Cotton feed box adapted for blowing-carding process

A technology of blowing, carding and feeding cotton, applied in the field of cotton feeding box, can solve the problems of poor versatility and small application scope, and achieve the effect of good versatility and wide application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

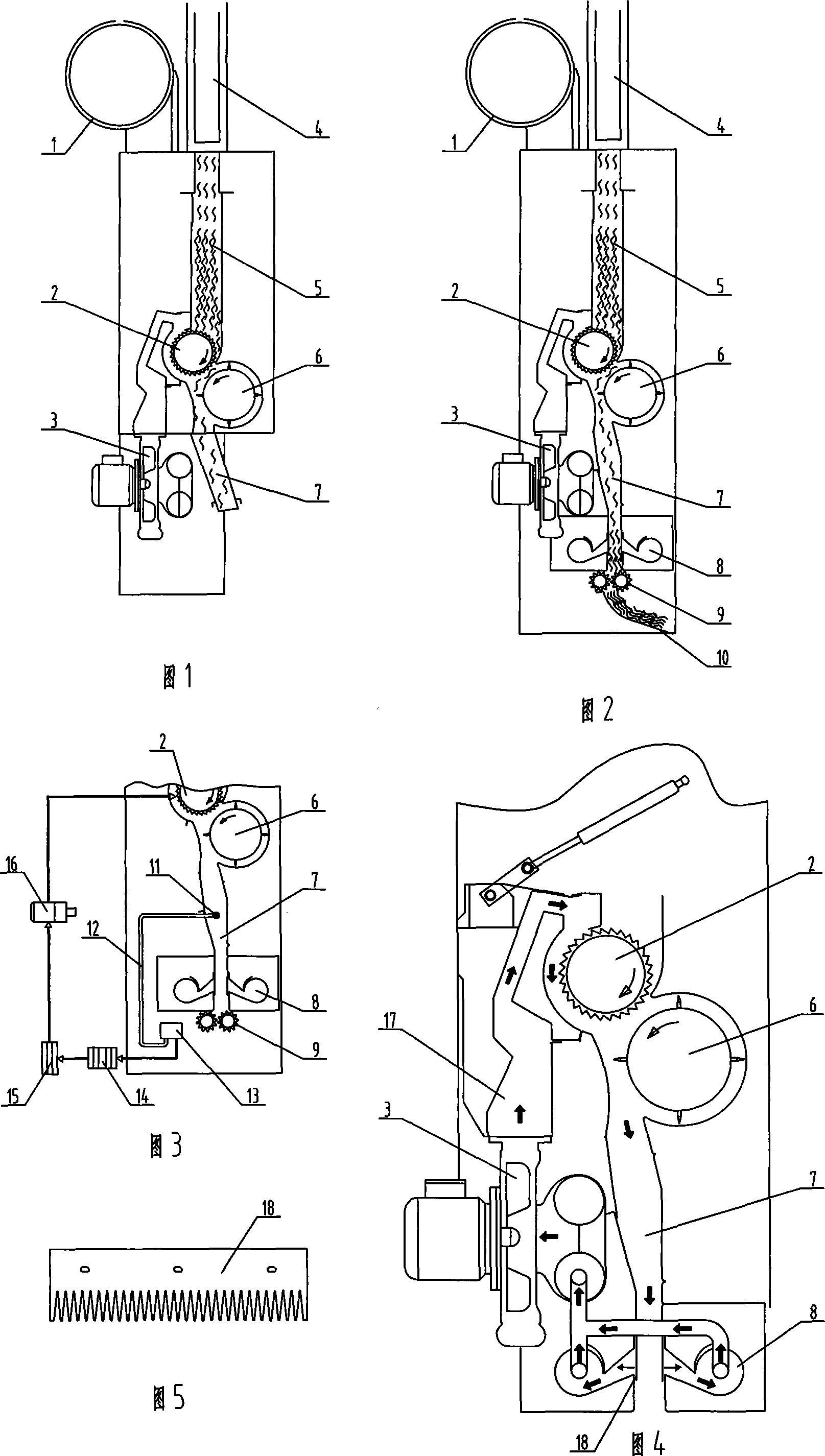

[0013] As shown in Figure 2, the cotton feeding box suitable for the blowing and carding process of the present invention includes a cotton feeding box body, a dust discharge pipeline 1 that is arranged above the cotton feeding box body and communicates with the inner cavity of the cotton feeding box through a pipeline, The cotton conveying pipeline 4 located above the cotton feeding box body is arranged in the cotton feeding box and its upper nozzle is connected with the lower nozzle of the cotton conveying pipeline 4, and the upper cotton road 5 is connected with the lower cotton road 7, And the feeding roller 2 and the opening beater 6 in the communication chamber between the upper cotton road 5 and the lower cotton road 7, the communication chamber is connected with the air supply port of the circulation fan 3 through the pipeline, and at the lower end of the lower cotton road 7 Both sides are provided with a pair of air return boxes 8, a pair of cotton outlet rollers 9 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com