Dynamic capacity increasing method for oil-immersed transformer

An oil-immersed transformer and dynamic capacity-increasing technology, which is applied in the field of transformers, can solve problems such as unfavorable expansion of substation intelligent control and intelligent management, failure to consider the influence of ambient temperature cooling effect, and inability to satisfy the dynamic control of transformers, etc., to achieve reduction Continuous working time, energy-saving operation, and overheating prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings.

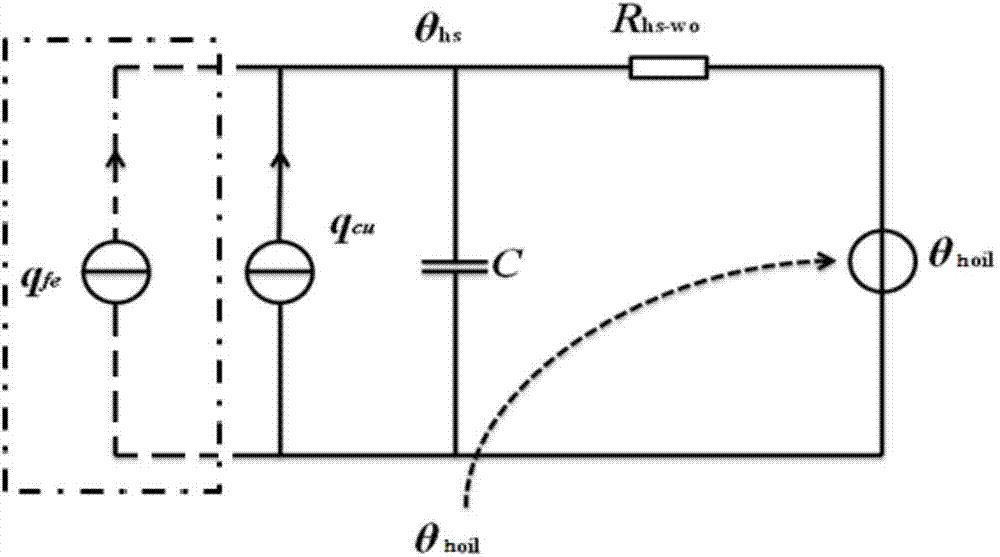

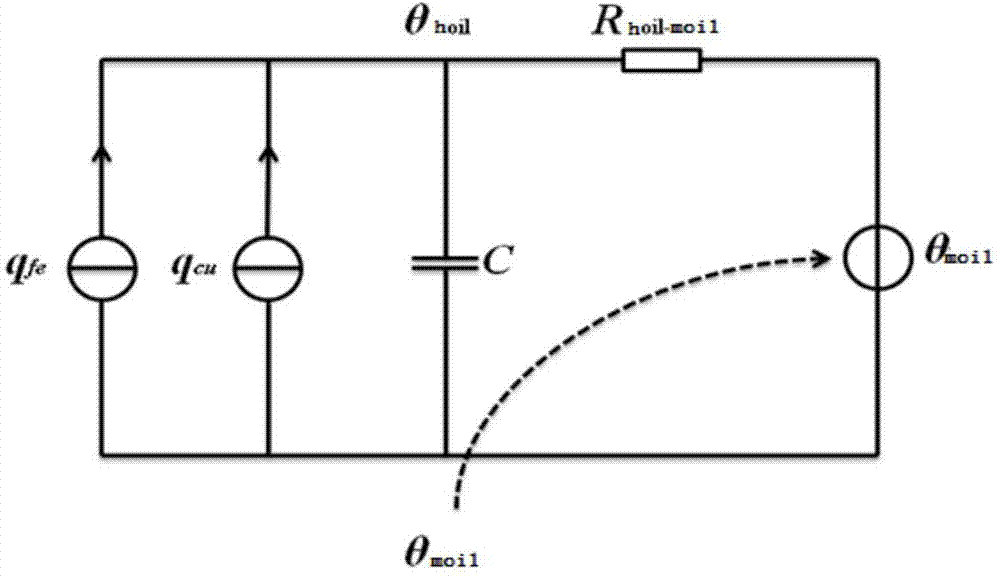

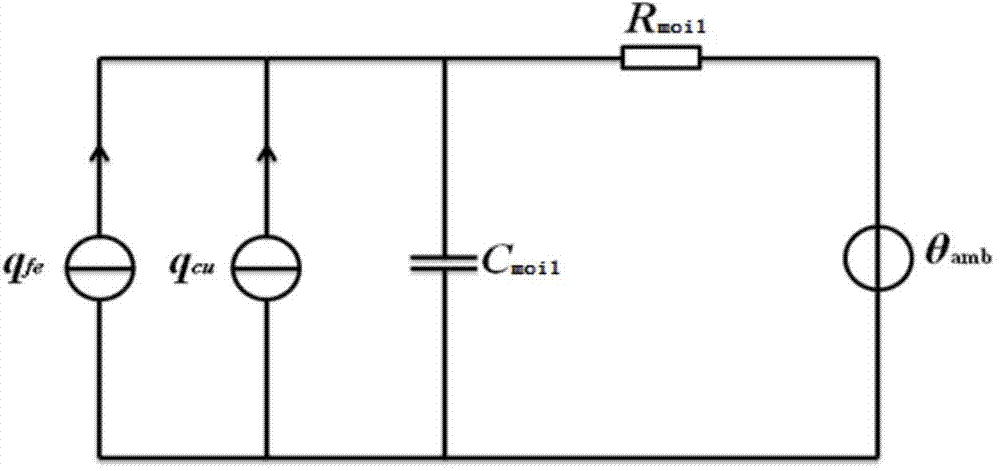

[0070] Figure 1~3 Among them, the improved thermal circuit model of the transformer of the present invention is composed of three sub-thermal circuit models, which are sequentially from top to bottom: the thermal circuit model of the winding hot spot to the top layer oil temperature, the thermal circuit model of the top layer oil to the average oil temperature, and the shell to the ambient temperature Thermal model.

[0071] The node temperature value obtained in the next model can be regarded as the ambient temperature of the previous model, and so on, and finally the hot spot temperature of the winding can be obtained.

[0072] The parameters in each model are adjusted as follows:

[0073] Table 1. Calculation parameter table

[0074]

[0075] Among them, R y is the thermal resistance, C y is the heat capacity, the subscript hs-oil in the parameter indicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com