Apparatus in spinning preparation for separating foreign objects at conveying equipment for fibre material

一种输送设备、纤维材料的技术,应用在纺纱机、纤维处理、纤维喂入等方向,能够解决操作干涉、不方便、大空间等问题,达到减少分离、改善使用性、增大存储体积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

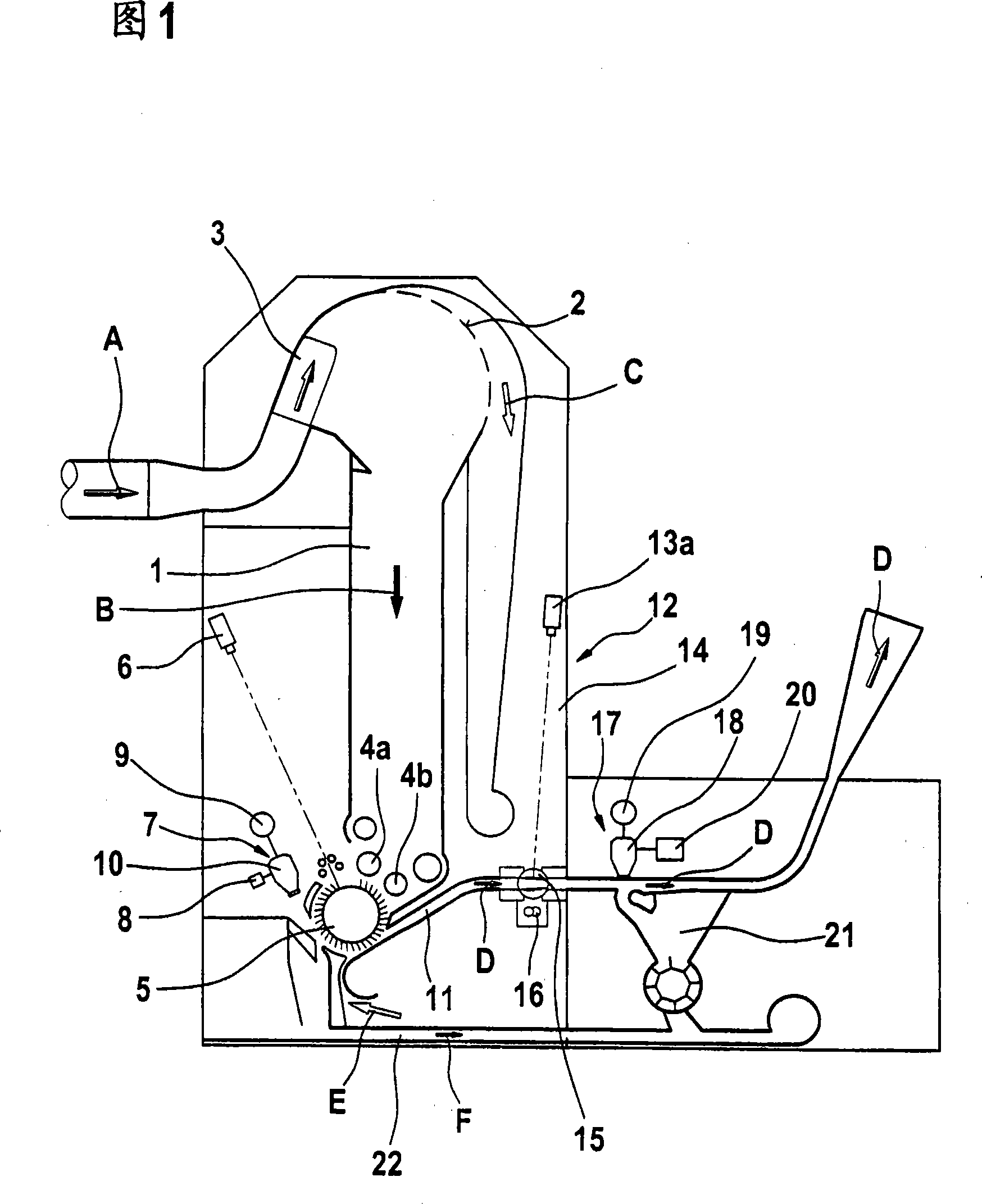

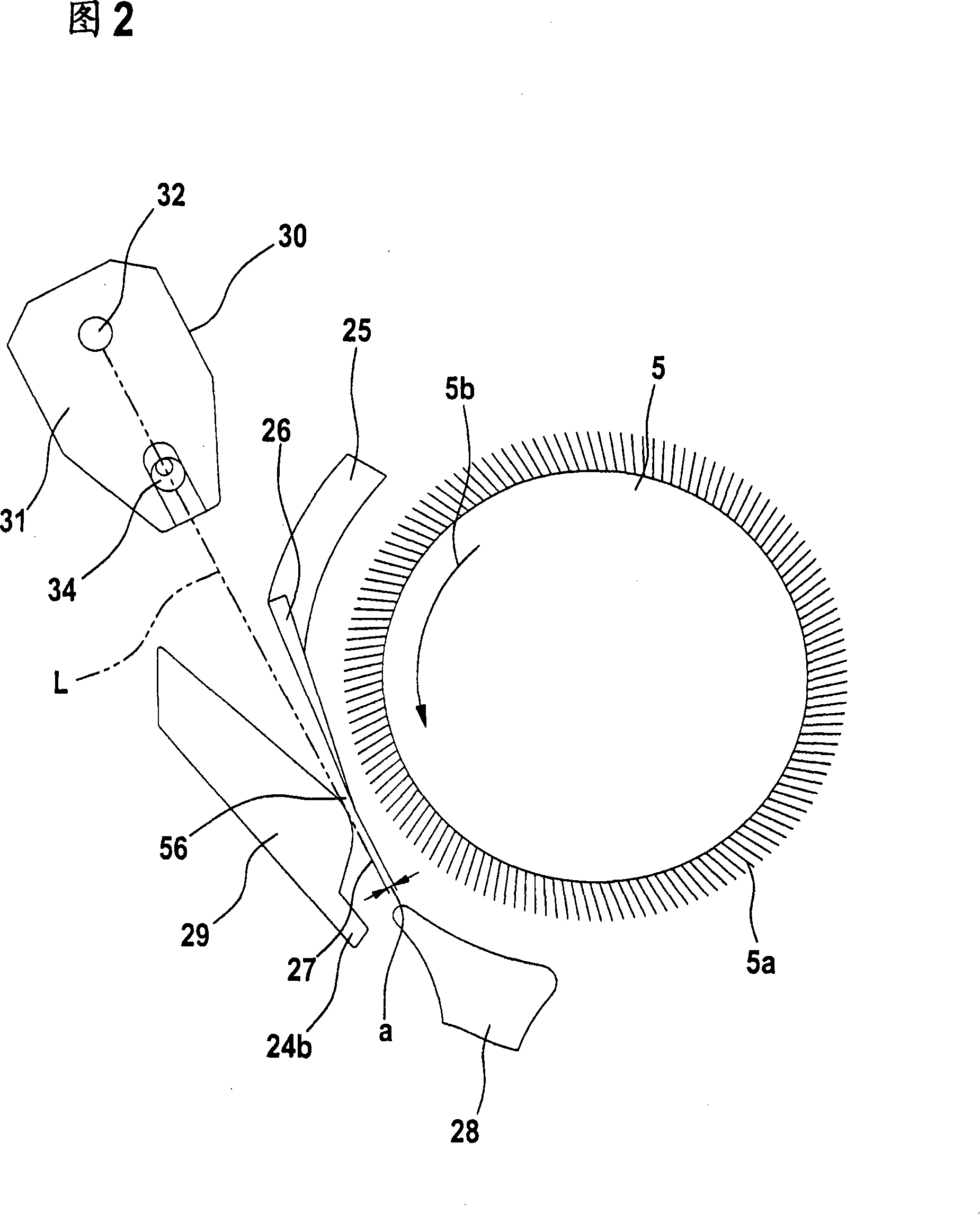

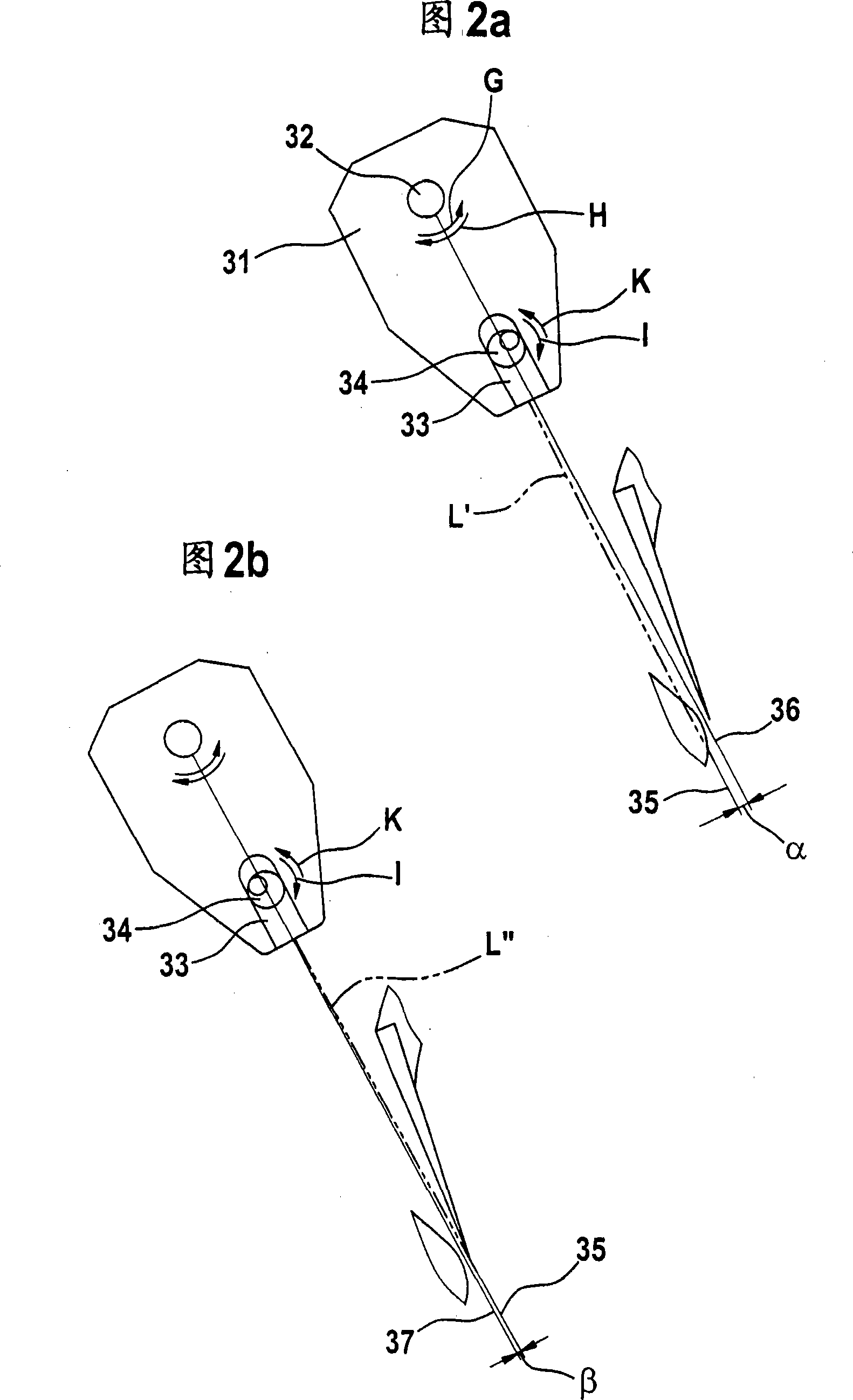

[0027] Referring to Figure 1, in a device for detecting and separating foreign matter, for example in the Trützschler foreign matter separator SECUROMAT SP-F2, the upper inlet opening of the supply tank 1 is connected with the equipment for the pneumatic supply of fiber-air flow A, which consists of Fibrous material conveying fan (not shown), stationary air permeable surface 2 for separating (spraying) fibrous material B from air C by means of air extraction, and air flow guiding means 3 with movable elements; laterally on air permeable surface 2 The fibrous material in the airflow is repeatedly guided back and forth, and after the impact, the fibrous material basically falls from the air-permeable surface 2 due to gravity and enters the feed trough 1 downward. The slow rolls 4a, 4b have a double function: they act as delivery rolls for removing the fibrous material B from the feed chute 1 and at the same time as feed rolls for feeding the fibrous material B to the high speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com