Low damping rotating device and method of operation thereof

A rotating device and low damping technology, which is applied in the field of precision mechanics, can solve the problems that low damping rotating devices are difficult to realize, and achieve the effect of reducing the rotational frictional resistance moment and frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

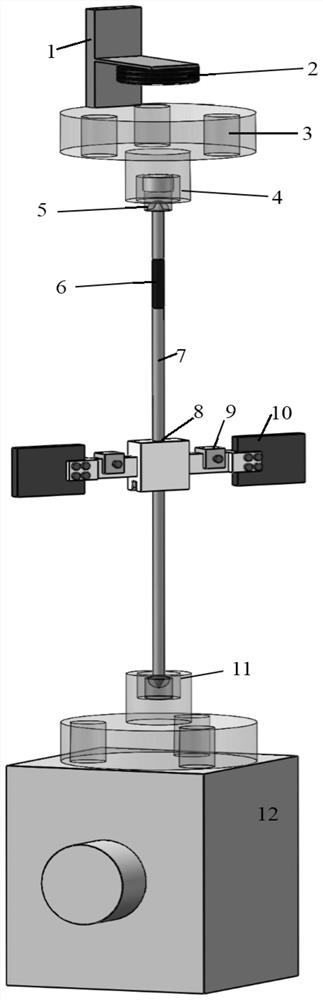

[0045] This embodiment provides a low damping rotating device, such as figure 1As shown, the low-damping rotating device includes a rotating part and a fixed part, wherein: the rotating part includes a vertically placed rotating shaft 7 and a magnet module fixed on the rotating shaft 7; The first permanent magnet 2 and the first jewel bearing 5 above the rotating shaft 7, and the second jewel bearing 11 below the rotating shaft 7; the rotating shaft 7 is covered by the first jewel bearing 5 and the first jewel bearing 5. The two jewel bearings 11 are clamped and rotated; the magnet module and the first permanent magnet 2 generate an attractive force, and by adjusting the vertical position of the first permanent magnet 2, the rotation shaft 7 is adjusted to the second jewel. The pressure of the bearing 11. Among them: the magnet module on the rotating shaft 7 and the first permanent magnet 2 arranged on the upper fixed part generate an attractive force, and by precisely adjust...

Embodiment 2

[0055] This embodiment provides an operation method of the low-damping rotating device as described in the previous embodiment, including: installing the target 10 according to actual needs, fastening the screw knob with the target clamping device 8, and adjusting the matching smooth block 9 The position of the target clamping device 8 balances the weight distribution. After the rotating shaft 7 is installed between the first jewel bearing 5 and the second jewel bearing 11, by adjusting the upper and lower positions of the first permanent magnet 2, the attractive force of the first permanent magnet 2 to the rotating shaft 7 can better offset the rotating part. Own gravity reduces rotational damping.

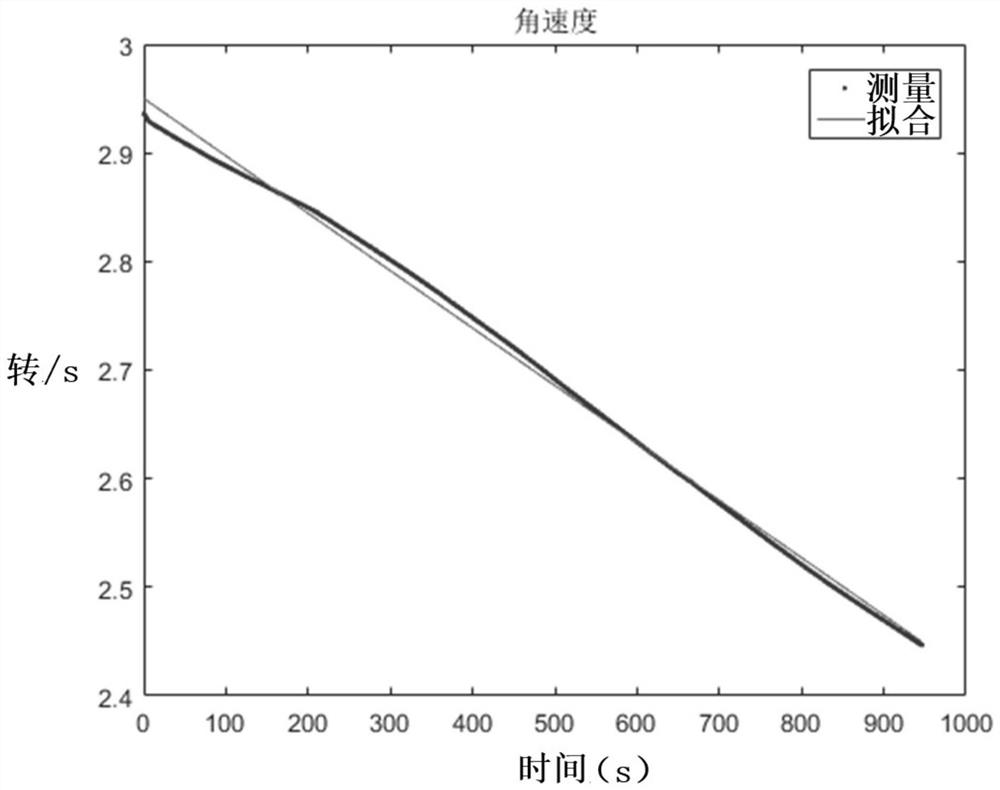

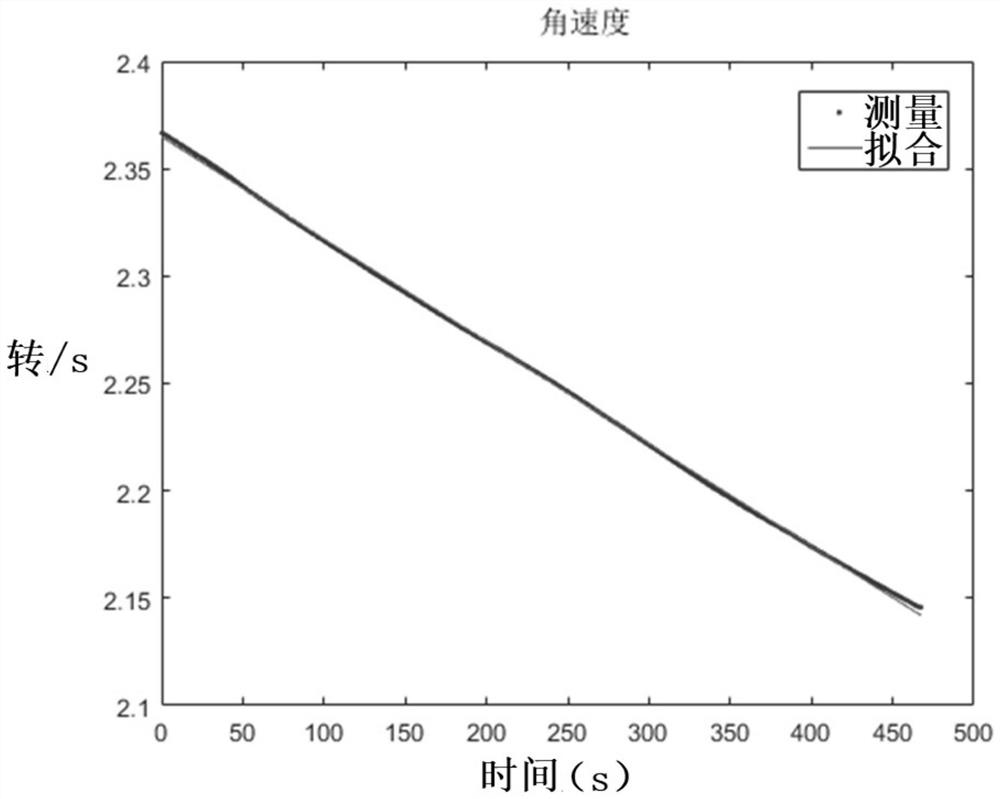

[0056] Further, the low-damping rotating device is placed in an atmospheric environment. When the rotating part is in a static state, the airflow ejected from the air injection device blows to the rotating part, and the torque generated by the airflow makes the rotating part Sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| damping | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com