Mechanical multidirectional absorber

A mechanical shock absorber technology, which is applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of shock absorber stiffness performance and vibration reduction effect that no one can explain clearly, cannot satisfy, and is easy to leak. Achieve the effects of ensuring personal and equipment safety, improving drilling efficiency, and reducing fatigue failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

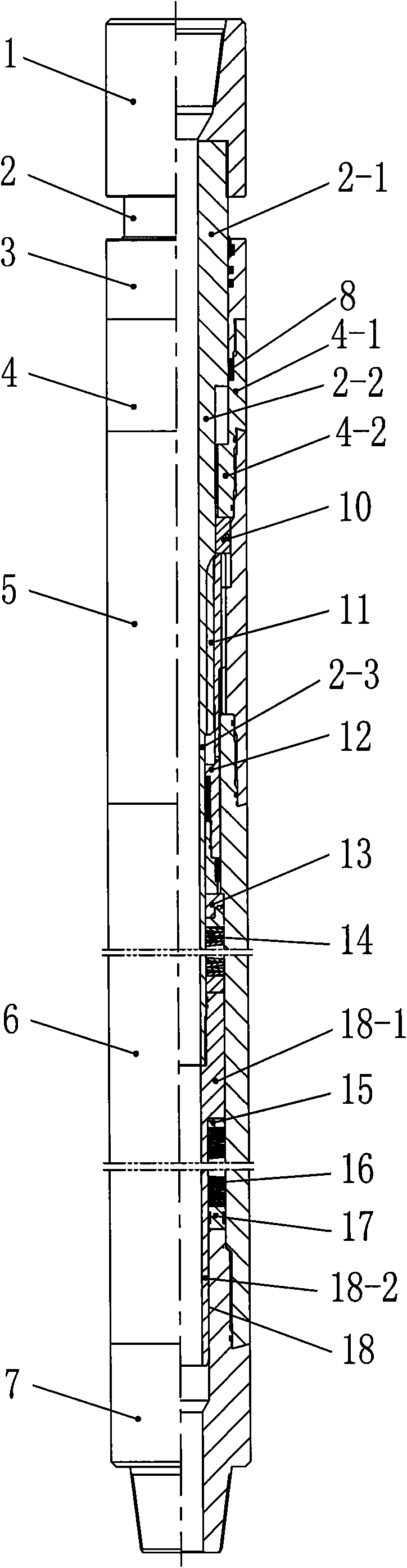

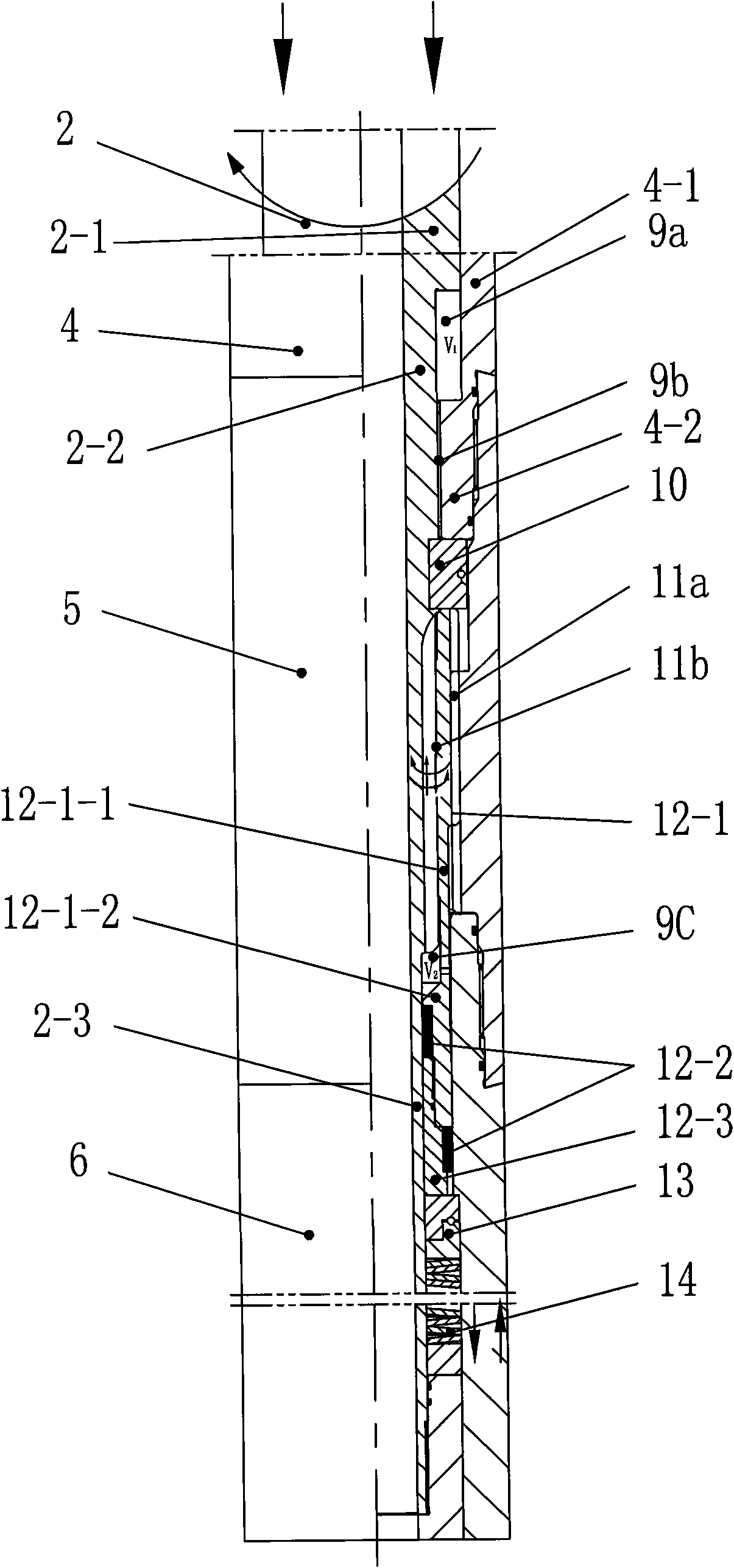

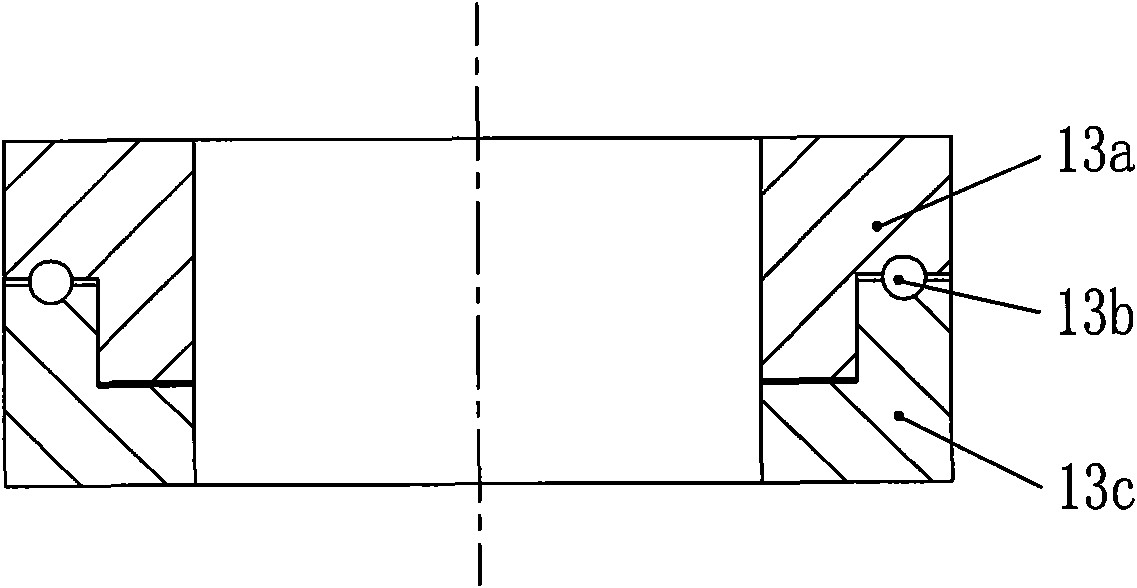

[0029] Such as figure 1 , 2 As shown, the mechanical multi-directional shock absorber includes an upper joint 1, and the lower end of the upper joint 2 is screwed to the mandrel 2. The mandrel 2 includes a large outer diameter mandrel 2- 1. The middle and outer diameter mandrel 2-2 and the small outer diameter mandrel 2-3, the large outer diameter mandrel 2-1 is covered with the mud scraping ring seat 3, the lower end of the mud scraping ring seat 3 is threadedly connected with the centralizing cylinder 4, and the centralizing The cylinder 4 includes a centralizing cylinder 4-1 with a large inner diameter and a centralizing cylinder 4-2 with a small inner diameter from top to bottom. The lower end of the centralizing cylinder 4-2 with a small inner diameter is externally threaded to the spline cylinder 5, and the lower end of the spline cylinder 5 is connected to the internal thread The guide cylinder 6, the lower end of the guide cylinder 6 is internally threaded to connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com