Packing box suspension shock absorber and packing box utilizing same

A packing box and shock absorber technology, which is applied in the directions of transportation and packaging, packaging of vulnerable items, types of packaged items, etc. It can solve the problems of equipment not allowed to squeeze, characteristics of non-linear vibration damping devices difficult to determine, and poor vibration damping effect, etc. problem, to achieve the effect of simple structure, avoiding resonance and avoiding collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

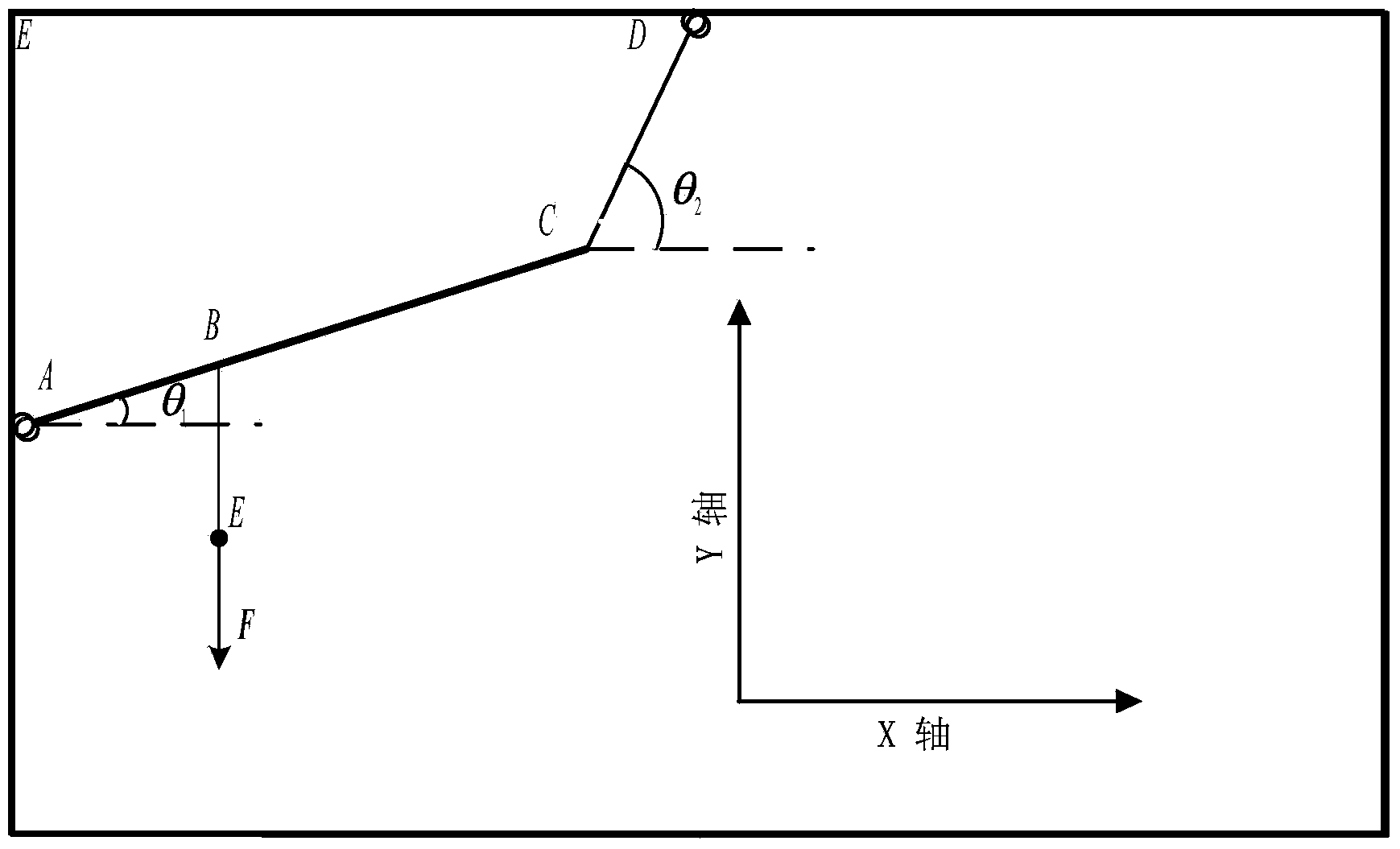

[0024] This embodiment provides a suspension shock absorber for a packing box, including: a suspension rope, a rigid beam and a suspension spring, one end of the suspension rope is used to suspend the product, and the other end of the suspension rope is connected to On the rigid beam, one end of the rigid beam is connected to one end of the suspension spring.

[0025] Further, the suspension spring is connected to the rigid beam at a certain angle along the horizontal direction.

[0026] Further, the angle is less than 90°.

[0027] Further, the suspension rope is made of steel wire.

[0028] Further, the rigid beam adopts a steel structure.

Embodiment 2

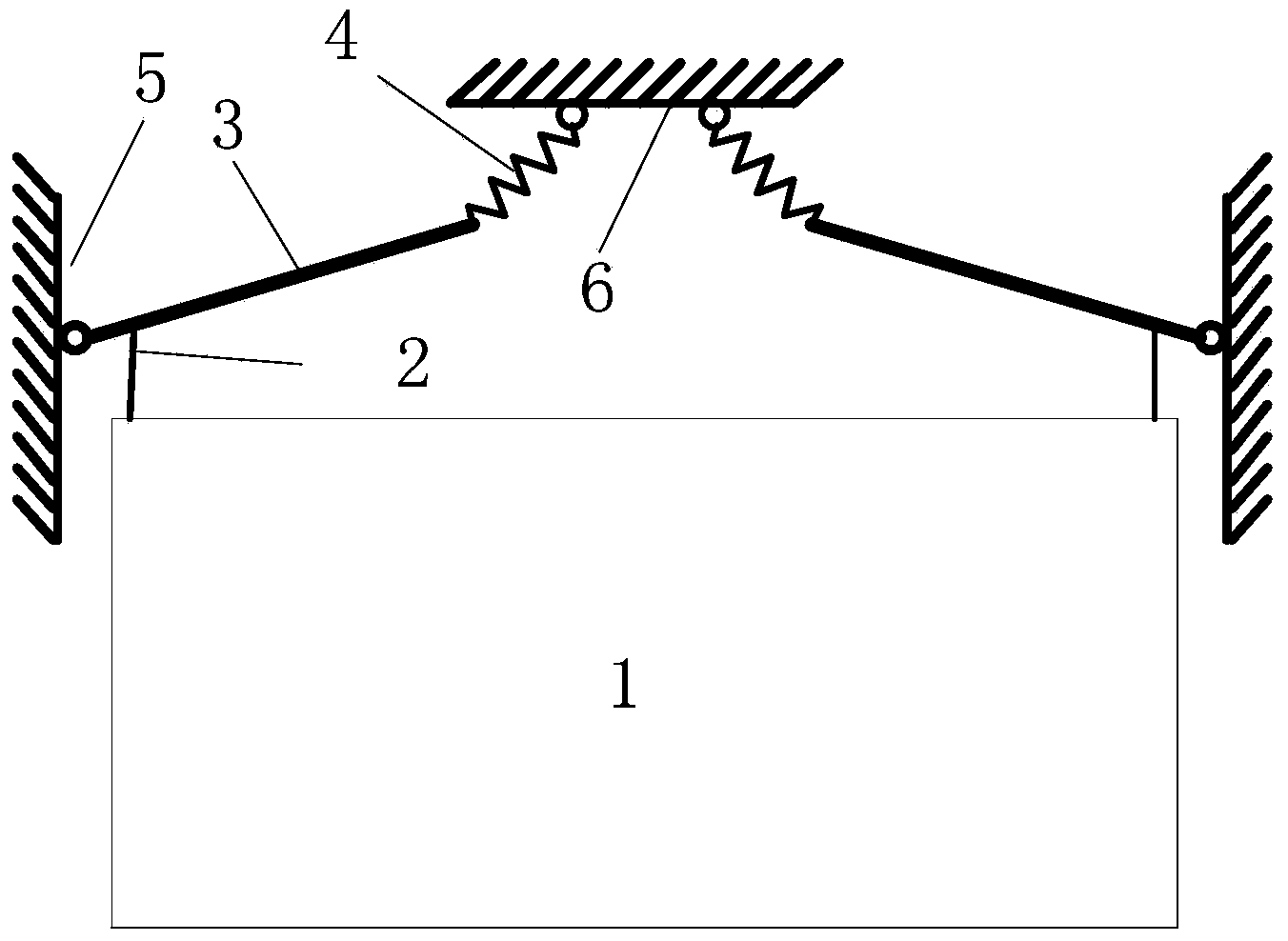

[0030] This embodiment provides a packaging box, including a box body and several groups of the box suspension shock absorbers provided in Embodiment 1 provided inside the box body, wherein the other end of the rigid beam is connected to the side of the box body On the wall, the other end of the suspension spring is connected to the top wall of the box, and the product is suspended inside the box by a suspension rope.

[0031] Further, multiple groups of the packing box suspension shock absorbers are evenly distributed inside the box body.

[0032] Further, the suspension rope is connected to a point on the rigid beam close to the side wall of the box.

[0033] Further, the length between the suspension point of the suspension rope and the connection point of the rigid beam and the side wall is shorter than the length between the connection point of the rigid beam and the side wall to the connection point of the rigid beam and the suspension spring.

[0034] Further, when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com