Cashmere carding combination machine

A combined machine and separating and thinning technology, which is applied in the direction of opening and blowing combined machines, deburring devices, textiles and papermaking, etc., can solve the problems of low carding efficiency, high fiber damage and waste of separating and thinning machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

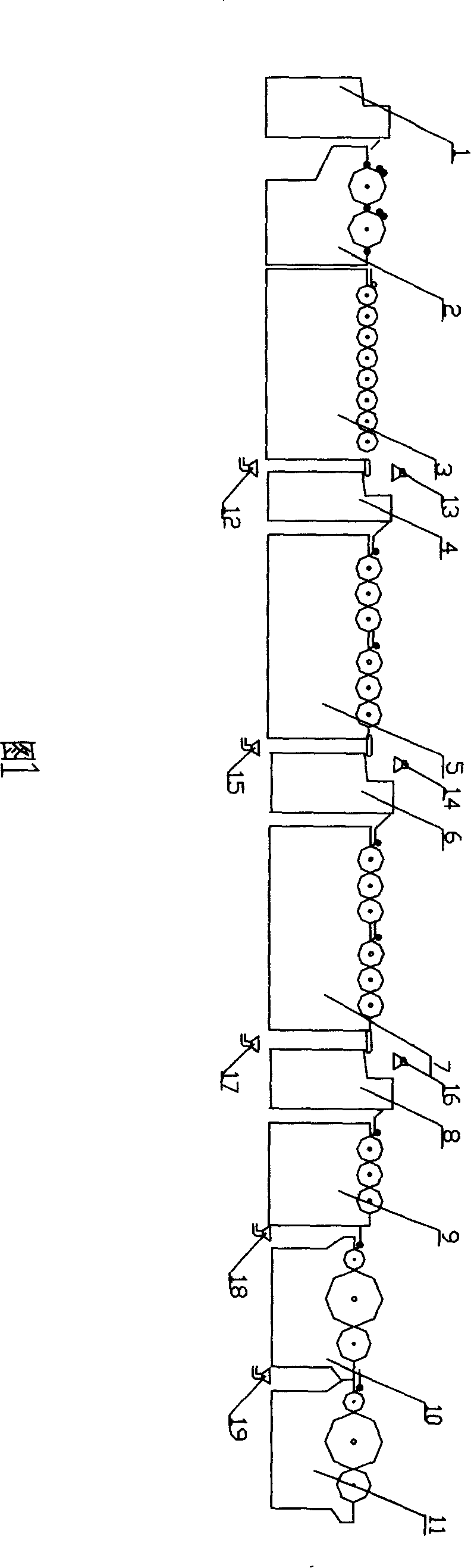

[0011] The combined cashmere separating and thinning machine shown in Figure 1 is a combined equipment composed of a wool feeding machine, a roughing machine and a carding machine. 3. Wool feeding machine 4, roughing machine 5, wool feeding machine 6, roughing machine 7, wool feeding machine 8, roughing machine 9, carding machine 10, carding machine 11, the assembly line combination of the above equipment, wool feeding The bottom of the machine 4 is provided with a receiving hopper 12, the feeding port of the wool feeding machine 4 is provided with a blanking port 13, the bottom of the wool feeding machine 6 is provided with a receiving hopper 15, and the 6 feeding ports of the wool feeding machine are provided with a blanking port 14, and the feeding port of the wool feeding machine is provided with a blanking port 14. The bottom of the machine 8 is provided with a receiving hopper 17, the feeding port of the wool feeding machine 8 is provided with a blanking port 16, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com