Predicating method for TLE (transfer line exchanger) outlet temperatures and operation cycles of ethylene cracking furnaces

An ethylene cracking furnace and outlet temperature technology, which is applied in the directions of cracking, hydrocarbon cracking to hydrocarbon production, and non-catalytic thermal cracking to achieve the effects of overcoming external disturbances, realizing online updates, and overcoming model mismatches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

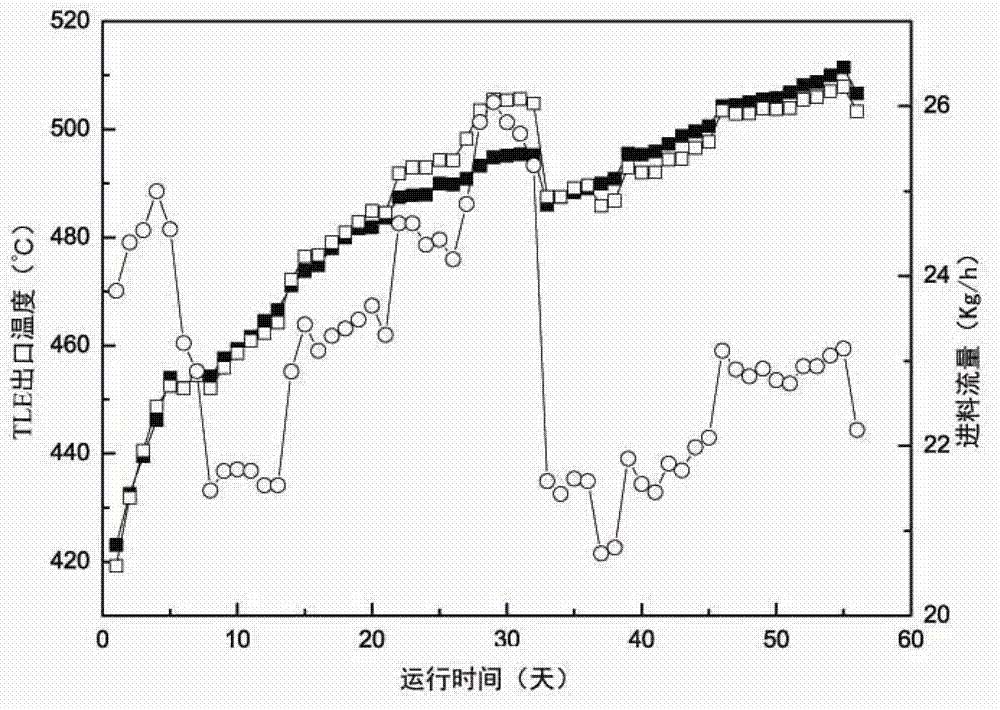

[0032] The prediction of the outlet temperature and operation period of the industrial ethylene cracking furnace TLE in this specific embodiment is based on the cracking of naphtha as an example, but it is not limited thereto.

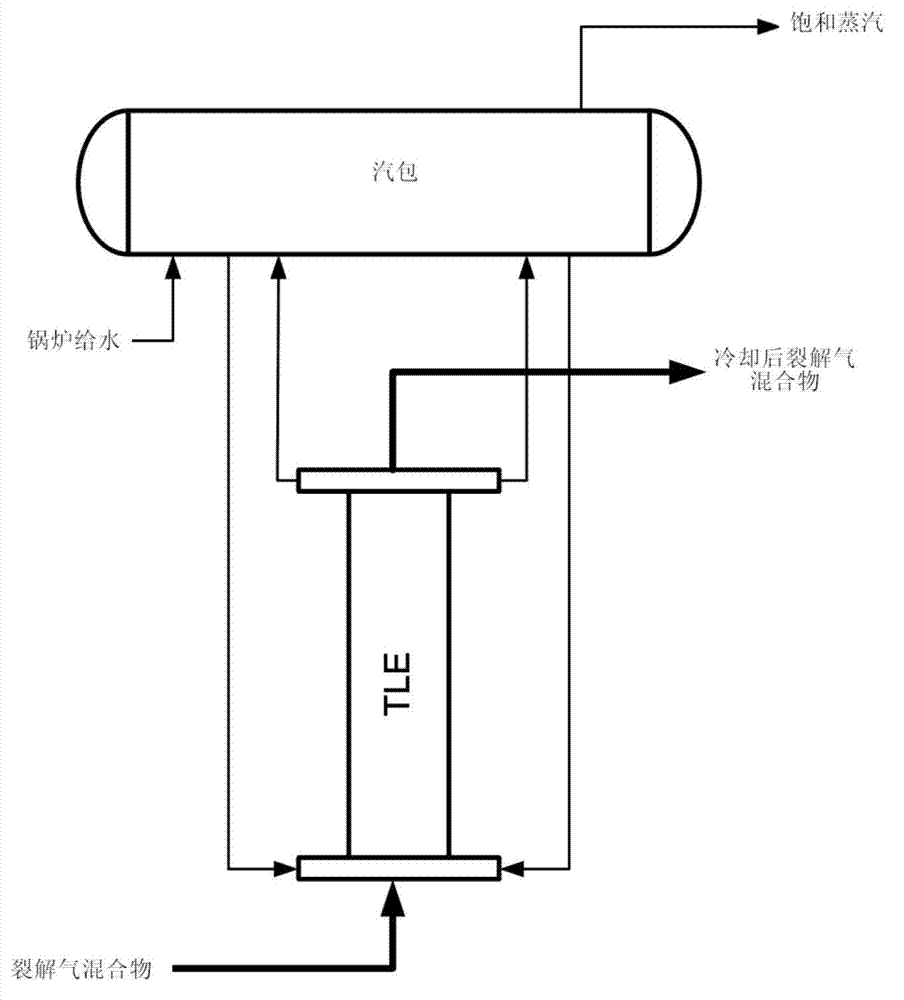

[0033] The industrial cracking furnace TLE system of this concrete example is as figure 1 As shown, it contains multiple parallel TLEs and a steam drum. In the tube side of the TLE, the high-temperature mixed cracked gas from the radiant section of the cracking furnace passes through, where the high-temperature cracked gas is quickly cooled to a certain temperature to reduce the secondary reaction of the high-temperature cracked gas and ensure the target product yield; after passing through the cracking furnace The boiler feed water preheated in the convection section is sent to the steam drum to supplement the heat exchange fluid in the steam drum; through the principle of thermosiphon, the saturated water in the steam drum sinks to the shell side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com