Multi-period intermittent process soft measurement modeling method based on FF-RVM

A modeling method and soft-sensing technology, applied in character and pattern recognition, instrumentation, design optimization/simulation, etc., can solve problems that are difficult to meet the data volume requirements of soft-sensing modeling, reduce the online prediction accuracy of quality variables, and predict soft-sensing models poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

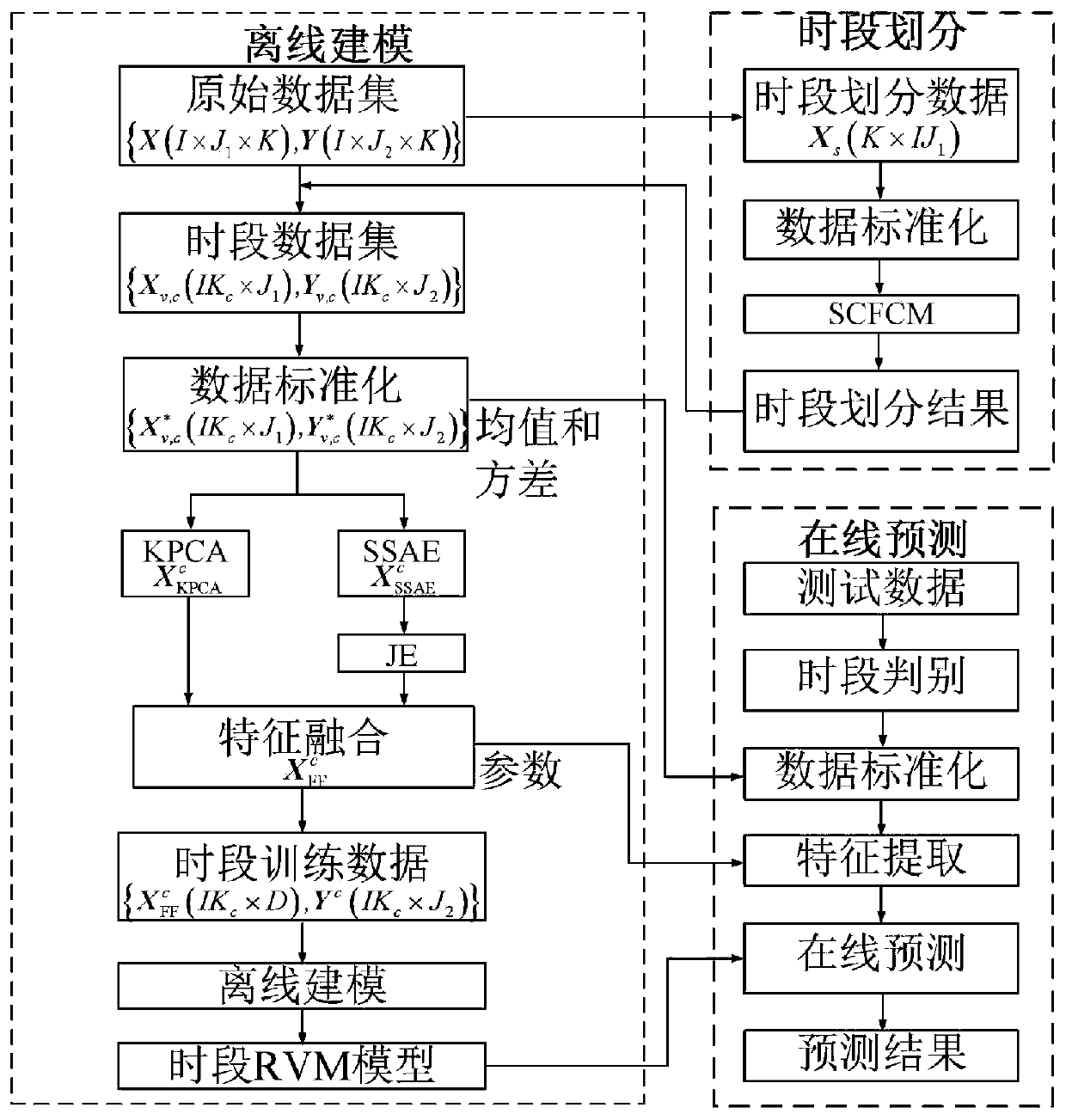

Method used

Image

Examples

Embodiment

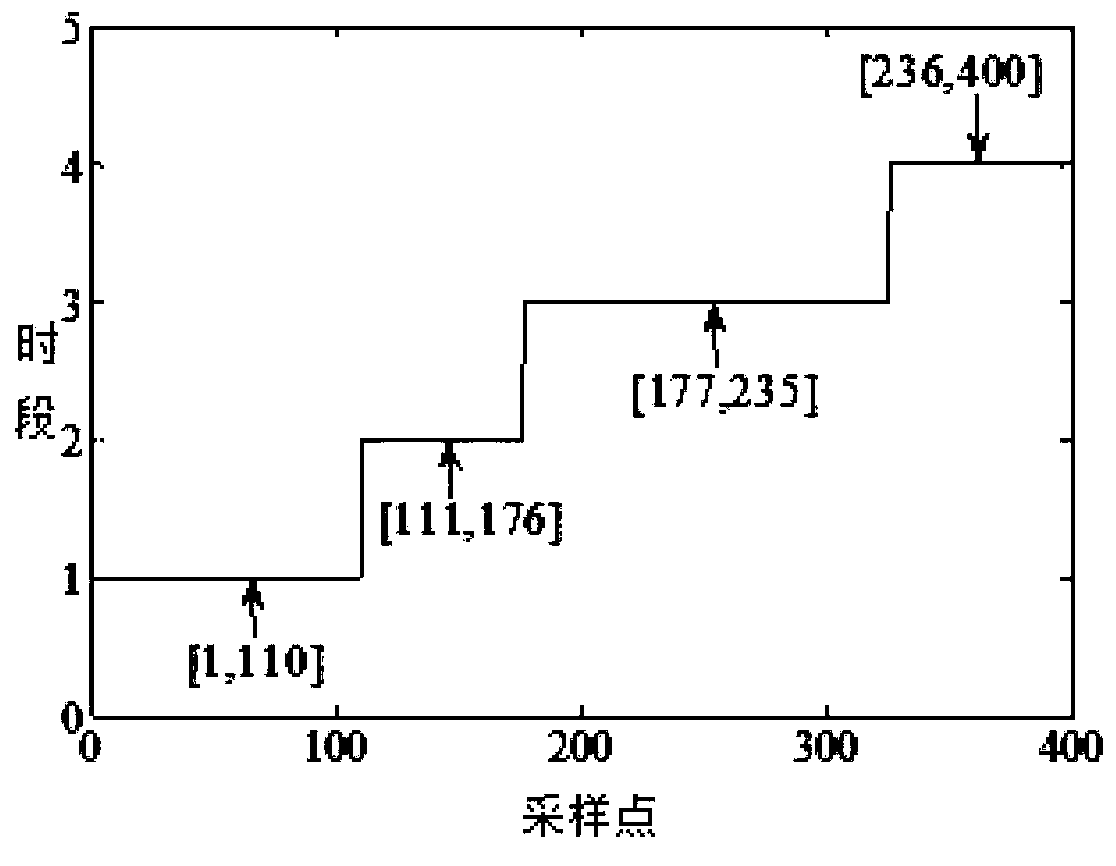

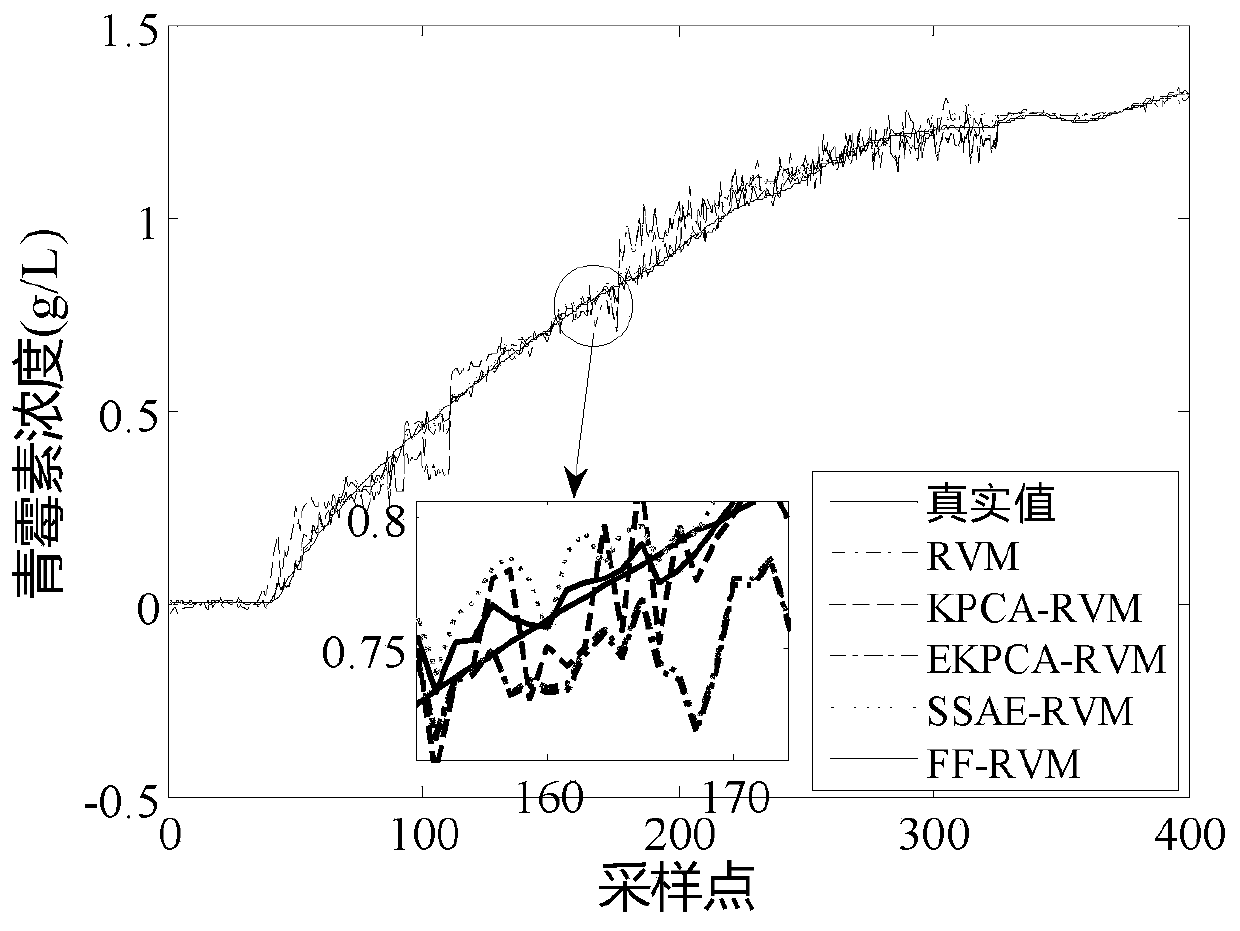

[0053] Penicillin is an antibiotic with extensive clinical value, and its production process is a typical non-linear, dynamic and multi-period batch production process. The penicillin fermentation process simulation platform (PenSim v2.0) was used to generate 10 batches of training data and 5 batches of test data with different initial values, and the sampling time and sampling interval of each batch were 400h and 1h. In the experiment, 11 process variables were selected for the soft-sensing modeling of the penicillin fermentation process, as shown in Table 1, in which the process variables with serial numbers 1-10 are auxiliary variables, and the process variables with serial number 11 are quality variables.

[0054] Table 1 Penicillin Fermentation Process Variables

[0055]

[0056] The concrete steps that the present invention is applied to the penicillin fermentation process are as follows:

[0057] Step 1: The collected process data are X (10×10×400) and Y (10×1×400),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com