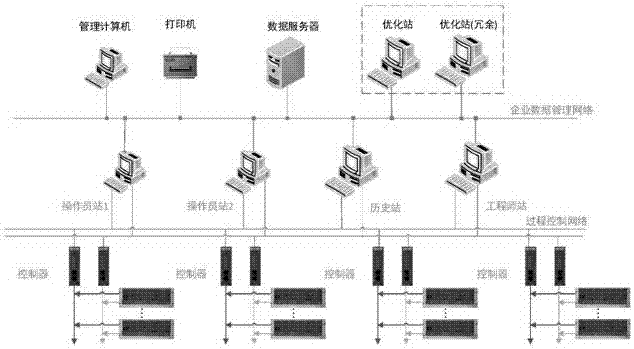

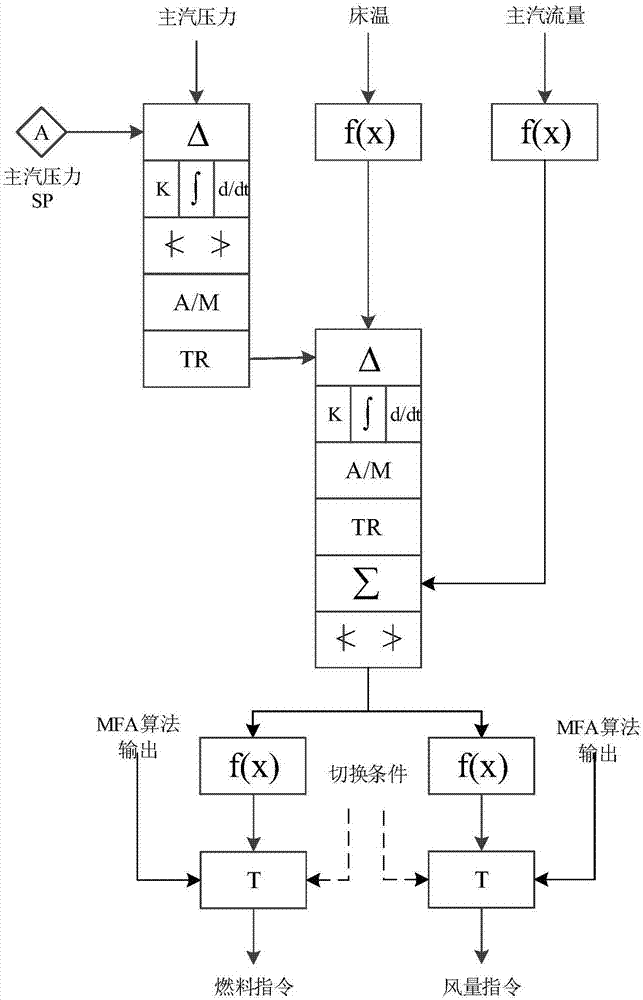

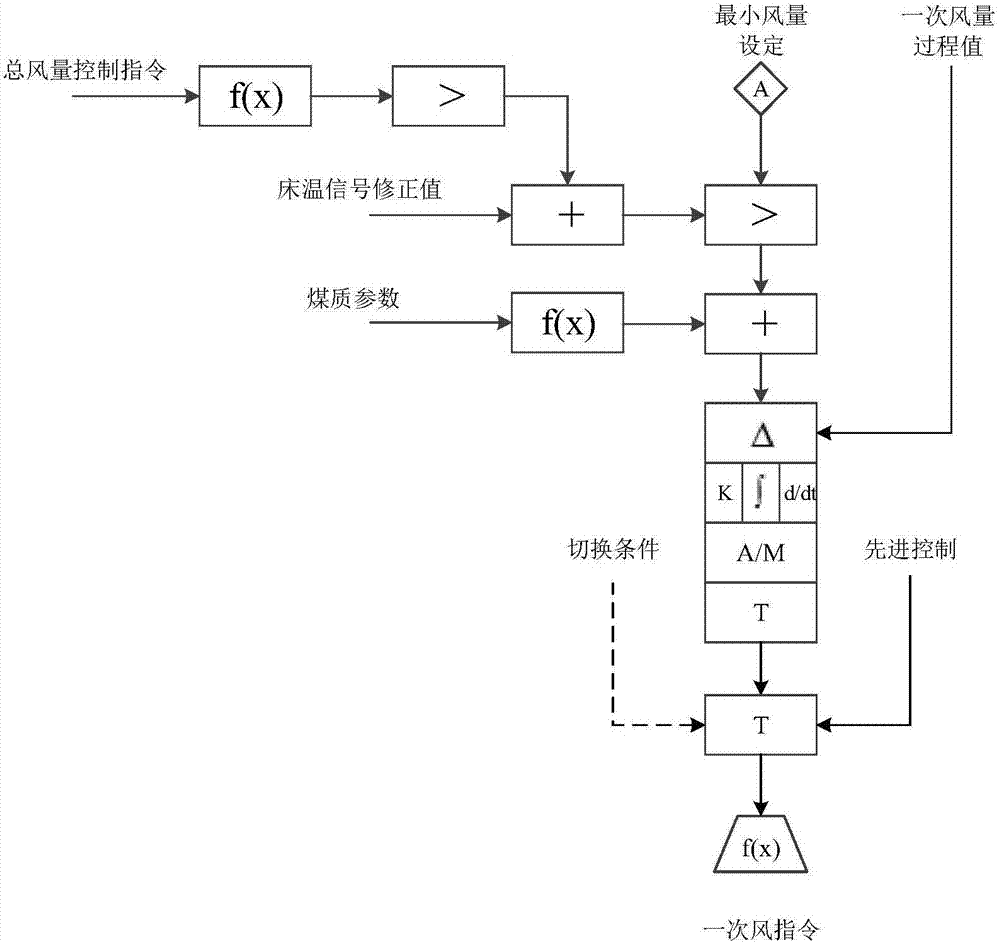

Fluidized bed boiler control and combustion optimization system

A fluidized bed boiler, combustion optimization technology, applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, combustion method, etc., can solve the problem of difficult control of the boiler system, and achieve the effect of improving control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] The #3 boiler of a power plant, the existing equipment status: the boiler model is DG483 / 13.7-II1, which is a 483t / h circulating fluidized bed boiler designed and manufactured by Dongfang Boiler Factory. The boiler is mainly composed of a membrane water-cooled hearth, two steam-cooled cyclone separators and a rear shaft (HRA) covered by a steam-cooled wall.

[0145] The model of the high-pressure vulcanization fan is L925WDB, the quantity is 2 sets, and the medium flow rate is 282m 3 / min, the maximum pressure difference of the working medium is 58.8kPa, the spindle speed is 780r / min, the motor model is YKK-5001-8, the motor voltage is 6000V, the motor current is 51.3A, the motor power is 400kW, and the motor speed is 745r / min; The model is VZ41-2950F / S1, the quantity is 2 sets, and the medium flow rate is 488604Nm 3 / h, full pressure 11252Pa, speed 985r / min, equipped motor model is YSPKK710-6, motor voltage 6000V, motor current 237A, motor power 2000kW, motor speed 99...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com