Machine tool feed system feedforward control method based on GMDH (Group Method of Data Handling) data mining algorithm

A feed system and data mining technology, applied in the field of CNC machine tools, can solve problems such as deteriorating tracking performance, and achieve the effect of improving tracking accuracy and fast tracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

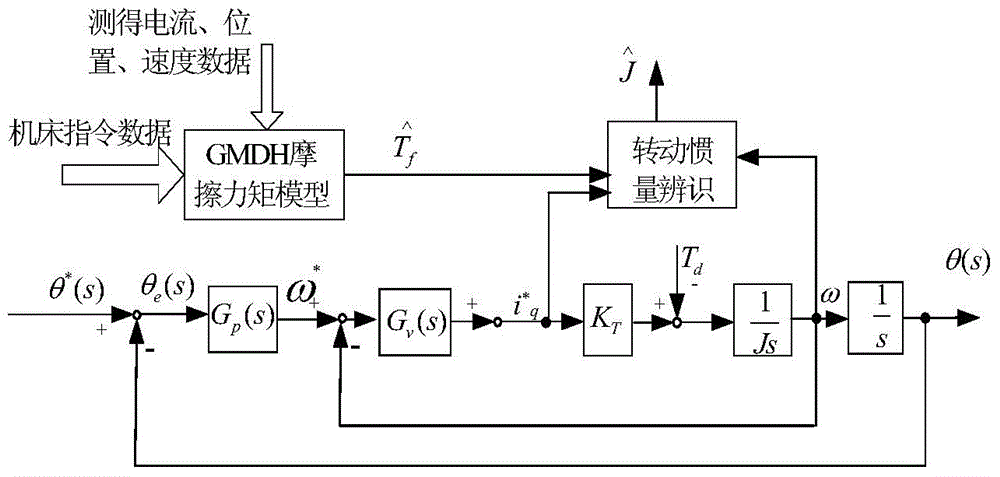

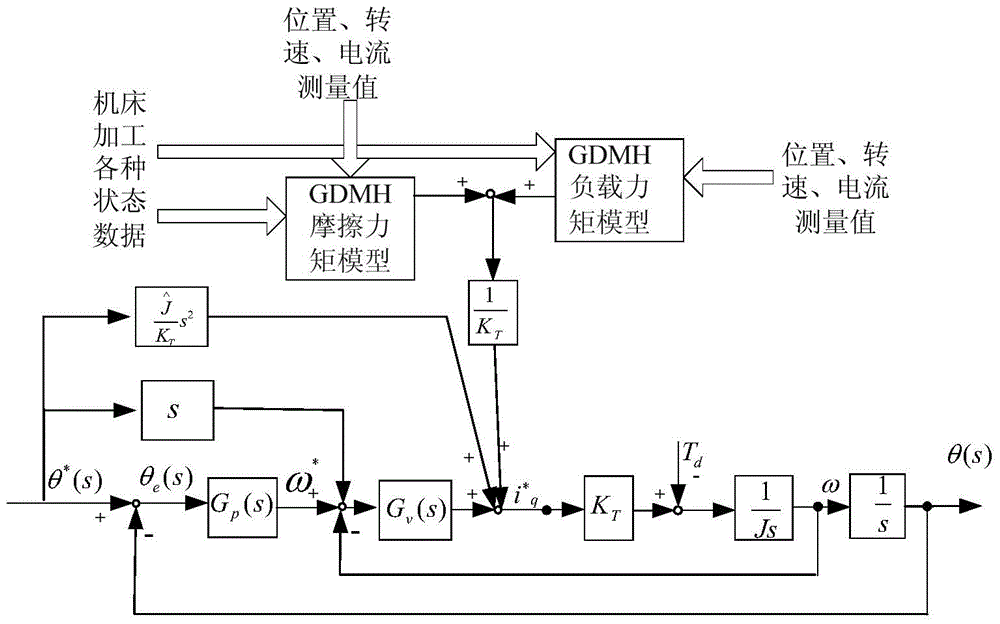

[0026] Such as figure 1 , 2 shown.

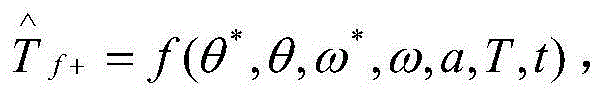

[0027] A feed-forward control method of machine tool feed system based on GMDH data mining algorithm, which collects and stores various state data of the machine tool during no-load and processing. According to the state data of no-load and constant speed, the friction torque is obtained, and then the mathematical model of the friction torque and the state quantities of the machine tool is established when the feed system is no-load by using the GMDH method. Obtaining Moment of Inertia of Feed System Using Observer Method to perform the operation ( figure 2 ) and then applied to the command feedforward compensation. According to the state data of the machining process, the mathematical model of the load torque and each state quantity of the machine tool is established by using the GMDH method. Finally, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com