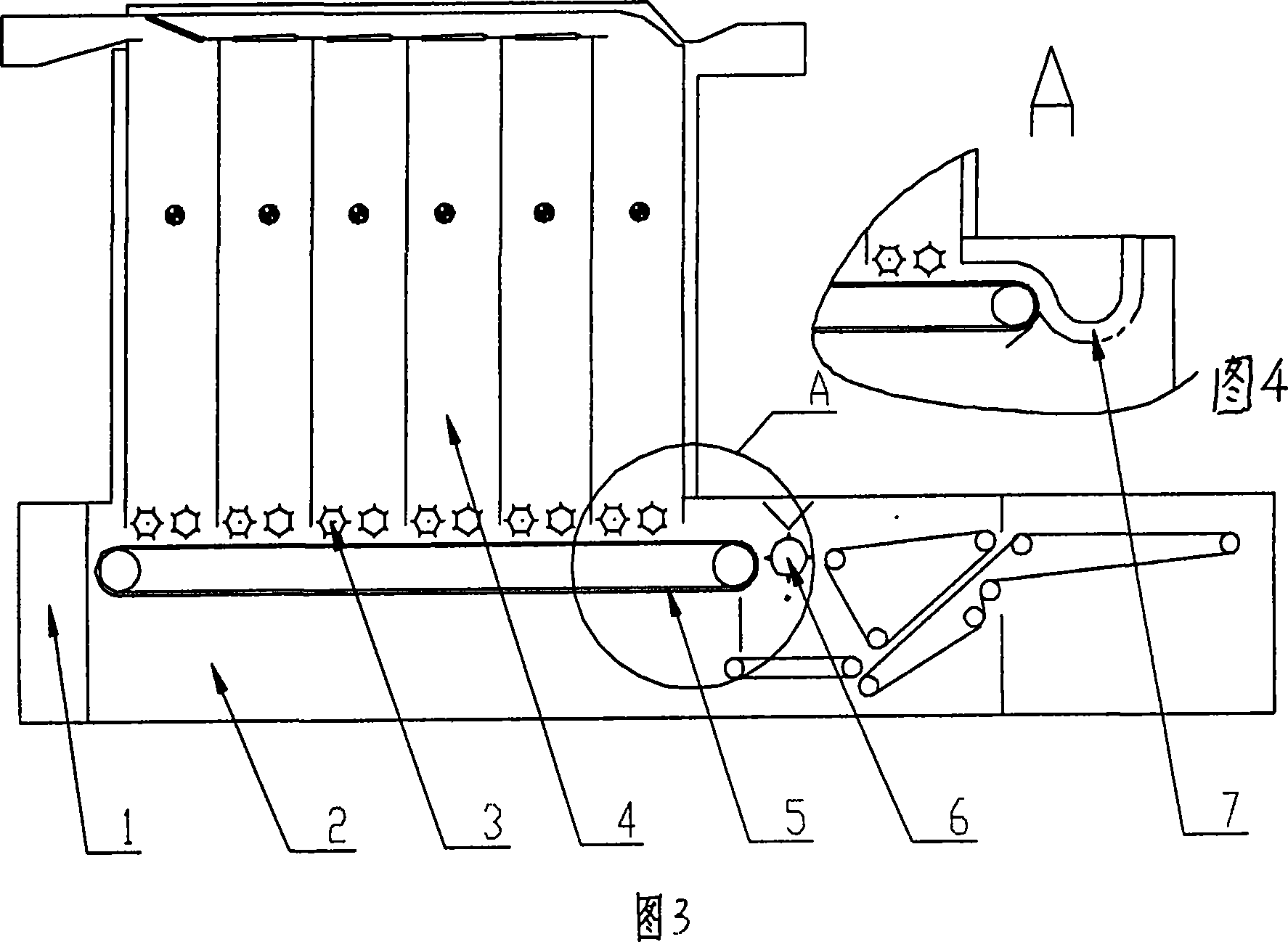

[0022] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

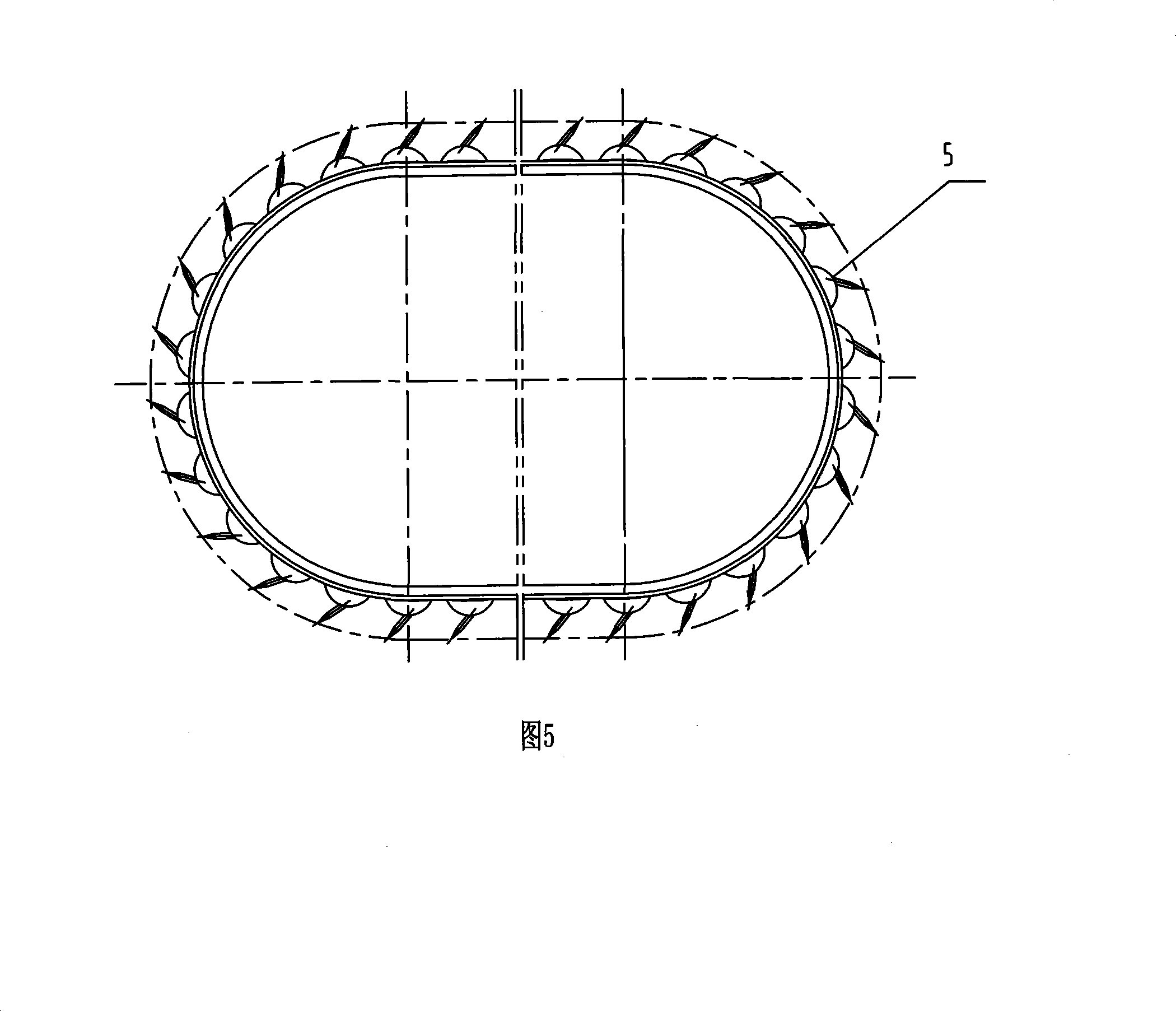

[0023] As shown in Fig. 3: the mixing output mechanism applicable to the multi-compartment blending machine of the present invention includes a number of mixing bins 4 arranged above the frame body 2 in sequence from front to back, and an inlet on the top of each blending bin 4. The feeding control valve through which the feed port passes is connected with the cotton distribution channel. At the cotton outlet below each mixing bin, a cotton delivery roller 3 is installed through bearings, bearing seats and connectors, and at the cotton outlet of the mixing bin 4 A horizontal grab brad curtain 5 is arranged below the bottom of the horizontal grab brad curtain 5, and between the cotton mixing output end of the horizontal grab brad curtain 5 and the cotton mixing transmission mechanism, there are several rows of hairs arranged by a circular cylinder and surrounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com