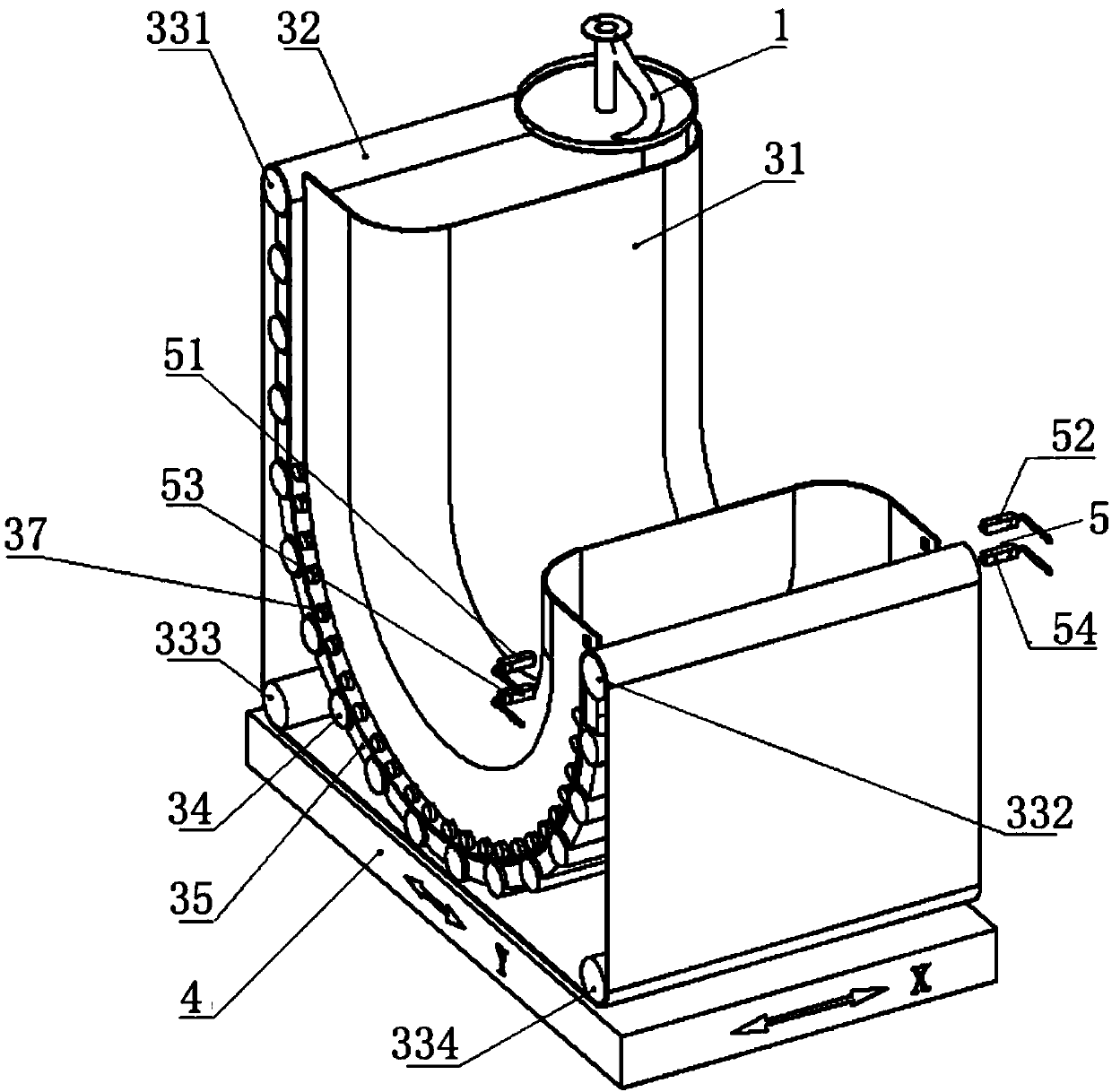

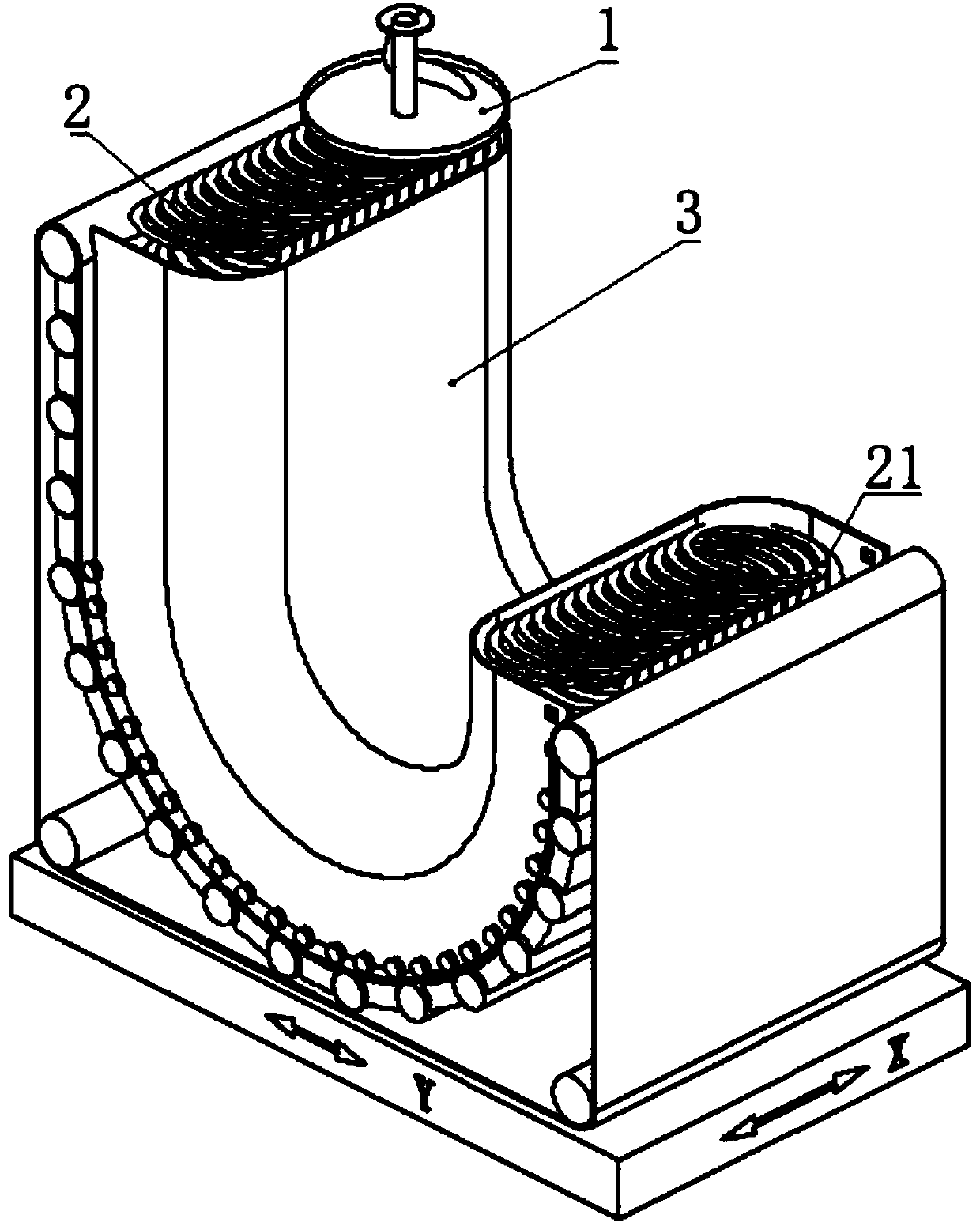

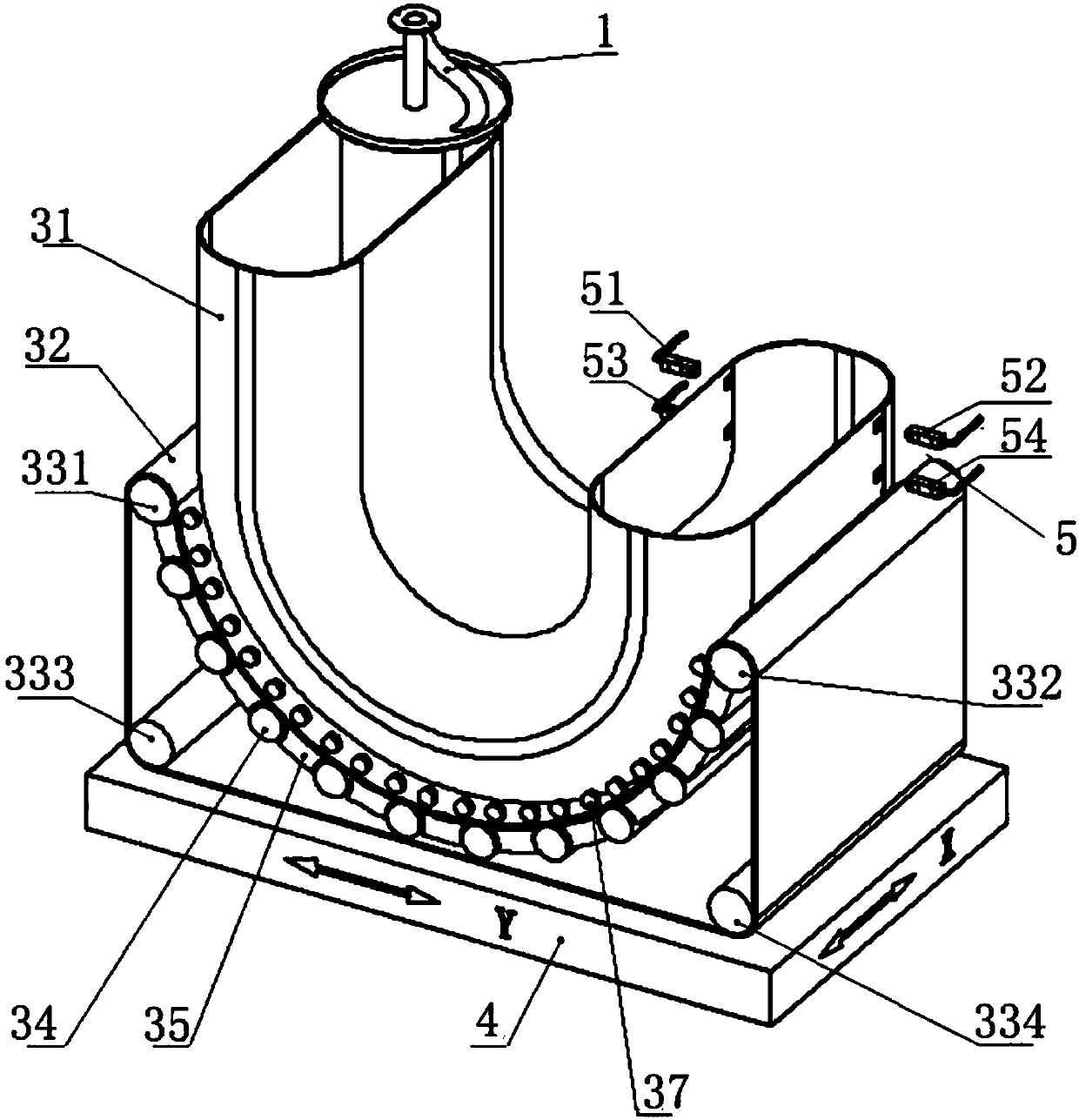

Non-slide fiber strip storage device with U-shaped bottom part

A storage device, technology for fiber strips in the fields of fiber handling, fiber feeding, textiles and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In Publication No. 1609291 "Method and Device for Dynamic Storage of Cotton Sliver", the disclosed technical solution is: "The cotton sliver output by the carding machine or the combing machine is stacked in a circular or oblong shape by the coiled sliver assembly. In the longitudinal section of the sliver reversing and dynamic reservoir adapted to the profile of the laminated sliver, the longitudinal section of the sliver reversing and dynamic reservoir is a "U"-shaped channel in which the sliver is placed After 180-degree inversion, it is dynamically stored in the sliver inversion and dynamic storage, and the head end of the ring-shaped laminated sliver can be drawn out of the sliver dynamic storage without interruption."

[0023] One of the matching forms is: "the self-rotating sliver (the upper part of the ordinary coiler) and the sliver inverting and dynamic storage with a long circular cross-section and a "U"-shaped pipe in the longitudinal section, the sliver inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com