Process parameter-driven natural gas water dew point online prediction method

A technology of process parameters and prediction methods, applied in prediction, neural learning methods, data processing applications, etc., can solve the problems of easy damage of detectors, high detection cost and impact relationship, and achieve the effect of high detection cost and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

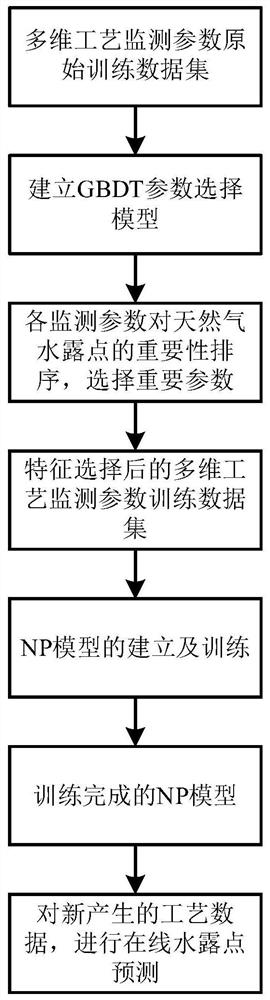

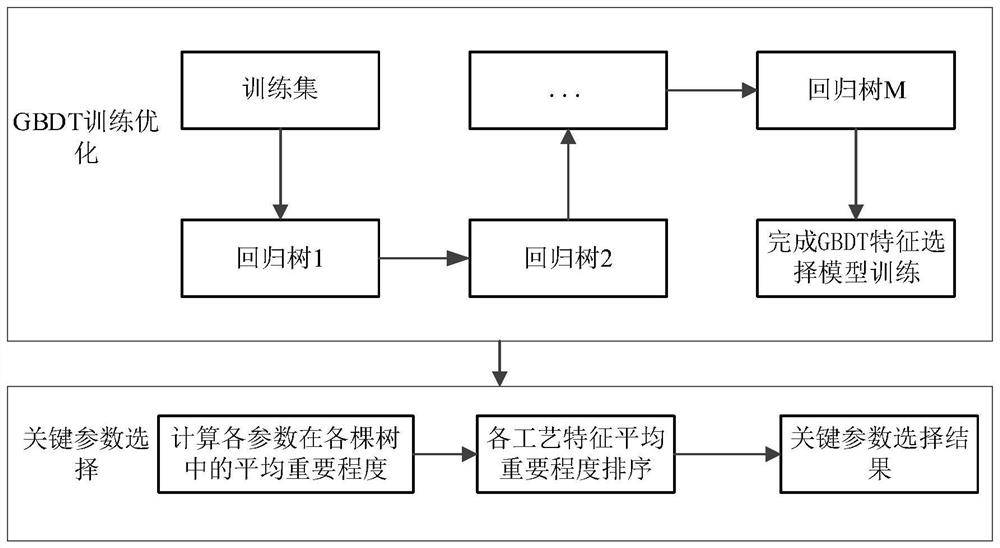

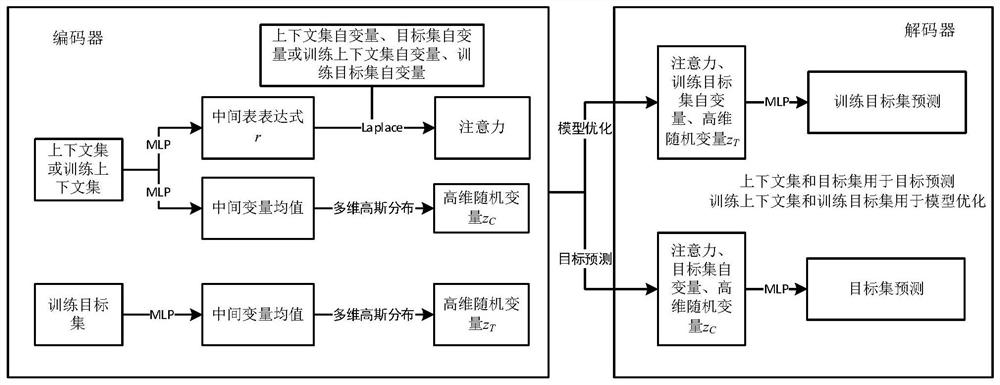

[0024] The realization flow chart of an online prediction method of natural gas water dew point driven by process parameters in the present invention is as follows figure 1 shown, including the following steps:

[0025] Step S1: For a dehydration system with N process monitoring parameters, each parameter is sequentially numbered as parameter 1 to parameter N, N process parameters and historical monitoring data of natural gas water dew point form the original training data set of the prediction model, and the data set has a total of P Each sample is sequentially numbered as sample 1 to sample P, the data set uses N process parameters as variables, and the natural gas water dew point as the label or target value;

[0026] For example, for a natural gas triethylene glycol dehydration device, the monitoring parameters include the absorption tower pressure of each sub-component, the circulation volume of triethylene glycol, the liquid level of the flash tank, the opening of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com