Apparatus on a flat card or roller card for setting the working spacing between the cylinder and at least one neighbouring roller

A carding machine and equipment technology, applied in fiber processing, textiles and papermaking, deburring devices, etc., can solve problems such as roller contact with working components, achieve fast closed-loop and open-loop control, flexible response to state changes, and rapid response to state changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

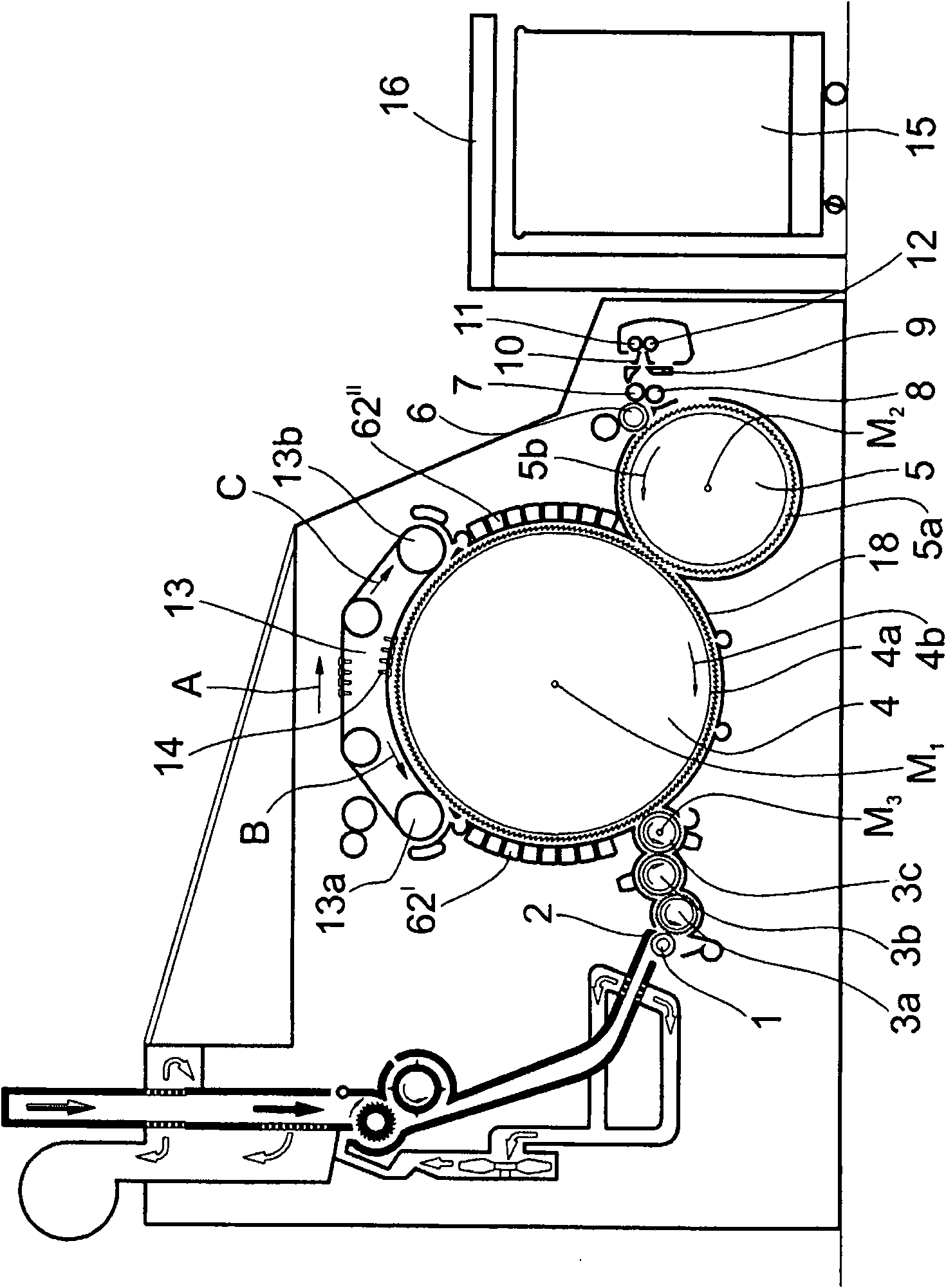

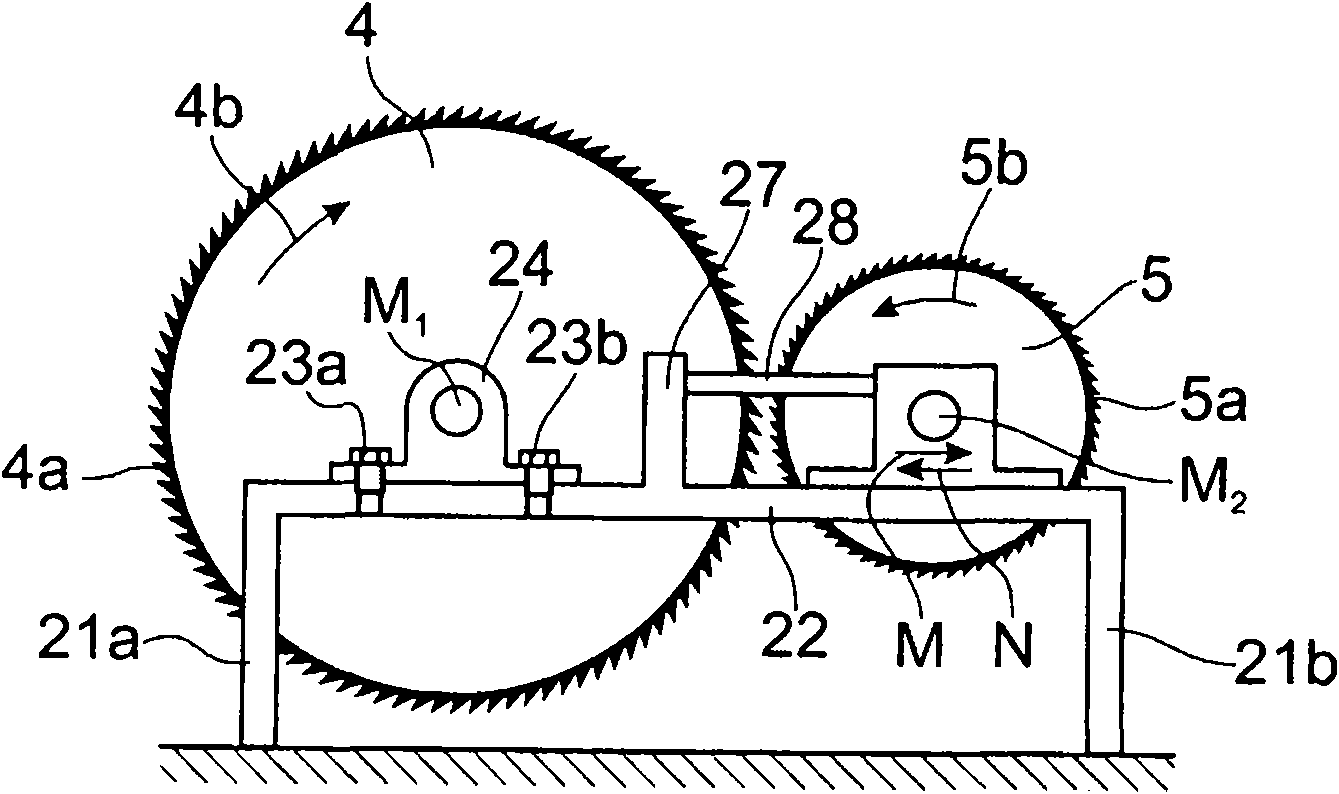

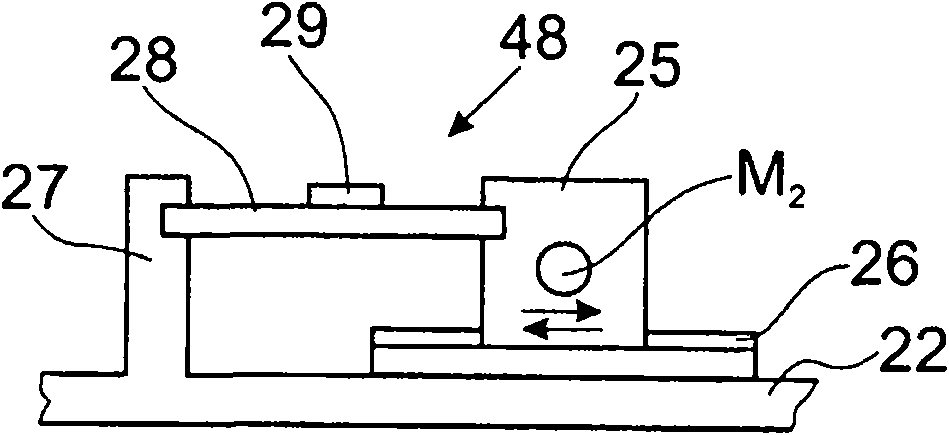

[0031] attached figure 1 Shown is a carding machine, for example a Trufischer (Trützschler) flat carding machine TC07, said carding machine has a feed roller 1, feed plate 2, licker-in rollers 3a, 3b, 3c, cylinder 4. Doffer 5, Cotton Stripping Roller 6, Clamping Roller 7, 8, Cotton Web Guide 9, Bar Guide Horn 10, Conveying Roller 11, 12, Cotton Guide Roller 13a, 13b with card top Rotating carded sliver 13, carding flat 14, can 15 and coiler 16. The direction of roller rotation is indicated by the curved arrow. Reference sign M 1 Indicates the center point (axis) of cylinder 4, reference sign M 2 Represents the center point of the doffer 5, reference sign M 3 Indicates the center point of the licker-in roller 3c. Reference numeral 4a designates the card clothing, and reference numeral 4b designates the direction of rotation of the cylinder 4 . Reference numeral 5a designates a card clothing, and reference numeral 5b designates the direction of rotation of the doffer. Ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com