Production method of nonwoven fibrics

A production method and technology of non-woven fabrics, applied in the direction of non-woven fabrics, textiles, papermaking, adhesives, etc., can solve the problems of uneven fiber nodding, many mechanical failures, and narrow width of non-woven fabrics, and achieve simple mechanical structure , Improve yield rate, good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

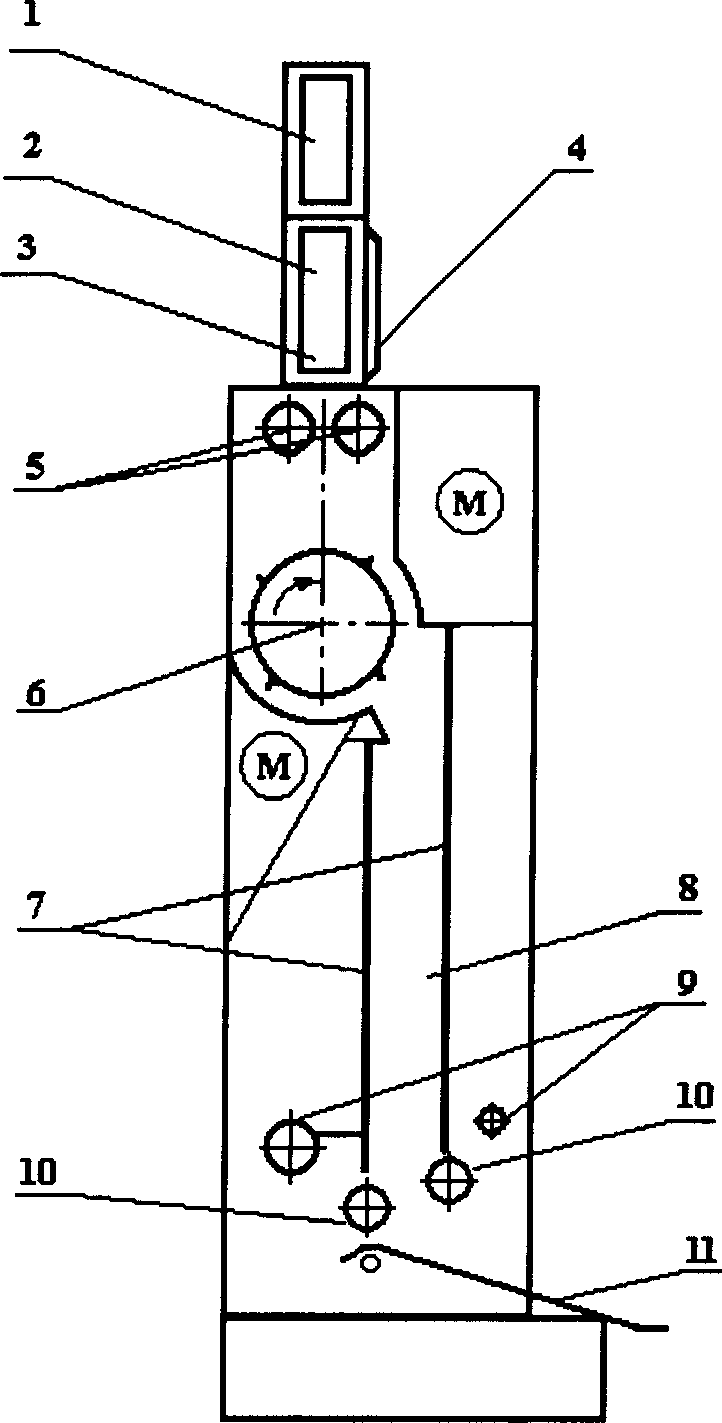

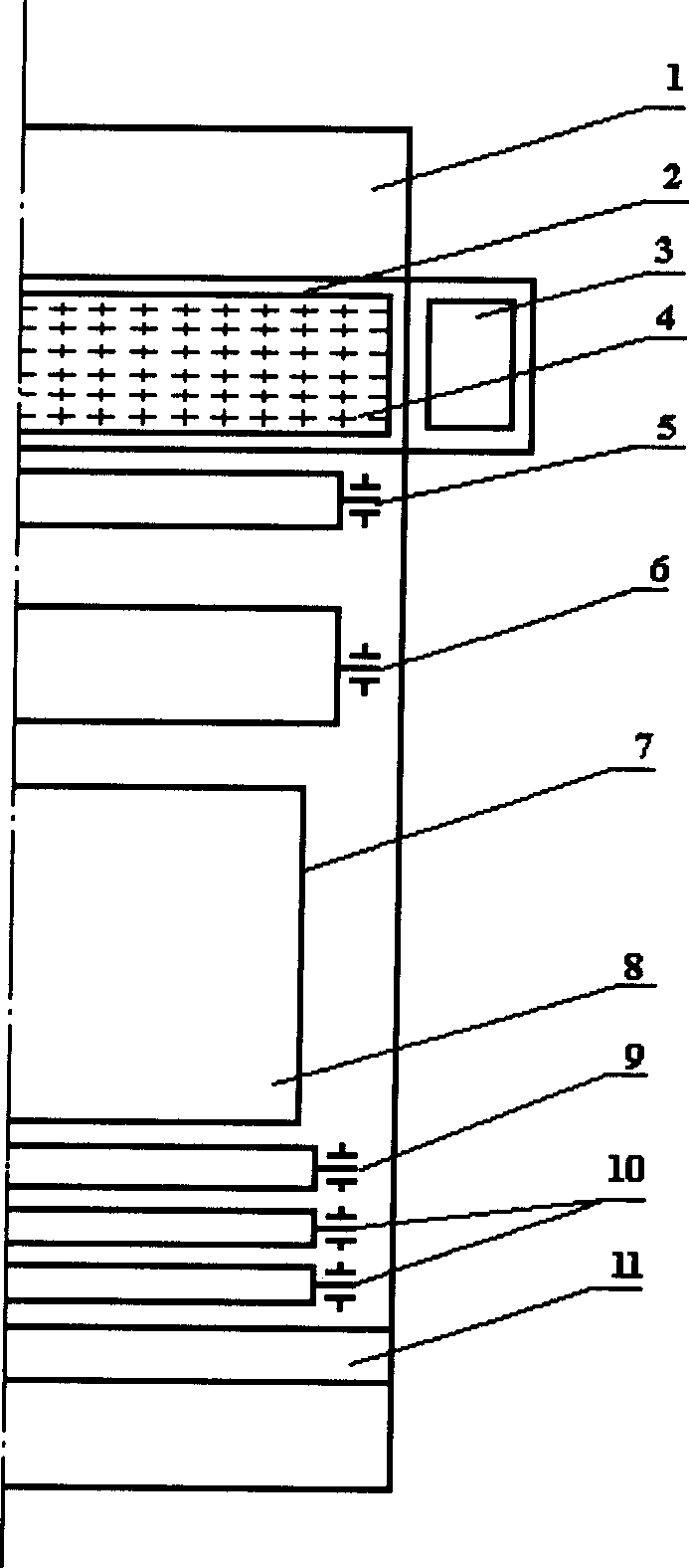

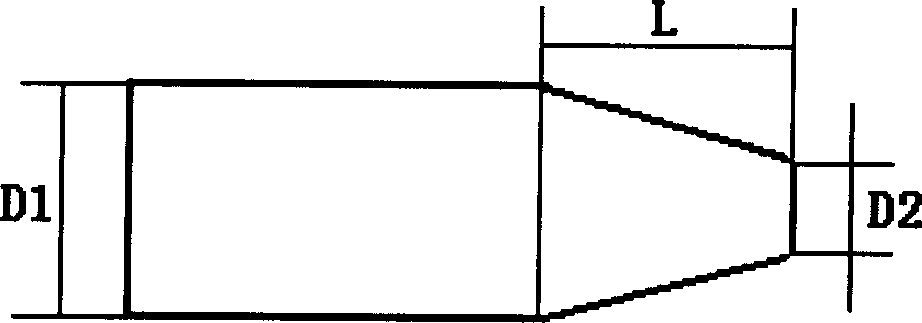

Embodiment 1

[0020] The polypropylene fiber is opened by the cotton opener, and is directly transported to the cotton feeding box in the airflow mode, and the cotton feeding box adopts the present invention figure 1 The fiber is supplied to the carding machine, and after carding, web laying, recycling knife trimming, hot pressing turbine hot rolling forming, coiler coiling non-woven fabric, and finally slitting machine slitting to obtain non-woven fabric products. Among them, the adjustable exhaust plate 4 has dense small holes at both ends, no holes in the middle, the maximum diameter of the small holes is 3 cm, and the fiber uniform distributor is installed in the forward direction. image 3 The orifice nozzle, D 1 / D 2 =10,L / D 2 for 4. For the production device with a width of 200 cm feeding box, the production rate is 17 g / m 2 The process conditions and product quality of non-woven fabrics are shown in Table 1.

Embodiment 2

[0024] The polypropylene fiber is opened by the cotton opener, and is directly transported to the cotton feeding box in the airflow mode, and the cotton feeding box adopts the present invention figure 1The fiber is supplied to the carding machine, and after carding, web laying, recycling knife trimming, hot pressing turbine hot rolling forming, coiler coiling non-woven fabric, and finally slitting machine slitting to obtain non-woven fabric products. Among them, the adjustable exhaust plate 4 has dense small holes at both ends, no holes in the middle, and the maximum diameter of the small holes is 2 cm. image 3 The orifice nozzle, D 1 / D 2 =8,L / D 2 = 2, for the production device with a width of 200 cm feeding the cotton box, the production is 20 g / m 2 The process conditions and product quality of non-woven fabrics are shown in Table 1.

Embodiment 3

[0028] The polypropylene fiber is opened by the cotton opener, and is directly transported to the cotton feeding box in the airflow mode, and the cotton feeding box adopts the present invention figure 1 The fiber is supplied to the carding machine, and after carding, web laying, recycling knife trimming, hot pressing turbine hot rolling forming, coiler coiling non-woven fabric, and finally slitting machine slitting to obtain non-woven fabric products. Among them, the adjustable exhaust plate 4, the cross holes at both ends are dense, the middle is sparse, the maximum diameter of the cross holes is 5 cm, and the fiber uniform distributor is installed in the forward direction image 3 The orifice nozzle, D 1 / D 2 =12,L / D 2 =6, for the production device with a width of 200 cm feeding the cotton box, the production is 25 g / m 2 The process conditions and product quality of non-woven fabrics are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com