Pickaxe-shaped pick

A pick and pick-type technology, which is applied in the field of picks, can solve the problems of uneven wear of picks, shedding of hard alloy cutter heads, and high consumption, so as to improve the life of picks, reduce consumption of picks, and uniform wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

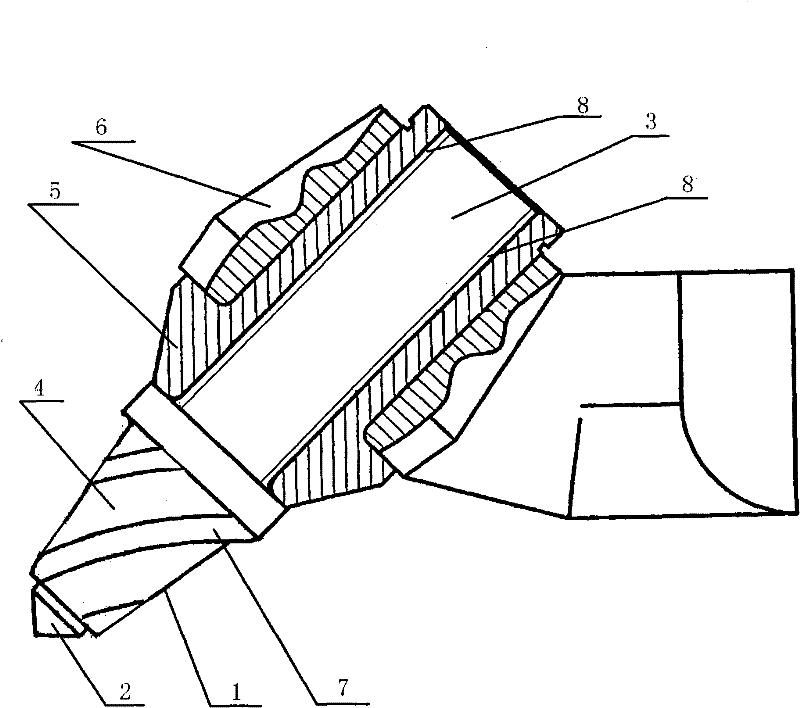

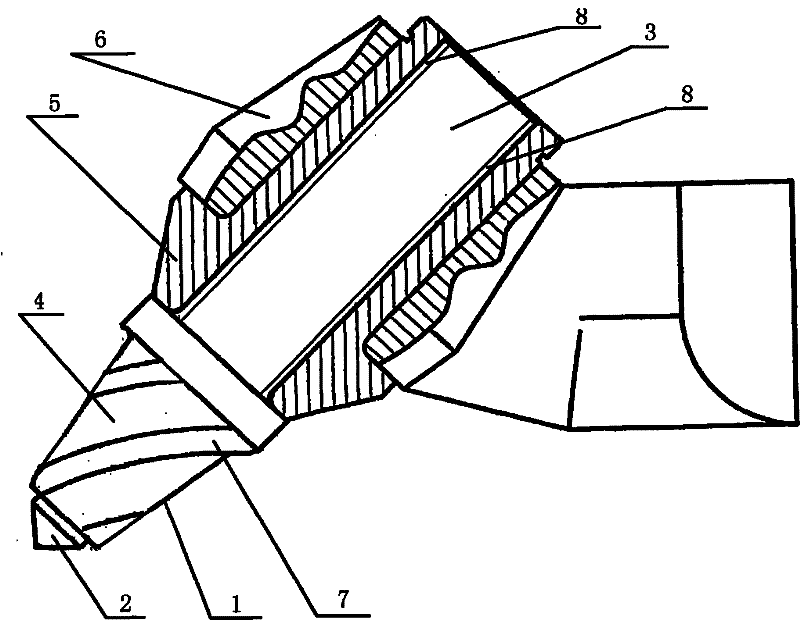

[0015] see figure 1 , a pick-type pick, including a pick body and a hard alloy bit 2, the pick body is composed of a pick head 1 and a pick shank 3, and the hard alloy bit 2 is embedded in the pick The front end of the tooth head 1, the said pick head 1 is in the shape of a truncated cone, the conical surface of the said pick head 1 is provided with three spiral ribs 7, and the outer surface of the said pick head 1 is provided with hard alloy resistant Abrasive material layer 4, the pick shank 3 is inserted into the tooth shoe 5 and cooperates with the tooth shoe 5 as a shaft and sleeve, the outer surface of the pick shank 3 is coated with a solid lubricating film layer 8, and the The tooth shoe 5 is fixed on the tooth holder 6 .

[0016] The embodiment is only for the convenience of understanding the technical solution of the present invention, and does not constitute a limitation to the protection scope of the present invention. Any simple modification, equivalent change an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com