Autoleveling system with cotton silver weighing control and weight control method thereof

A self-leveling and weight control technology, applied in the field of textile machinery, can solve problems such as frequent tooth replacement, and achieve the effect of reducing labor intensity and improving detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] In the actual production process, in order to correct the weight deviation of the sliver, each operating shift laboratory must manually take samples and weigh them one by one. Generally, every 5 meters of sliver is used as a sample, and the weight of each sample is higher than the standard weight. If the weight is 1 gram (or 1 gram is too light), it is considered that the weight deviation has occurred. At this time, it is necessary to manually modify the given value of the autoleveler, that is, to adjust the speed of the cotton roller. Generally, the standard weight of sliver is 20g-30g / 5m, and the weight is 1g / 5m, that is, if the weight drift is detected by 3%-5%, manual correction is required.

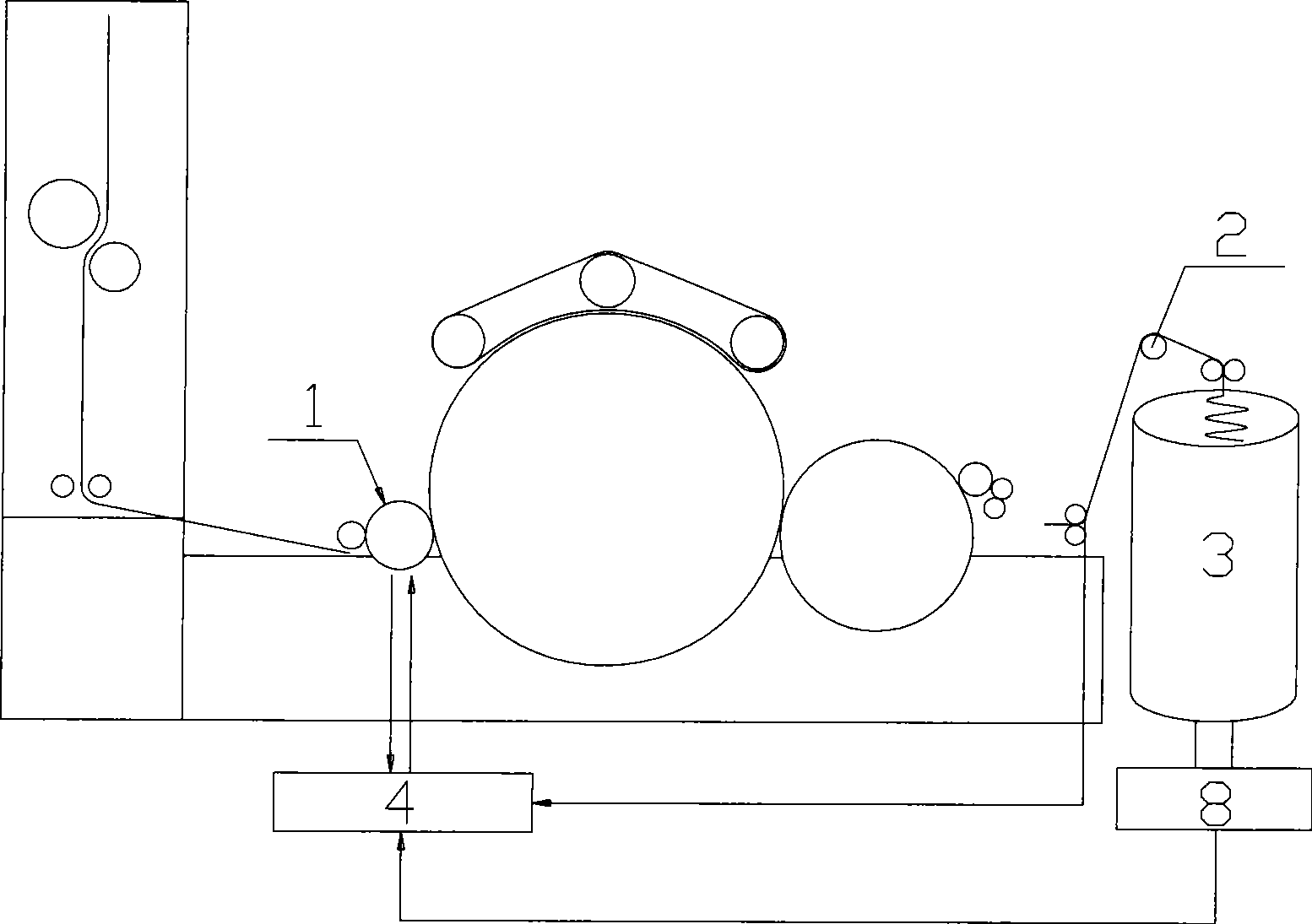

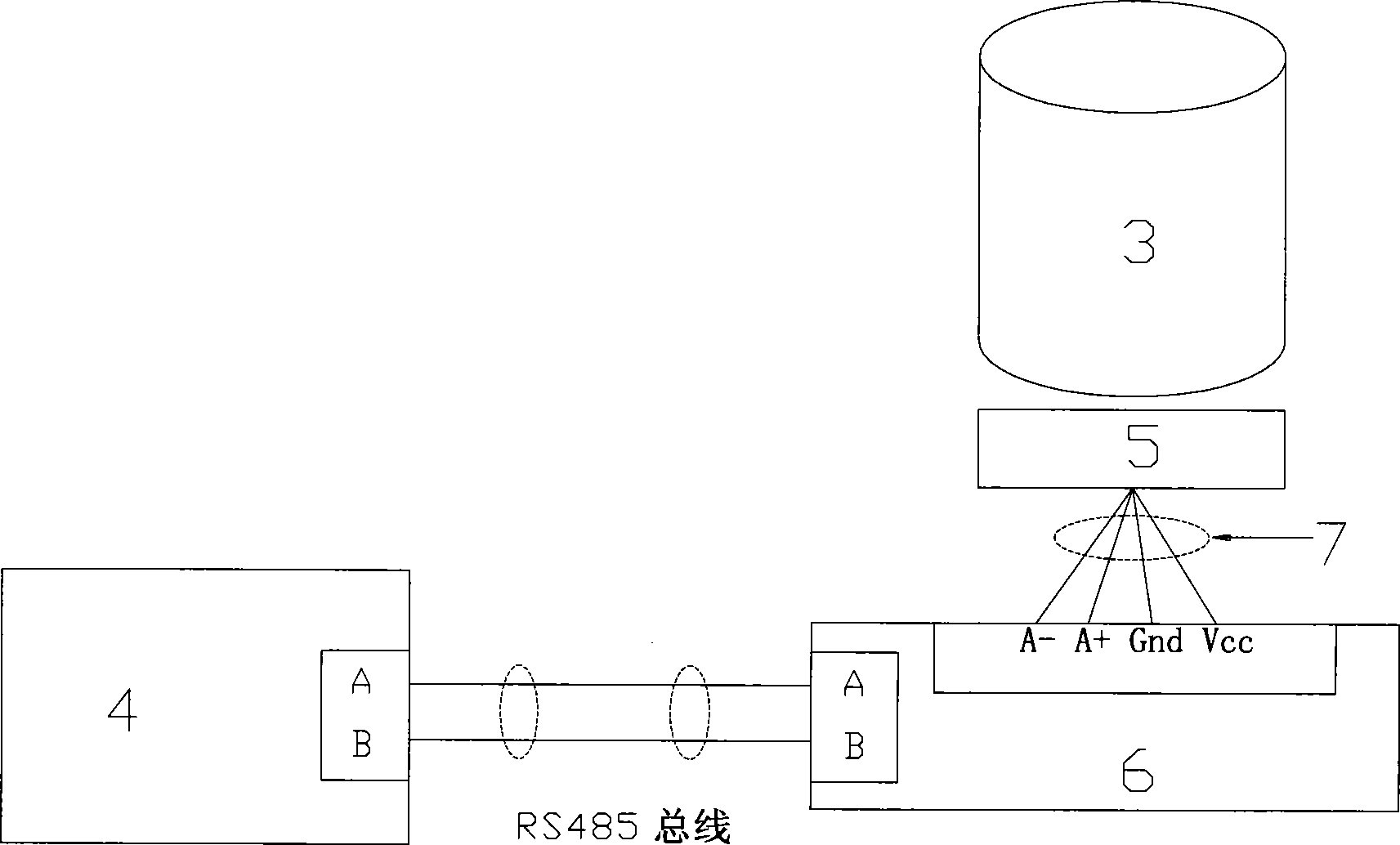

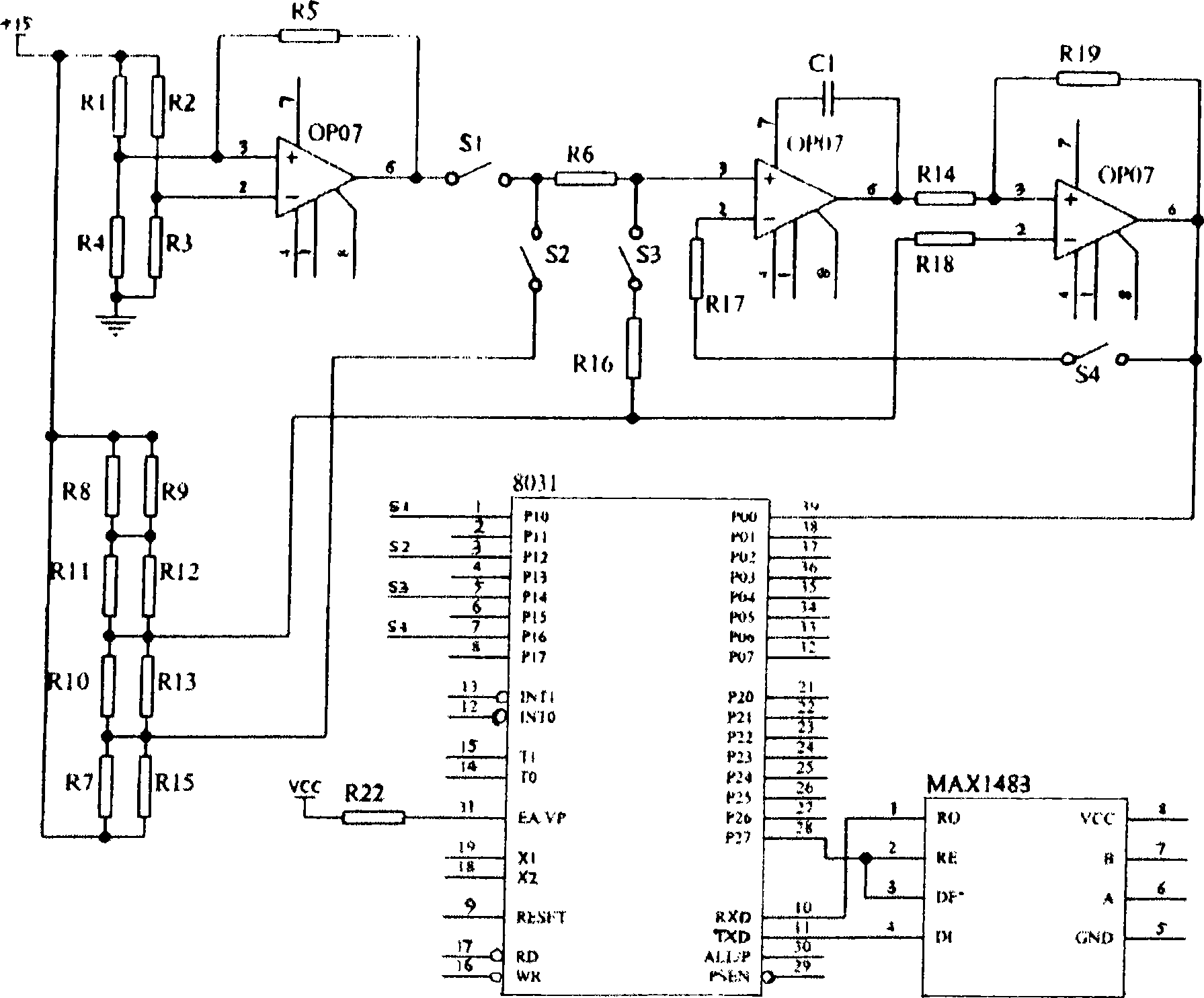

[0031] In order to realize on-line detection of the weight of the ultra-long segment sliver, and timely and effectively correct the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com