Dynamic vibration absorber capable of improving NVH and matching method thereof

A technology of dynamic vibration absorber and matching method, which is applied in the direction of shock absorbers, instruments, shock absorbers, etc., can solve the problems of many processes, consume a lot of manpower and financial resources, and quickly solve unfavorable resonance problems, so as to achieve the effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

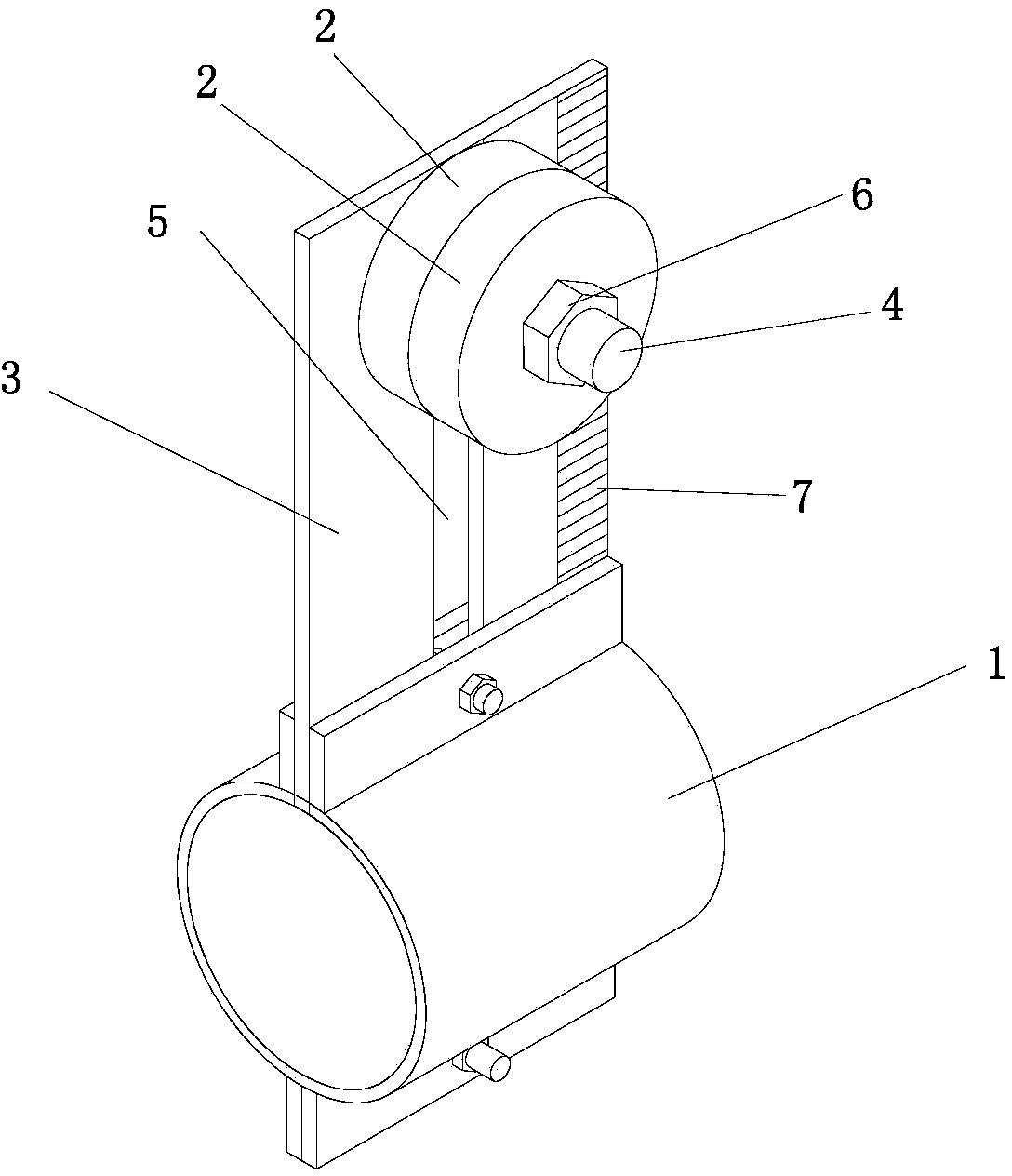

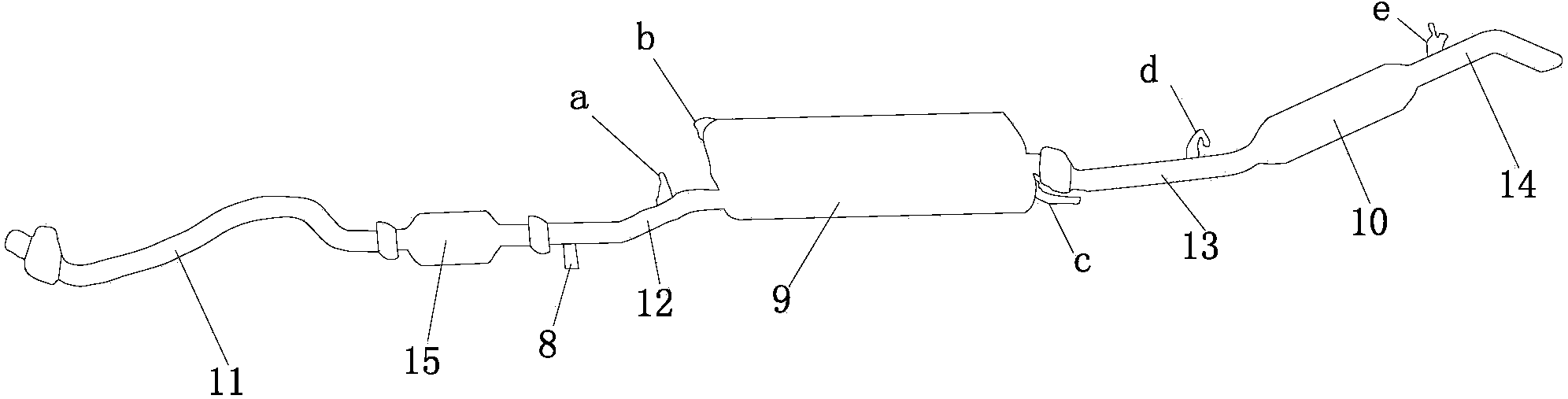

[0048] A dynamic shock absorber needs to be installed on the exhaust system of a certain model.

[0049] Such as image 3 As shown, the exhaust system includes a catalytic converter 15, a middle muffler 9 and a rear muffler 10. One end of the catalytic converter 14 is connected to the gas outlet end of the automobile engine through the first exhaust pipe 11, and the other end of the catalytic converter 14 is connected to the middle muffler 9. One end is connected by the second exhaust pipe 12, the other end of the middle muffler 9 is connected with an end of the rear muffler 10 by the third exhaust pipe 13, and the other end of the rear muffler 10 is connected with an exhaust tailpipe 14.

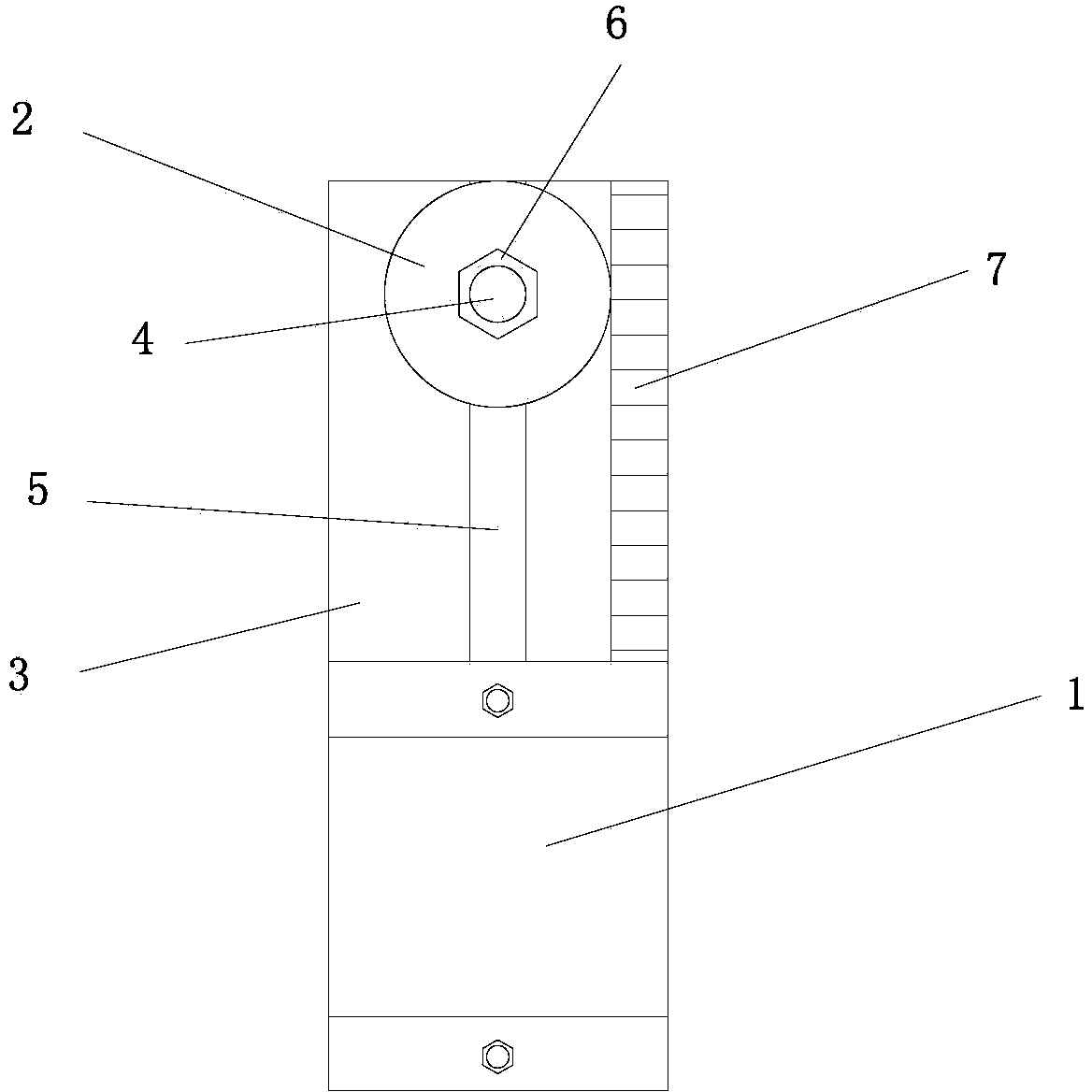

[0050] The matching method of the dynamic vibration absorber, the steps are as follows:

[0051] (1) Draw the different scale positions of the mass block 2 on the leaf spring 3 and the natural frequency table of the dynamic vibration absorber under different counterweights (as shown in Tab...

Embodiment 2

[0062] For the exhaust system of another vehicle type, the matching method of the present invention is used to match the dynamic vibration absorber. When the dynamic vibration absorber is not installed, the frequency is 24Hz, which is just within the engine excitation frequency range of 24-26Hz. There is a hidden danger of resonance. After the shock absorber, the frequency is reduced to 20.35Hz, effectively avoiding the engine excitation frequency.

[0063] To sum up, for different systems of the whole vehicle, such as exhaust system, steering system, suspension system, etc., there can be a general dynamic vibration absorber, only need to adopt the matching method of the present invention according to the natural frequency of different systems, Adjusting the position of the mass on the plate spring and the counterweight of the mass to obtain a matching dynamic vibration absorber can quickly and efficiently solve the resonance problem and has high application value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com