Fast tool servo device with adjustable rigidity

An adjustable, servo technology, used in metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve problems such as can not be adjusted according to specific conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

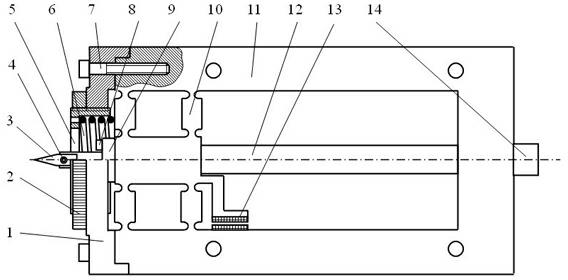

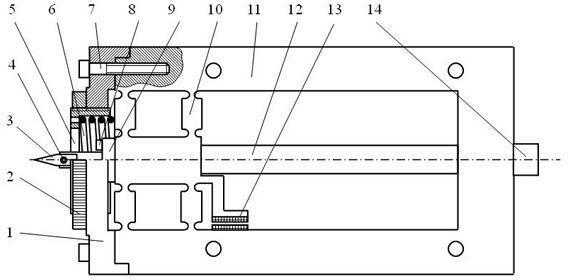

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0021] Cut out the frame 11 and the flexible hinge 10 on a whole piece of metal. On the central axis of the frame 11, the piezoelectric ceramic 12 is installed between the back beam of the frame 11 and the flexible hinge 10, and the other end of the flexible hinge 10 is connected to the tool holder. 9. Install prestressed bolts 14 on the rear beam of the frame 11 and connect the other end of the piezoelectric ceramic 12; the prestressed force can be adjusted through the prestressed bolts 14. The front end of the frame 11 is equipped with a knife rest assembly, and the diamond tool 3 is supported by the knife rest assembly and connected to the knife seat 9; the flexible hinge 10 is connected to the sensor 13 . The position sensor 13 can be used to detect the displacement of the flexible hinge. This displacement is the displacement of the diamond tool.

[0022] The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com