Online prediction method for crossbeam loading speed of large-sized die forging press based on Taylor expansion

A technology of die forging press and prediction method, applied in the field of forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061]The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

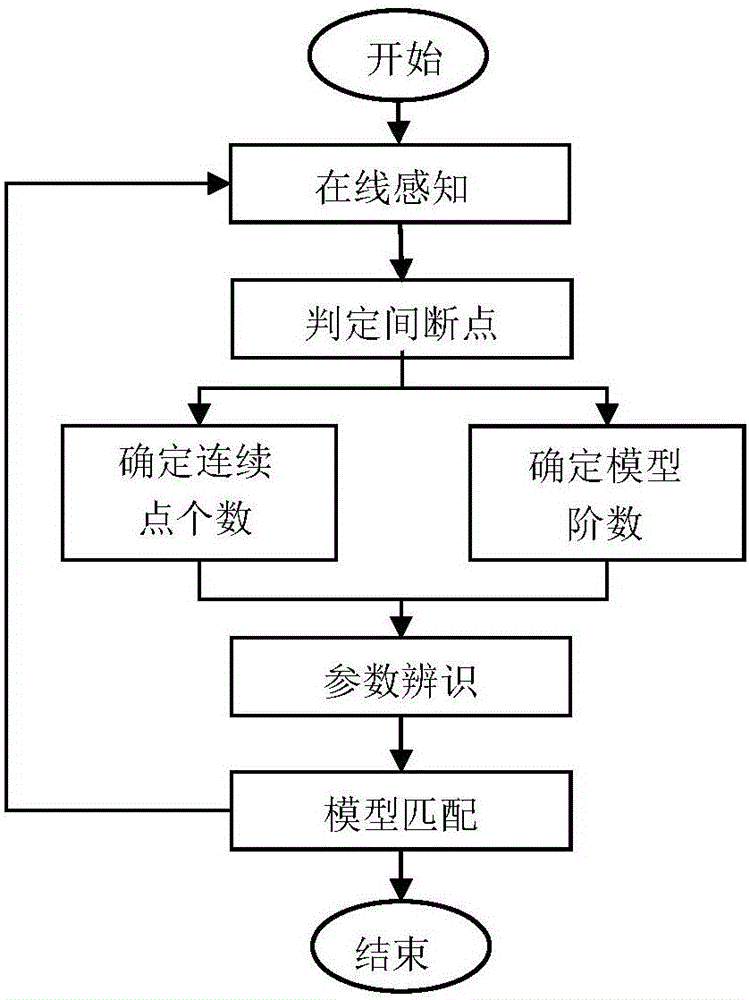

[0062] The present invention is an online prediction method of beam speed on a large die forging press, the flow chart of which is as follows figure 1 shown. Taking the forging process of an aluminum alloy (Al-1100) forging as an example, the implementation details of the online prediction of the beam speed on the large-scale die forging press related to the present invention are introduced in detail. The method includes:

[0063] Step 1: Predict the speed of the upper beam at the next moment based on the online perception of the load of the large die forging press (system input) and the speed of the upper beam (system output) during the forging process;

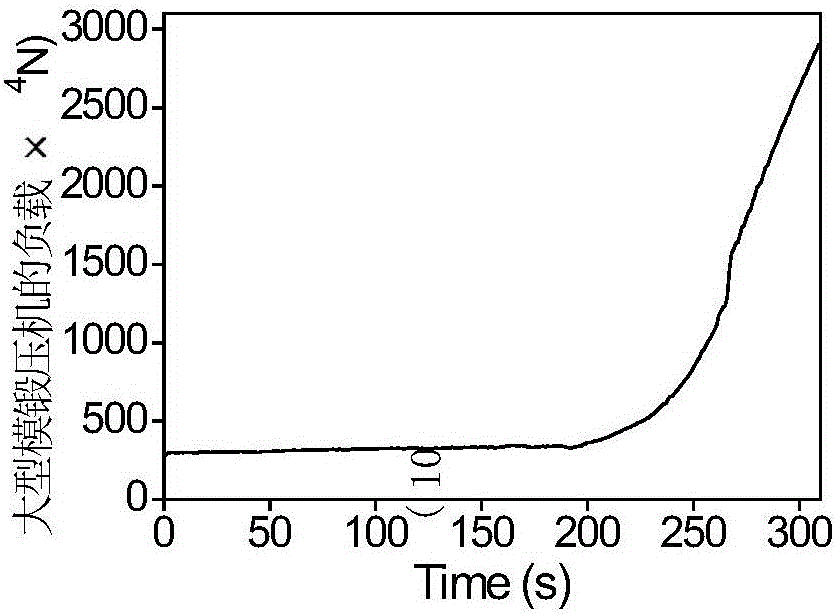

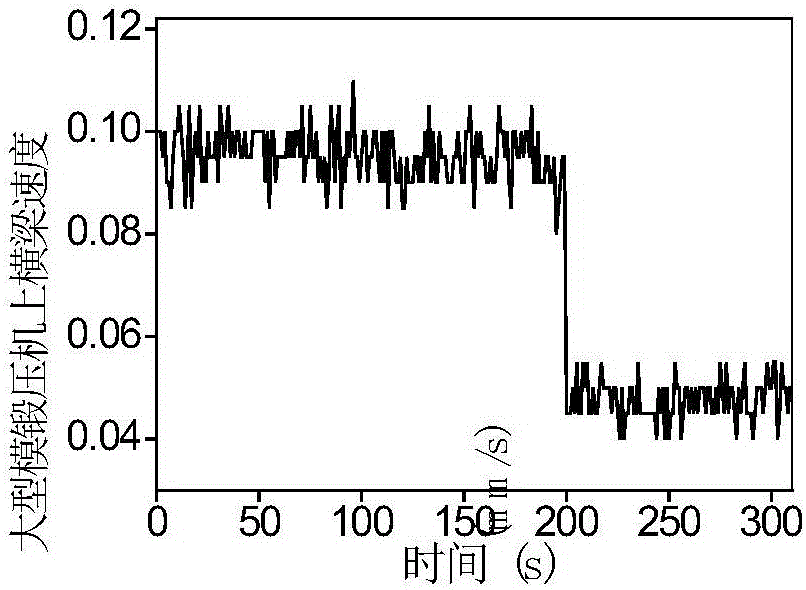

[0064] A forging test was carried out on an aluminum alloy (Al-1100) forging, and the load of a large die forging press during the forging process (such as figure 2 shown) and the upper b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com