Online recursive calculation method for fume occurrence rate of metallurgical furnace

A calculation method and technology of occurrence rate, which can be used in computing, manufacturing computing systems, data processing applications, etc., and can solve the problems of untimely calculation and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] In the following, the present invention will be further described in detail with reference to implementation examples:

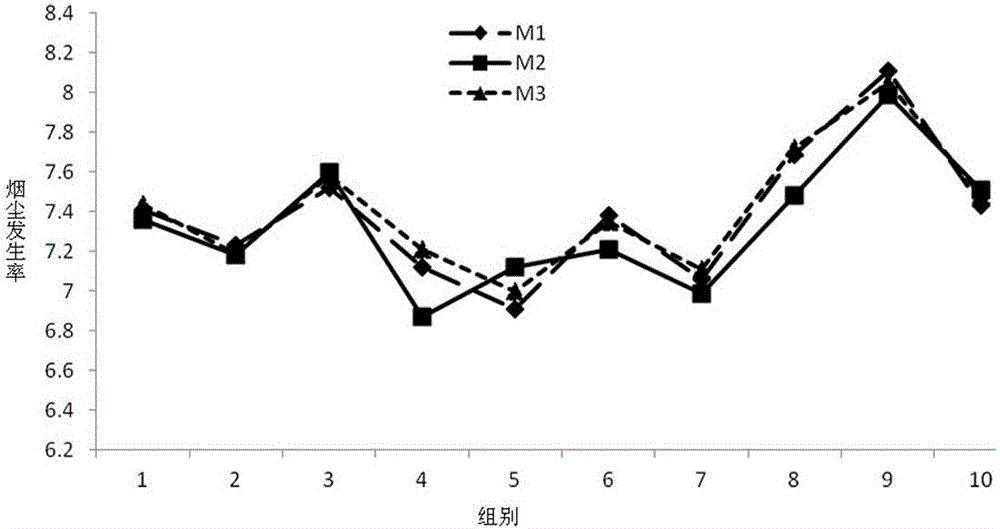

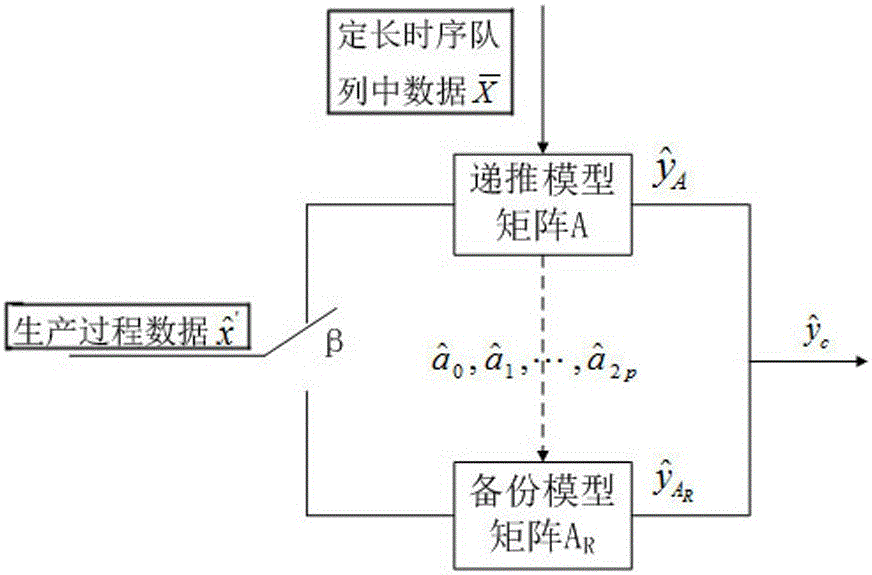

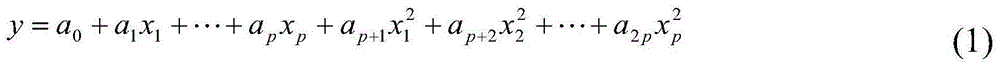

[0093] Taking the flash smelting furnace used for copper enrichment as an example, the smoke and dust generated during the smelting process are mainly mixed with the amount of copper concentrate, the amount of slag concentrate, the amount of slagging flux quartz sand, the unit consumption of oxygen, the amount of slag produced, and the production It is related to the amount of copper matte. Therefore, the soot incidence regression fitting model has a total of 12 independent variables, of which the main independent variable is selected to enter the furnace to mix copper concentrate, slag concentrate, slagging flux, quartz sand, oxygen consumption, slag produced, and copper matte produced There are 6 in total. In order to improve the accuracy of model prediction, the corresponding 6 augmented independent variables are obtained by nonlinear transformation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com