Junction temperature prediction method of IGBT module for driver

A prediction method and driver technology, applied in neural learning methods, biological neural network models, neural architectures, etc., can solve problems such as junction temperature cannot be directly measured

- Summary

- Abstract

- Description

- Claims

- Application Information

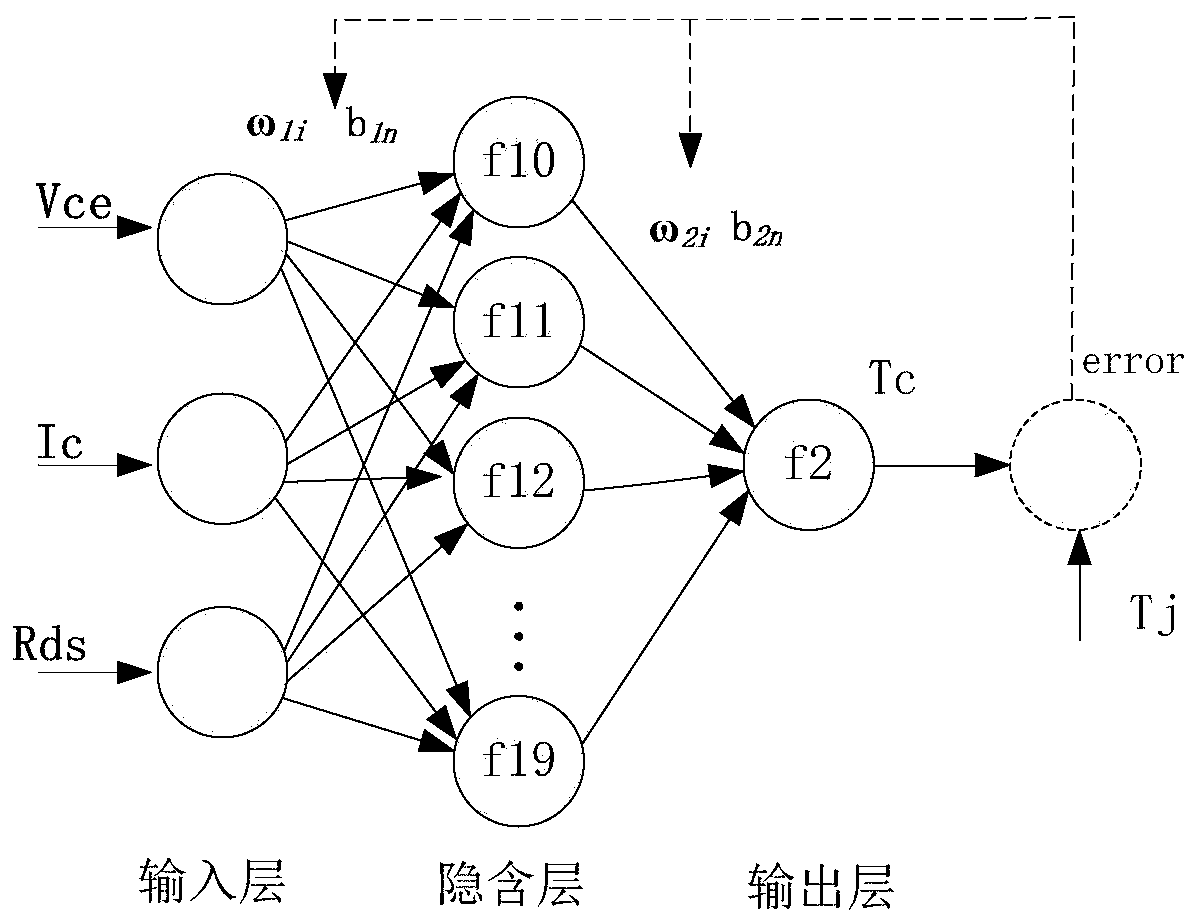

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

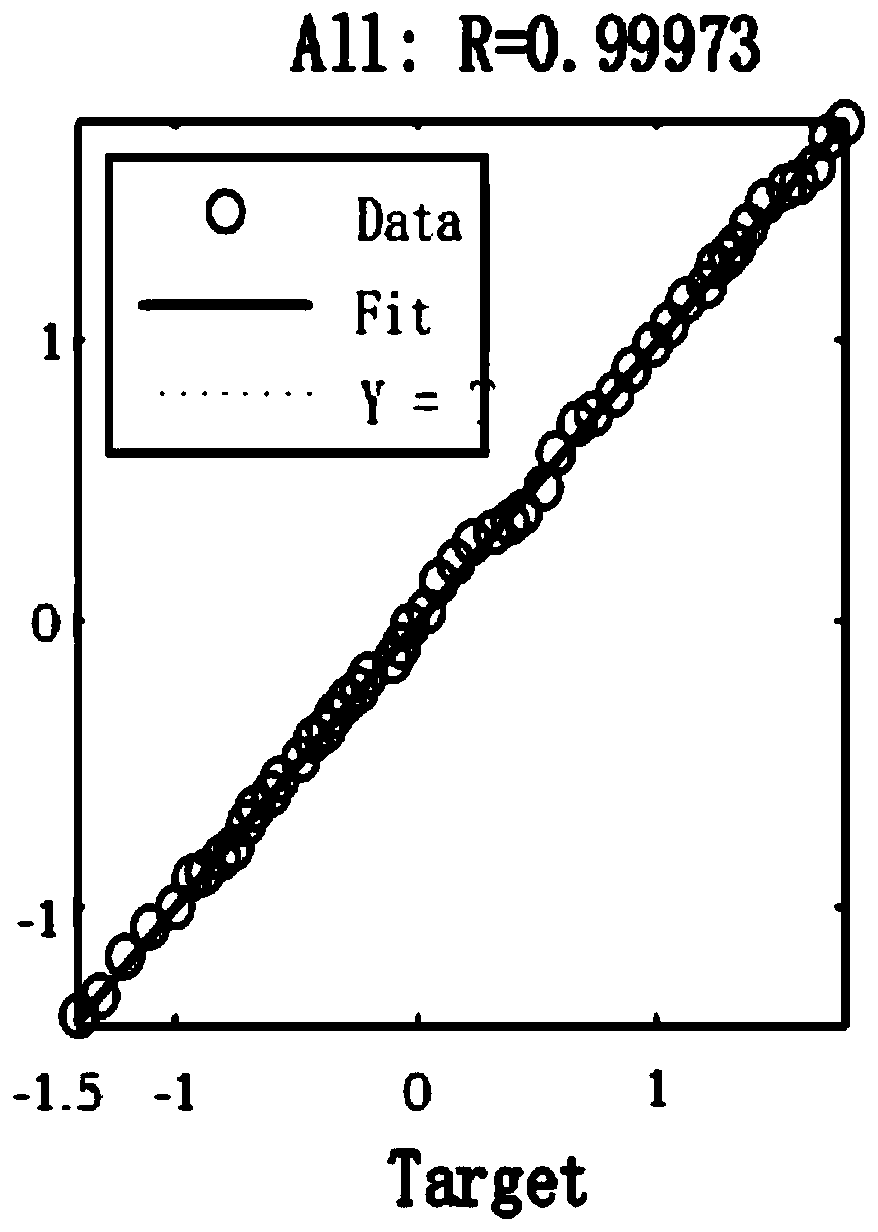

[0036] Taking the 3300V / 200A IGBT module driver of the model FF200R33KF2C produced by Infineon as an example, the junction temperature prediction method of the IGBT module for the driver of the present invention is used to predict the junction temperature. Specific steps include:

[0037] Step 1. Sampling the 3300V / 200A IGBT module driver of the model FF200R33KF2C produced by Infineon, and divide the sampling data into training group data and test group data according to 3:1; the test group data is used to verify the correctness of the prediction results of this method ;

[0038] The specific sampling method is as follows: the DC power supply has set the current value Ic, and the DC value is taken as a value within the range of [1,75], and the value is changed by interval sampling, and then the IGBT module driver is powered on, and the trigger pulse signal is pressed. The IGBT module driver is turned on, the saturation voltage drop Vce is measured, and the corresponding colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com