Spherical hinge type ultralow frequency universal vibration tuning mass damper

A tuned mass damping and ultra-low frequency technology, which is applied in the field of tuned vibration reduction, can solve the problems of high installation cost and large space occupation, and achieve the effects of small stiffness, adjustable position, and reduced frictional resistance torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

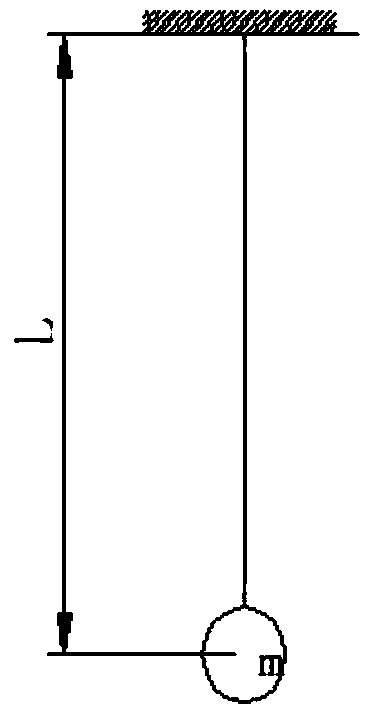

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] see Figure 5 , Image 6 , Figure 7 , the spherical hinge type ultra-low frequency universal vibration tuned mass damper (abbreviation: HLTMD) of this embodiment is supported by 4 vertical columns 1, and the 4 columns 1 are evenly fixed on the bottom plate 2 along the circumferential line, and the bottom plate 2 is fixed On the interlayer board of the tower tube. A spherical hinge is installed at the center of the base plate 2; as can be seen from the figure, the spherical hinge includes a hinge seat 3 fixed to the center of the circumference of the column 1 on the base plate 2, and the center of the hinge seat 3 is provided with a spherical groove. A hinge center ball 4 is correspondingly installed in the groove, and the upper part of the hinge center ball 4 is affixed to the lower end of the vertical center swing rod 5; a drag red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com