Magnetic-repulsion automatic constant-pressure feeding device

A feeding device and magnetic repulsion technology, applied in the field of mechanical grinding, can solve the problems of large damping, complex mechanical structure, inaccurate pressure control, etc., and achieve the effects of small frictional resistance torque, high transmission efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

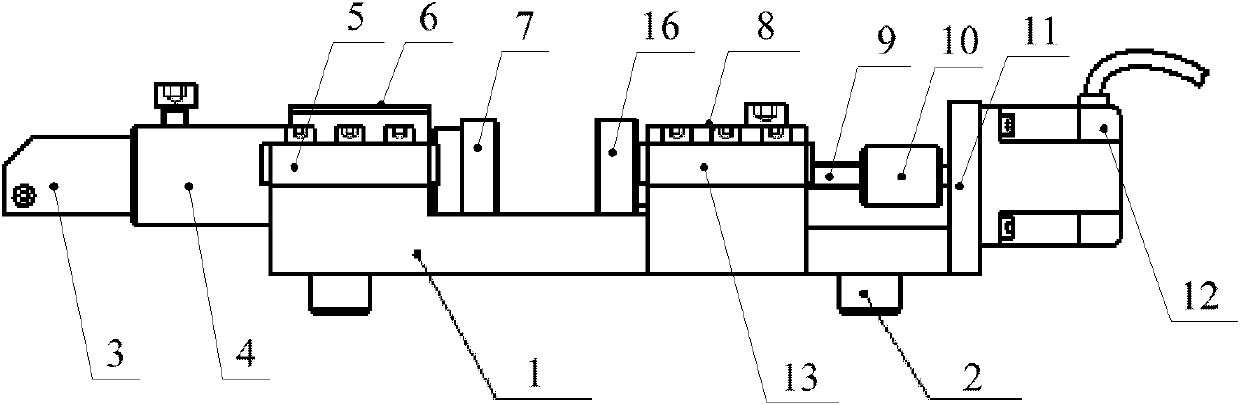

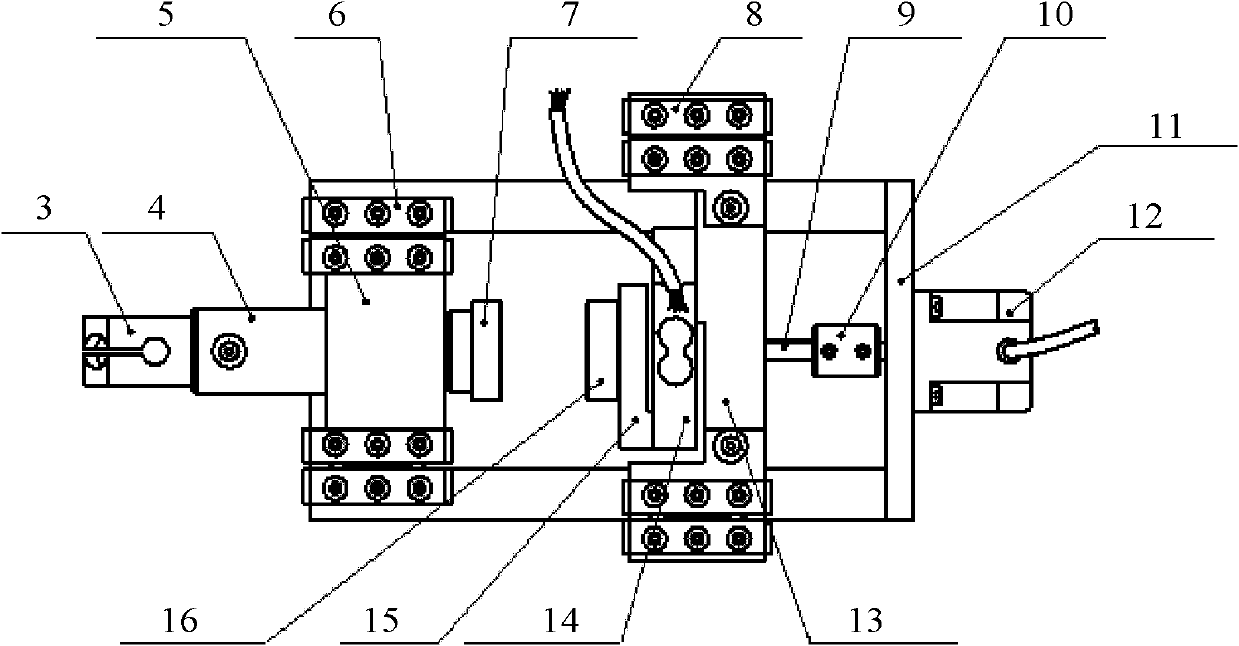

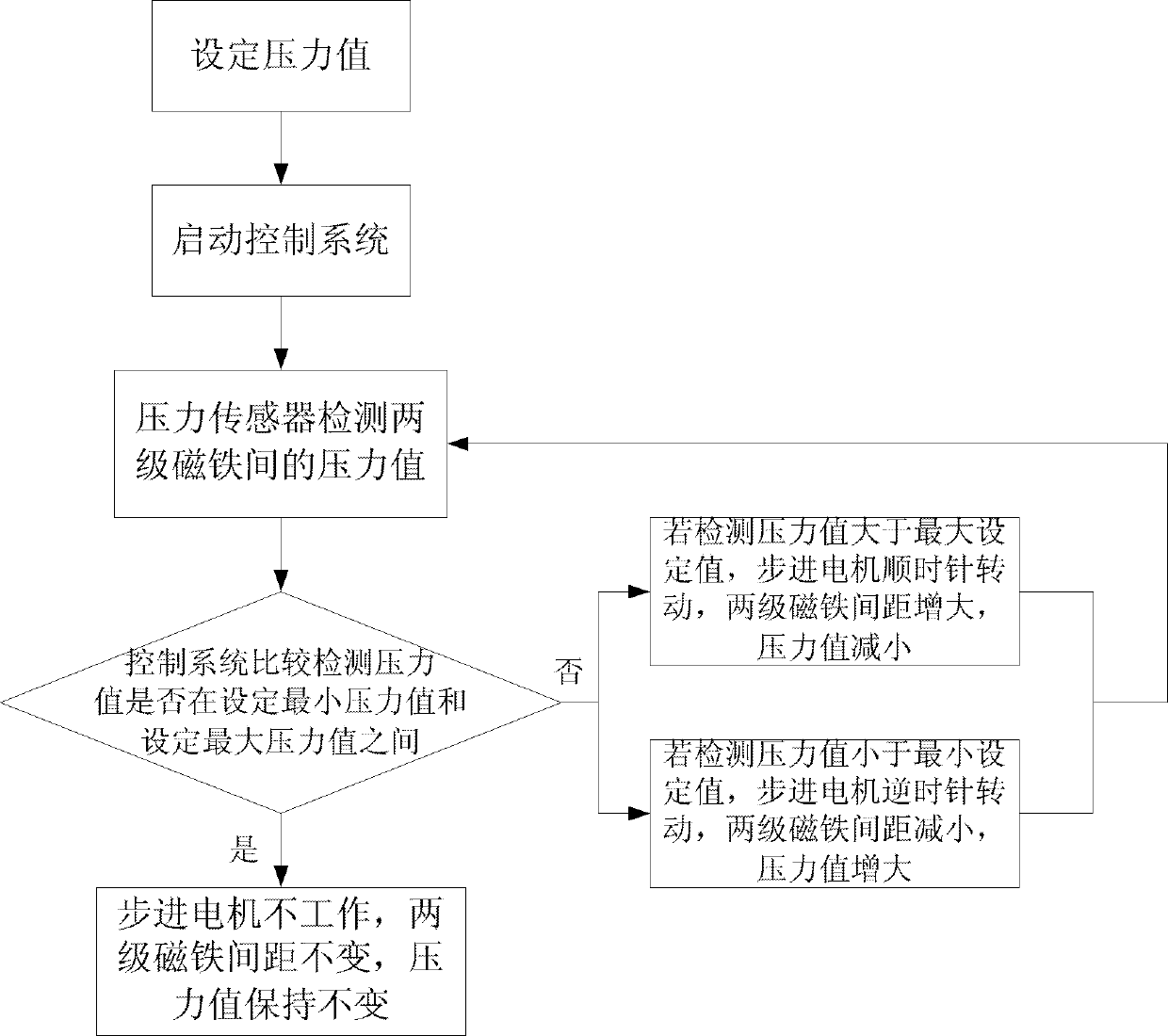

[0026] refer to figure 1 and figure 2 , is the structural front view and top view of the magnetic repulsion automatic constant pressure feeding device according to the embodiment of the present invention. The device mainly includes several feet 2 for supporting the whole device, a base 1 set on the feet 2, The magnetic repulsion force feed mechanism on the base 1, the drive mechanism for driving the magnetic repulsion force feed mechanism to move, and the constant pressure feed control system for controlling the action of the drive mechanism.

[0027] Wherein, the magnetic repulsion feeding mechanism includes a front-stage moving unit and a rear-stage moving unit. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com