Variable-speed manipulator assembly

A technology for variable speed manipulators and assemblies, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., to achieve the effects of simple and convenient installation, reduced manufacturing costs, and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] In order to further illustrate the technical solution of the present invention and the beneficial effects brought by it, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

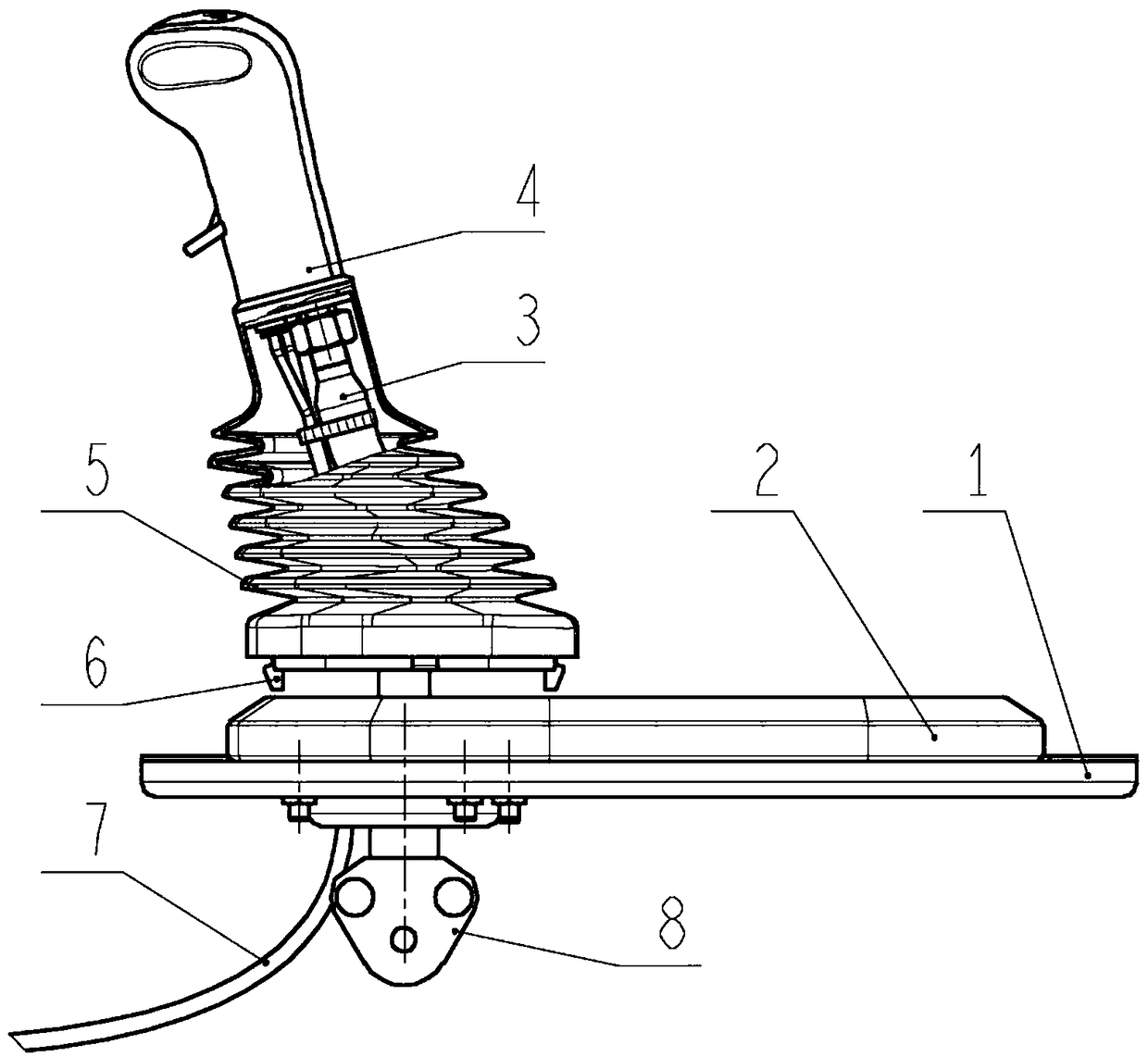

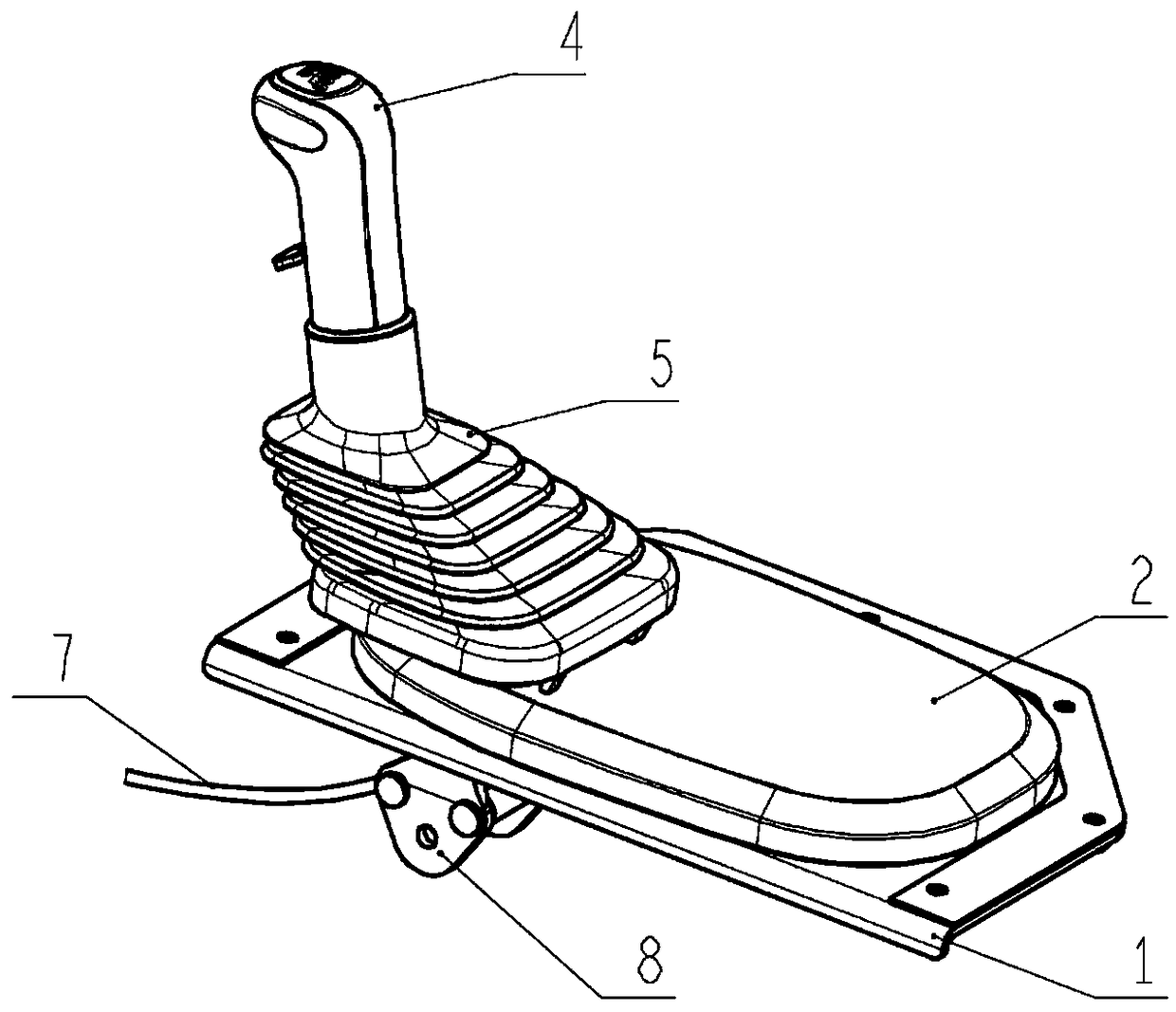

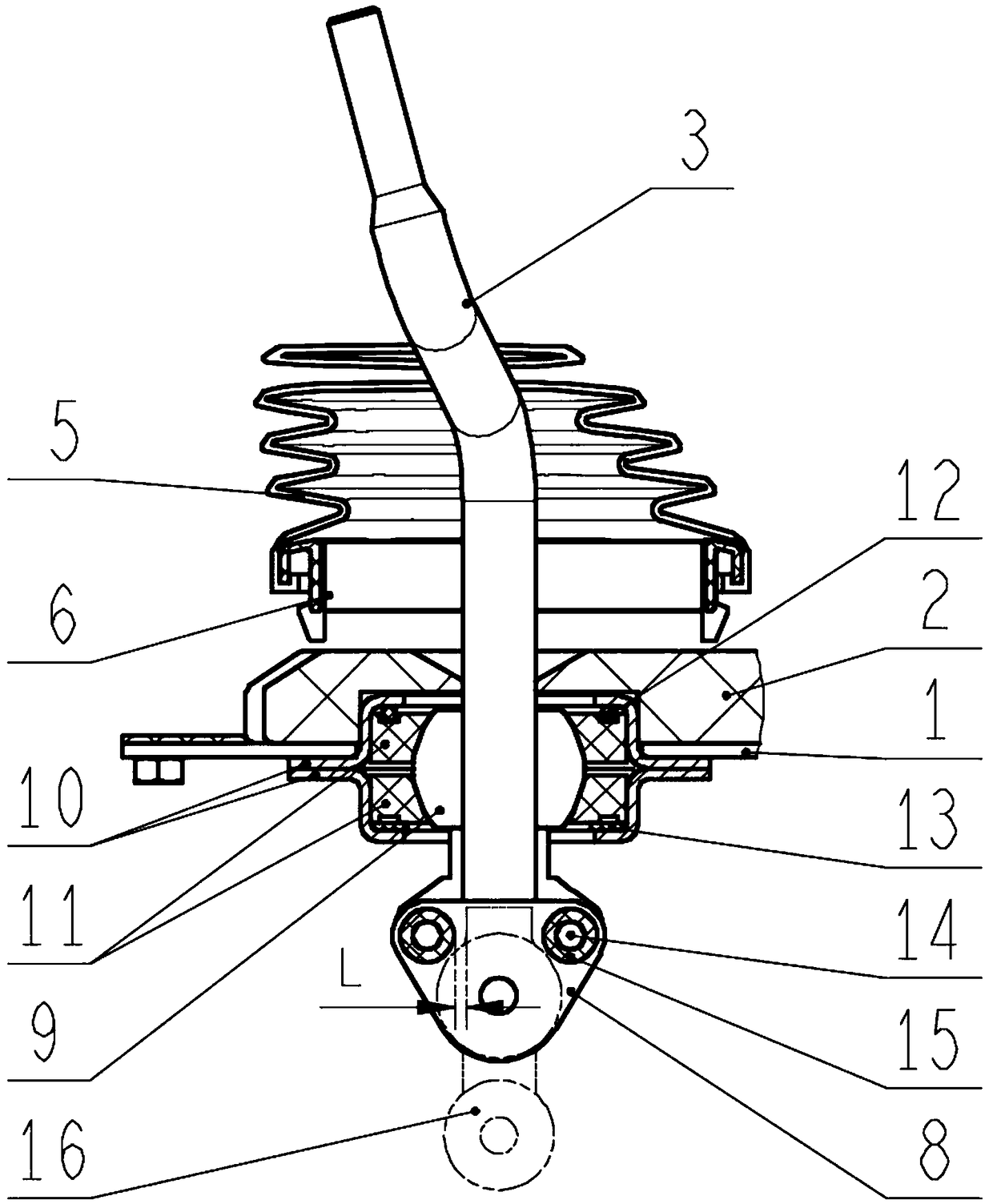

[0032] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a variable speed manipulator assembly, which consists of a mounting plate 1, a sealing ring 2, a joystick 3, a handle 4, a sheath 5, a buckle 6, an air pipe 7, a connecting arm assembly 8, a ball head 9 and the ball head assembly.

[0033] Such as figure 2 and image 3 As shown, the edges of the left and right sides (or front and rear sides) of the mounting plate 1 are provided with flanges vertically downward, and the flanges are used to enhance the supporting strength of the mounting plate 1 to prevent deformation of the mounting plate 1; A sealing gasket is pasted around the upper surface of the mounting plate 1, and the mounting plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com