A method for predicting NOx emission concentration in SCR system based on time delay estimation

A technology of SCR system and emission concentration, which is applied in the field of NOx emission concentration prediction of SCR system based on time delay estimation, which can solve the problems of lag in concentration measurement, complex reaction process and inaccuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

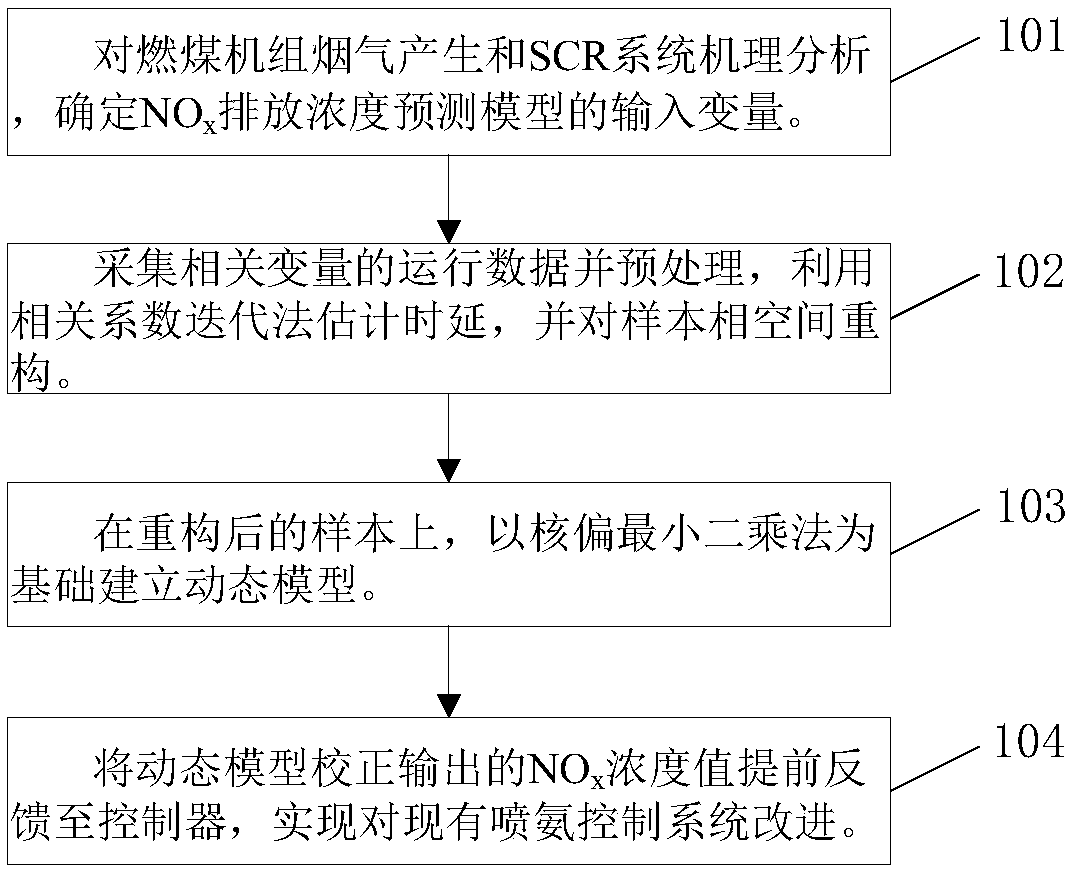

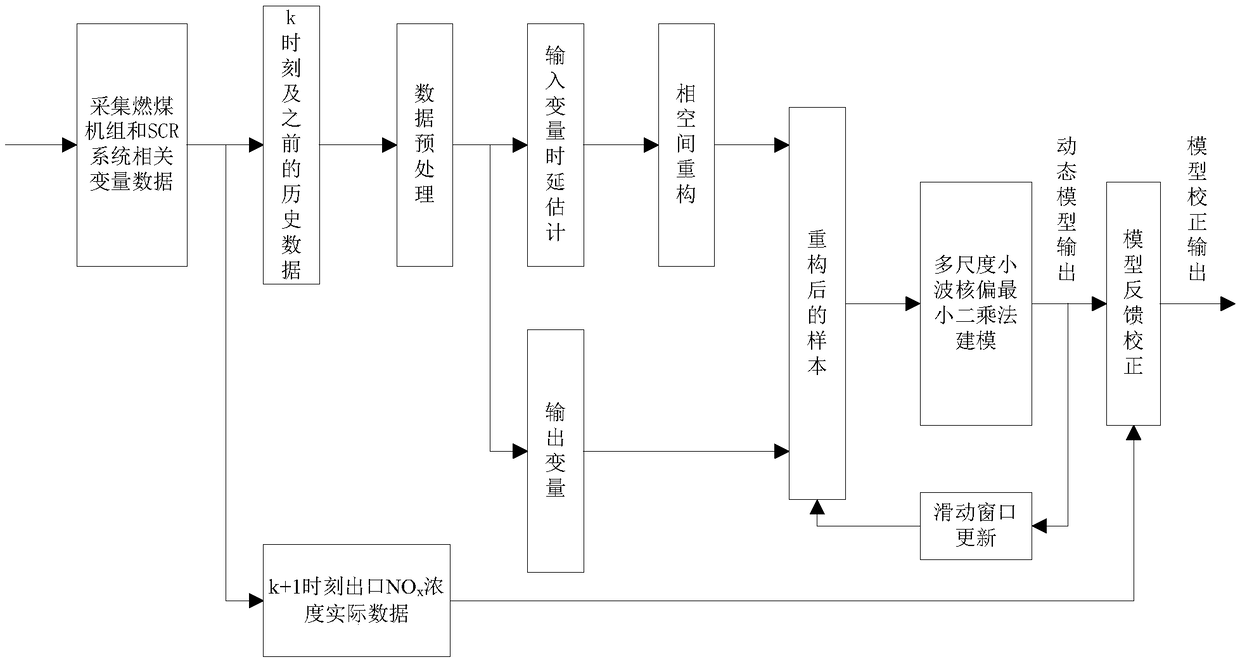

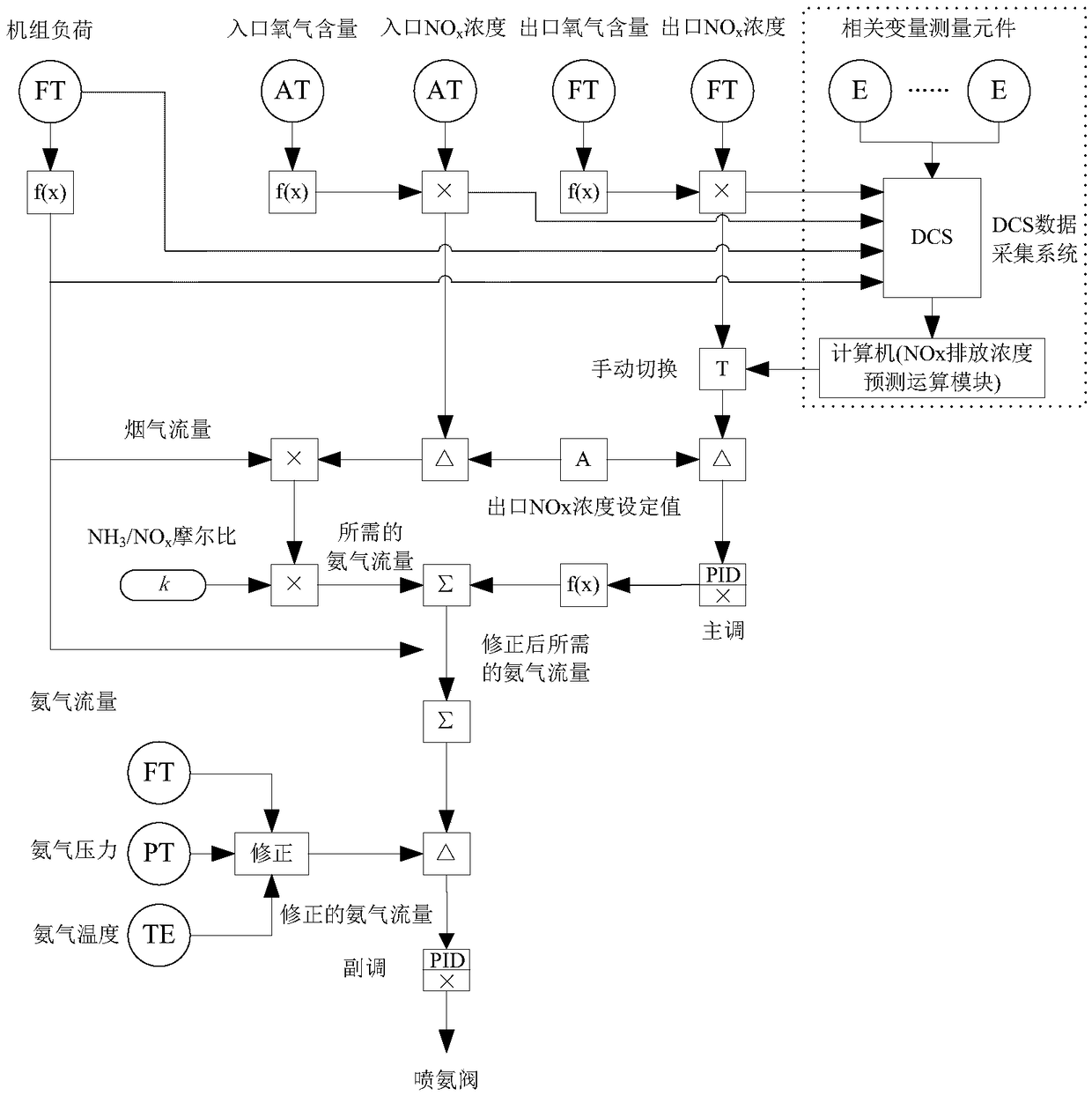

[0057] Such as Figure 1-2 As shown, the delay estimation-based SCR system NO described in the embodiment of the present invention x The emission concentration prediction method, through the analysis of the flue gas generation of coal-fired units and the mechanism of the SCR system, determines the NO x input variables for emission concentration prediction models; in order to reduce system hysteresis and NO x Measure the influence of time delay, collect the operating data of related variables, use the correlation coefficient iterative method to estimate the time delay of the input variable, and reconstruct the phase space of the sample; on the basis of the reconstructed sample, use the kernel partial least square method to establish the NO x Emission concentration prediction model to improve the accuracy of the prediction mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com