Solar vacuum energy exchange thermal-collecting tube

A heat collecting tube and vacuum technology, which is applied in the field of solar vacuum energy-conversion heat collecting tubes, can solve the problems of large heat loss, increased heat loss, and increased outgassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

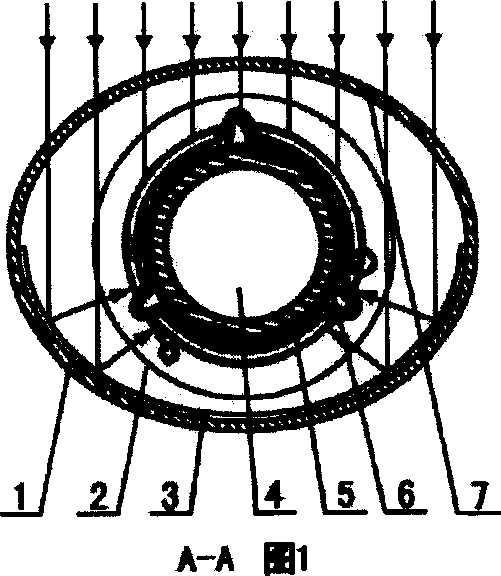

[0067]The first embodiment: a single-pass variable diameter single-layer tube head solar vacuum energy conversion heat collection tube provided by the present invention includes a glass positioning nozzle, 13, an inner energy conversion tube 5 and an outer glass tube, and the solar vacuum energy conversion heat collector The connection seal between the outer glass tube of the heat pipe and the inner transducing tube 5 is provided with a variable-diameter blocking step installation sealing surface with a certain heat insulation function. , between the inner transduction tube 5 and the outer tube is an annular vacuum interlayer 2, the outer wall of the inner transduction tube 5 is coated with a transduction membrane plate 6, and on the inner tube wall of the backlight surface 1 of the outer glass tube of the solar vacuum energy conversion heat collection tube, Composite with a reflective mirror 3, the opening angle of the reflective mirror 3 is ≤180°, and the curved surface refle...

no. 2 example

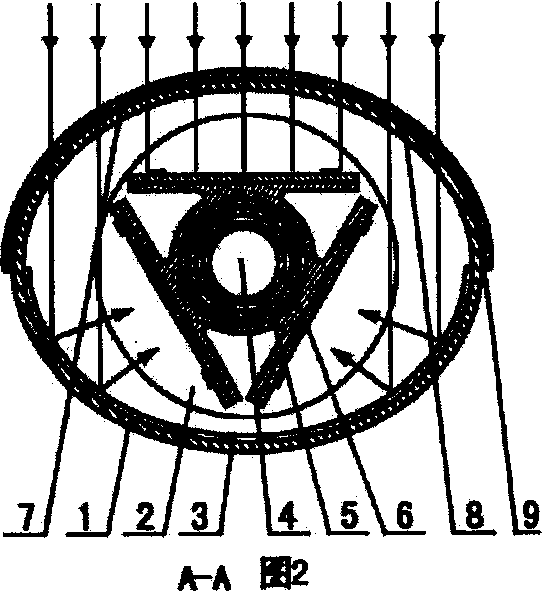

[0068] The second embodiment: the all-glass heat pipe provided by the present invention is equipped with a sealing retaining ring, including heat-conducting working fluid filling and exhaust tailpipe sealing head, heat pipe heat release section 19, metal support bullet clip, and glass explosion-proof safety valve 22. Transducer tube 5, heat exchange medium, glass positioning nozzle 13, variable diameter step mounting sealing surface 14, throttling vapor-liquid heat exchange device 20, transduction membrane plate 6, outer glass tube, and reflective mirror surface 3. The heat-collecting section of the heat-collecting section of the energy-transfer tube 5 with both ends of the glass-welded head is a glass explosion-proof safety valve 22, and the throttling vapor-liquid heat exchange device 20 is positioned concentrically between the heat-collecting section of the energy-transfer tube 5 and the heat pipe through the metal support clip 21. Between the exothermic section 19. One end...

no. 3 example

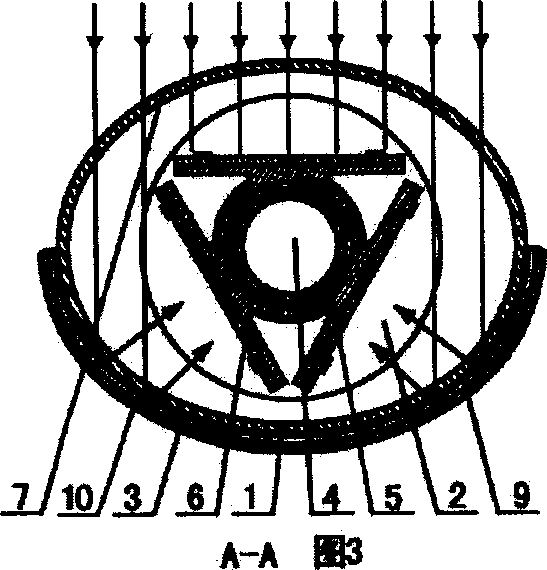

[0070] The third embodiment: on the outer tube wall of the backlight surface 1 of the outer glass tube of the solar vacuum heat collection tube, a reflective mirror surface 3 is bonded and compounded with a transparent glue 9, and the reflective mirror surface 3 is compounded with a composite substrate 10. The elastic electrical connection assembly 15 with a long-lasting getter is sealed and led out through the metal glass sealing head 16 . When in use, the conductor is connected to a DC power supply, so that the conductive heat-absorbing film of the energy conversion tube can be negatively charged, and through induction, the inner wall of the water chamber of the heat collecting tube is charged with positive charges and becomes acidic, preventing metal ions from forming on the inner wall of the heat collecting tube. A photovoltaic cell 18 is compounded on the transducing membrane plate 6 of the transducing tube 5 , and the wires of the photovoltaic cell 18 are sealed and led o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com